The flywheel is mounted to the crank with 6 bolts. Luckily I've taken pics and video all along the way. This is a pic of the end of the crankshaft while at the local Chevy dealership showing how the pilot bearing was bored into by that oversized Pfadt driveshaft.

-

Got the Contributing Memberships stuff finally worked out and made up a thread as a sort of "How-To" to help people figure out how to participate. So if you need help figuring it out, here's the thread you need to take a look at -> http://www.corvetteflorida.com/forums/showthread.php?t=3581 Thank you, everyone! Rich Z.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

427 engine (part 2) - RHS block

- Thread starter Rich Z

- Start date

BTW, the above pic shows why techs should NOT use the hydraulic pressure method of removing the pilot bearing on LS engines. See that plug behind the pilot bearing? There is a good chance that would get pushed into the engine before the pilot bearing would be pushed out. Then you've REALLY got a mess to deal with.

navy2kcoupe

!ereH nI depparT m'I pleH

The flywheel will have to be pretty close to the one already in there, at least

in terms of pilot bearing diameter, and depth, or you're liable to need a new

torque tube (to match up with the new flywheel) as well :face_palm_02:!

Andy :wavey:

in terms of pilot bearing diameter, and depth, or you're liable to need a new

torque tube (to match up with the new flywheel) as well :face_palm_02:!

Andy :wavey:

From what I can see, the LS6 and LS7 flywheels both have 6 bolt holes for mounting to the crankshaft. However, it appears that the LS6 flywheel is uniformly flat across the surface facing the pressure plate, but for the LS7 pressure plate the bearing surface is recessed. Regardless, I will have both flywheel replaced along with the clutch. For one thing, a resurfaced used flywheel was put in there, and from what I understand the GM service manual specifically states to DO NOT resurface the flywheel for reuse.

As for a possible torque tube issue, the torque tube mounts to the bell housing. It appears to me that the end of the crankshaft will take both the smaller LS6 style pilot bearing or the larger LS7 style bearing. As I mentioned that implies to me that the input shaft to the torque tube must be different in the LS6 and LS7 powered vettes. It would have to be shorter in the LS7 in order to use that larger pilot bearing.

If you look at the pic I posted above, you can see where that larger LS7 style bearing would be pressed into the end of the crankshaft.

Here's a video of someone removing an LS3 pilot bearing, which appears to be that same larger style bearing.

https://www.youtube.com/watch?v=c0ZAnN_OqiI

Now, honestly, exactly what years and which exact vehicles used one type of bearing or the other, I really don't know. But I'm guessing putting the wrong style pilot bearing in could cause you a bunch of headaches.

As for a possible torque tube issue, the torque tube mounts to the bell housing. It appears to me that the end of the crankshaft will take both the smaller LS6 style pilot bearing or the larger LS7 style bearing. As I mentioned that implies to me that the input shaft to the torque tube must be different in the LS6 and LS7 powered vettes. It would have to be shorter in the LS7 in order to use that larger pilot bearing.

If you look at the pic I posted above, you can see where that larger LS7 style bearing would be pressed into the end of the crankshaft.

Here's a video of someone removing an LS3 pilot bearing, which appears to be that same larger style bearing.

https://www.youtube.com/watch?v=c0ZAnN_OqiI

Now, honestly, exactly what years and which exact vehicles used one type of bearing or the other, I really don't know. But I'm guessing putting the wrong style pilot bearing in could cause you a bunch of headaches.

7 Things You Should Know About the RHS LS Block

Well, it certainly looks like the RHS block in my engine is a quality piece of equipment.

https://www.youtube.com/watch?v=8RXVo03kYdM

It sure looks a lot better done than that original World Products Warhawk block I got.

https://www.youtube.com/watch?v=KbBdXf9lwZI

All I can say is that I certainly was NOT impressed with the Warhawk engine I got and ultimately rejected.

Well, it certainly looks like the RHS block in my engine is a quality piece of equipment.

https://www.youtube.com/watch?v=8RXVo03kYdM

It sure looks a lot better done than that original World Products Warhawk block I got.

https://www.youtube.com/watch?v=KbBdXf9lwZI

All I can say is that I certainly was NOT impressed with the Warhawk engine I got and ultimately rejected.

