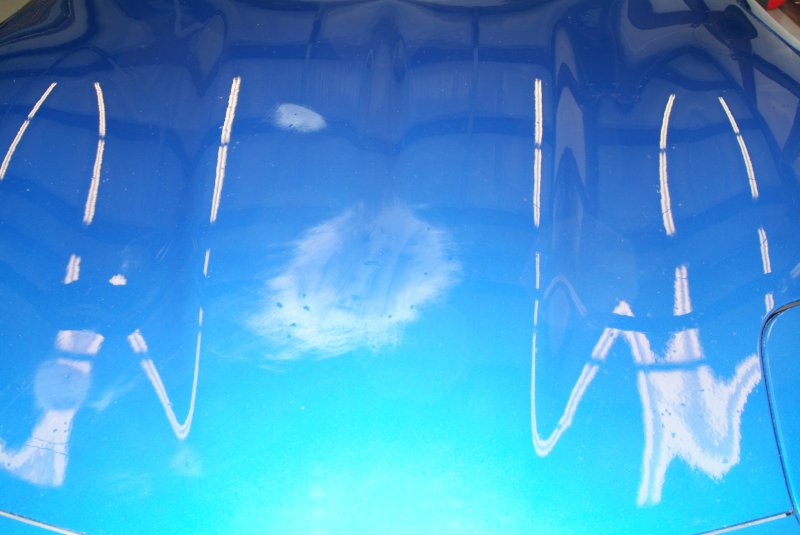

The last few days I've been working on trying to fix the paint chips on the electron blue C5Z, as it has accumulated quite a few of them in it's lifetime. I'm thinking I'm going to have to get the car repainted anyway because of the abuses inflicted upon it over the couple of years it was away from home, so this is the perfect opportunity for me to experiment and get some experience doing this kind of repair.

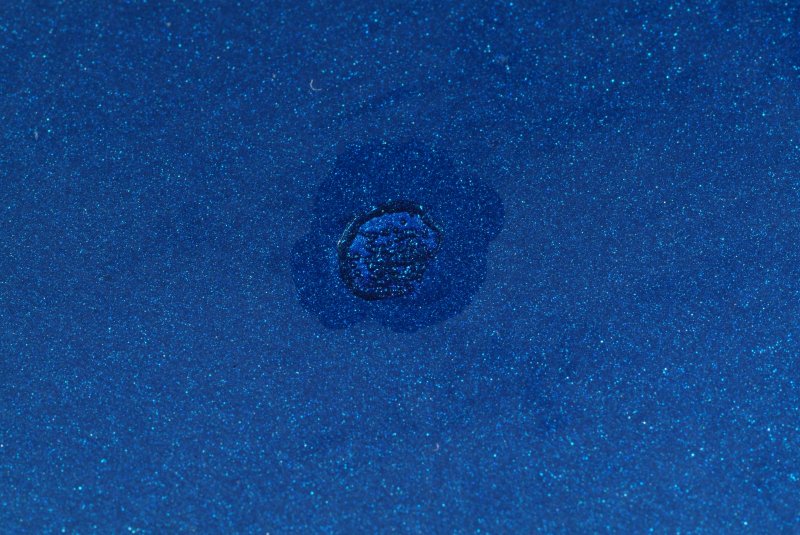

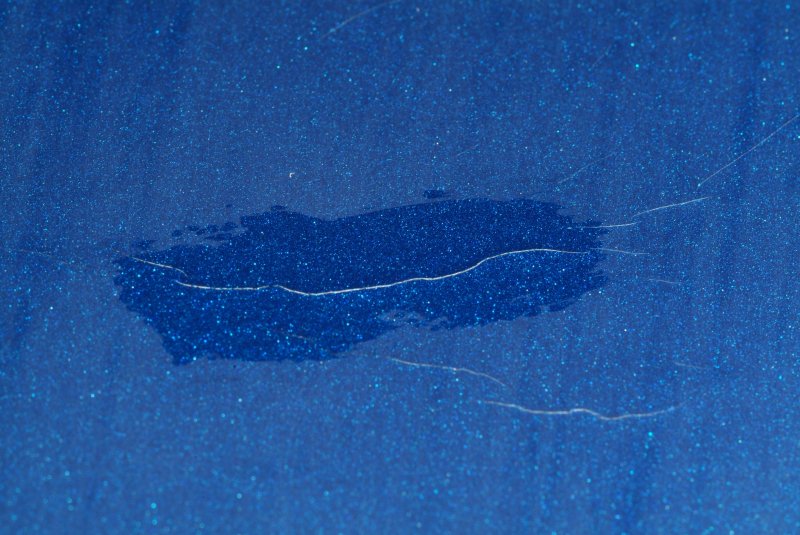

Currently I am working with the Dr. Colorchip repair system. I've got the front end of the car mostly done, but I'm going to have to go back to catch some small chips that I missed the first pass. But overall the paint job is looking a lot better as long as you don't get right up on it to take a close look. Right now instead of white colored chips in the paint, I have blue colored chips. The Dr. Colorchip product appears to be better suited to small shallow chips, as it just doesn't seem to fill in larger chips very well. So the larger the chip, the more noticeable it is, even after being colored in. So although the chips are colored to match the actual paint, there are still craters in the paint where the chips are located. They just aren't as easy to see now.

Perhaps heavier treatments with the product will fill them all in in multiple stages, but I'm thinking my strategy will be to use the Langka chip repair system (blob remover) with some touchup clearcoat. That way I can try to fill in the chip craters with the clearcoat, and use the Langka blob remover to smooth out