So I was sitting on the "throne" listening to thunder getting closer and closer and wondering if I should shut off the computers in case the house or power lines would get hit by a lightning strike. Then that led to me thinking about the possibility of the garage getting struck by lightning and what could be damaged in there. From there I recalled that twice, buildings that the blue C5Z was in, got struck by lightning. Which at the time had me wondering if perhaps the car WAS jinxed and God was trying to tell me something. But the car has been in my own garage now for almost 7 years, with PLENTY of lightning storms during that time, and nary a one has hit the garage with the C5Z in it. Interesting, no?

So what two buildings DID get hit by lightning while the C5Z was in them? The shop owned by Chris Harwood at XtremeMotorsports and the shop owned by Aaron Scott at South Georgia Corvette. Both suffered damage to their equipment in their shops from the lightning strikes, yet no damage to my car. So perhaps God WAS trying to tell me something. Sure wish I had listened.

Of course, it COULD have just been a coincidence. :shrug01:

So what two buildings DID get hit by lightning while the C5Z was in them? The shop owned by Chris Harwood at XtremeMotorsports and the shop owned by Aaron Scott at South Georgia Corvette. Both suffered damage to their equipment in their shops from the lightning strikes, yet no damage to my car. So perhaps God WAS trying to tell me something. Sure wish I had listened.

Of course, it COULD have just been a coincidence. :shrug01:

Darn.... Moved the C5Z out of the lift bay so I could move the Jeep into it so I can do an oil change and tire rotation and noticed that the fuel gauge on the C5Z is only showing about a eighth of a tank of gasoline remaining. Got to get it out to fill the gastank up before it evaporates down to being empty on me.

Didn't hear any drivetrain squealing pulling it in and out of the garage. Sure do wish that car would go ahead and HEAL itself.

Didn't hear any drivetrain squealing pulling it in and out of the garage. Sure do wish that car would go ahead and HEAL itself.

let it go.

Meaning what?

mrr23

The Alignment Guy

Meaning what?

meaning no noise, don't worry about it. probably just something minor.

meaning no noise, don't worry about it. probably just something minor.

Yeah, you are probably right. Probably just the Centerforce clutch being noisy when it wants to. Just wish I could find someone I could trust to at least diagnose the problem, but that is proving to be extraordinarily difficult to do for some reason.

As best I can tell Greg Lovell at AntiVenom has fallen off the face of the earth. :shrug01:

85vette

Active member

Well, as best as I can tell, a new clutch will run in the neighborhood of $1500-$3000 depending on who you get to do it. I was going to take my CTS V to East Coast Corvettes in Maryland until I found out that SS Performance would do it. I believe Mike quoted me $750 for the parts and $750 for the install. Dealer will likely be higher. Bottom line is you need someone who will still be in business and will stand behind their work. That's getting harder to do these days. The dealer is a safe bet most of the time if you can afford their prices.

Yeah, I actually contacted the Service Lane Manager (George Bell) at Dale Earnhardt Chevy here in Tallahassee to ask about having Shane take a look at my car to see if he could figure out what is making the drivetrain noise. After his initial response that he would get with Shane and schedule a time to have me bring my car in, nothing.... A followup email also got no response.

Funny thing is that I had a salesman from them call me up claiming they wanted to buy my C6Z for a customer. Yeah, right. They can just kiss my ass..........

Funny thing is that I had a salesman from them call me up claiming they wanted to buy my C6Z for a customer. Yeah, right. They can just kiss my ass..........

Took the C5Z out for a ride today, and not a peep out of the drivetrain. That is twice in a row now I took the car out, and the drivetrain squeal didn't show up.

I have been working the clutch a bit more aggressively than I normally do, so perhaps that is having a positive effect.

I have been working the clutch a bit more aggressively than I normally do, so perhaps that is having a positive effect.

So the saga continues.....

The C5Z is up on a lift and the drivetrain is out.

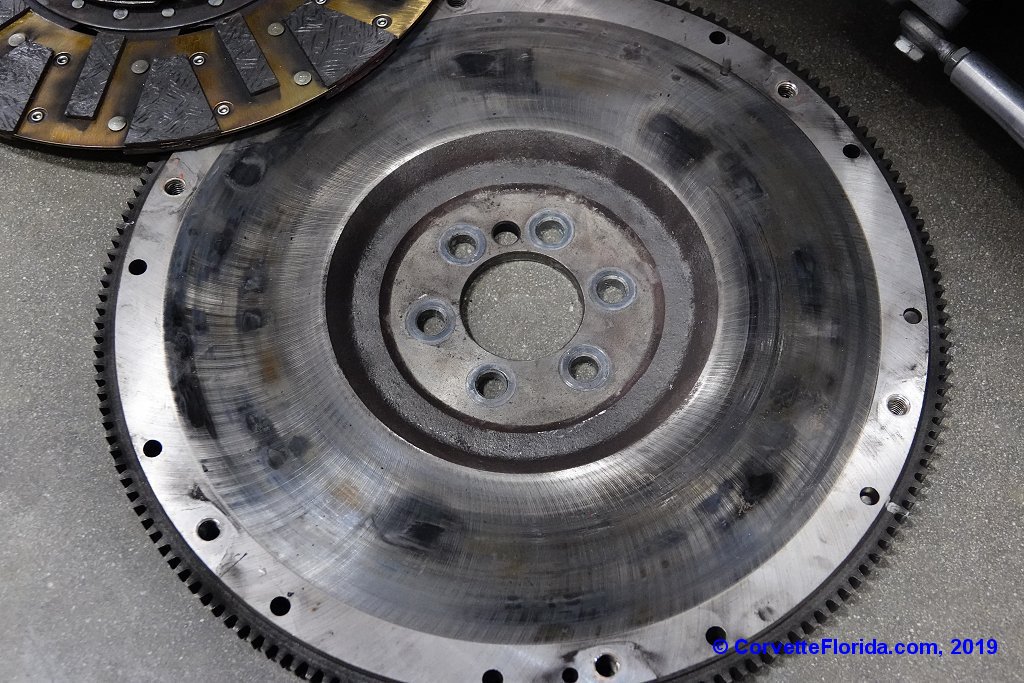

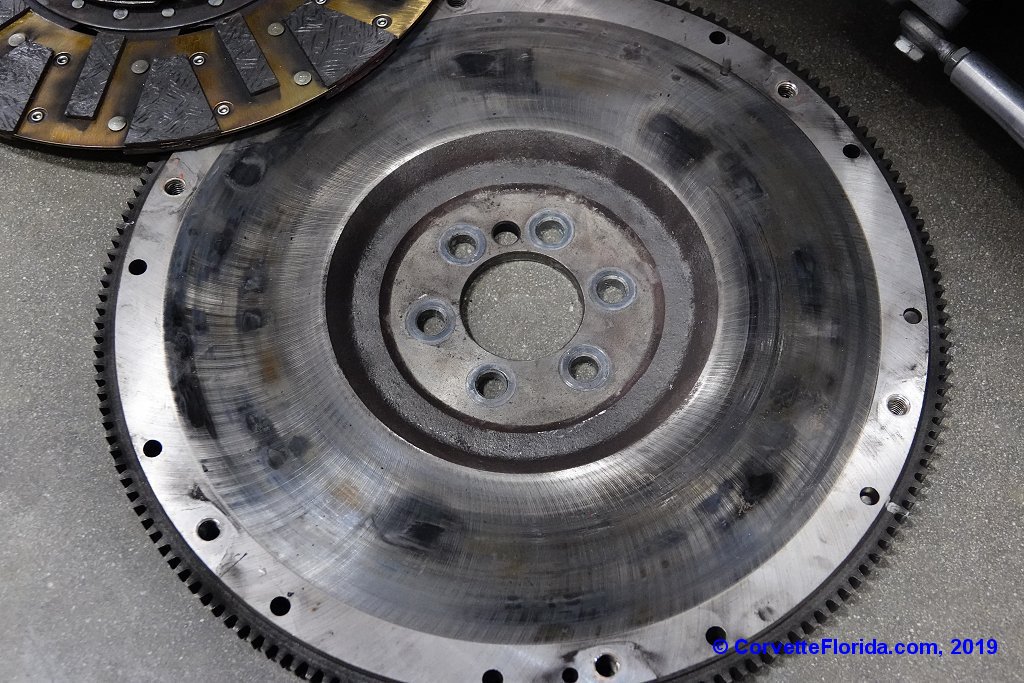

The Centerforce Dual Friction clutch disk looks OK, but the pressure plate and flywheel have noticeable burn marks on them.

Of particular note is the amount of residue of *something* around the pilot bearing. Actually in this case, it is a pilot BUSHING.

There also appears to be some sort of wear striations inside the pilot bushing.

The portion of the torque tube input shaft that rides within the pilot bushing looks like this.

Appears to me that the pilot bushing is damaged. But whether that is the cause of the problem or the result of something else that damaged the bushing, not sure at this point.

I have been talking with RPM Transmissions, and apparently putting in a pilot bushing instead of a pilot bearing is not recommended.

So, the jury is still deliberating....

The C5Z is up on a lift and the drivetrain is out.

The Centerforce Dual Friction clutch disk looks OK, but the pressure plate and flywheel have noticeable burn marks on them.

Of particular note is the amount of residue of *something* around the pilot bearing. Actually in this case, it is a pilot BUSHING.

There also appears to be some sort of wear striations inside the pilot bushing.

The portion of the torque tube input shaft that rides within the pilot bushing looks like this.

Appears to me that the pilot bushing is damaged. But whether that is the cause of the problem or the result of something else that damaged the bushing, not sure at this point.

I have been talking with RPM Transmissions, and apparently putting in a pilot bushing instead of a pilot bearing is not recommended.

So, the jury is still deliberating....

Oh yeah, notice those apparent impact witness marks on that pilot bushing in the upper left hand quadrant? Not sure what caused that. Installation carelessness putting the bushing in, perhaps? Or perhaps putting the torque tube back in didn't go as easily and carefully as one would hope?

Perhaps the front bearing of the torque tube holding the input shaft got damaged when the torque tube was installed?

:shrug01: :shrug01: :shrug01:

Perhaps the front bearing of the torque tube holding the input shaft got damaged when the torque tube was installed?

:shrug01: :shrug01: :shrug01:

navy2kcoupe

!ereH nI depparT m'I pleH

Rich, those burn marks sure do look like high spots to me. Either that or casting errors where the temp of the metal was incorrect or something. BUT, the pilot bearing/bushing is a WHOLE 'nother issue. That DON'T look good at all.....

Andy

Andy

My intention is to have all of the following replaced:

The drivetrain is already out of the car, so no sense half stepping now.

I have been conversing with RPM Transmissions and the guy I have been talking with recommended that based on what he sees in the pressure plate and flywheel, that I NOT use an organic based clutch disk. I had been planning on using a McLeod RST clutch, but I will have to now consider using the RXT instead. He said he would not recommend the Centerforce clutch at all.

- Pilot bearing (bearing this time, NOT bushing)

- Flywheel

- Clutch assembly

- Throwout bearing/slave cylinder

- Torque tube input shaft

- Both torque tube bearings

The drivetrain is already out of the car, so no sense half stepping now.

I have been conversing with RPM Transmissions and the guy I have been talking with recommended that based on what he sees in the pressure plate and flywheel, that I NOT use an organic based clutch disk. I had been planning on using a McLeod RST clutch, but I will have to now consider using the RXT instead. He said he would not recommend the Centerforce clutch at all.

Well, I'm feeling pretty confident that the pilot bushing is the cause of the drivetrain squeal. Seems to me back in 2012 when I was researching this, a lot of people were recommending using a pilot bushing instead of a pilot bearing on a C5 Corvette. Now it seems the reverse is true. :shrug01:

In any event, the burn marks in the clutch seem to indicate the Centerforce wasn't holding up as well as I thought. And I'm not really sure what brand and model I want to use right now. So I guess it is back to square one trying to figure out whose recommendation to go with. Problem is you can find good and bad reviews for every one out there it seems. Which is telling me that quality control from each of the manufacturers could use some improvement.

I sure as heck don't want to make another mistake here.

In any event, the burn marks in the clutch seem to indicate the Centerforce wasn't holding up as well as I thought. And I'm not really sure what brand and model I want to use right now. So I guess it is back to square one trying to figure out whose recommendation to go with. Problem is you can find good and bad reviews for every one out there it seems. Which is telling me that quality control from each of the manufacturers could use some improvement.

I sure as heck don't want to make another mistake here.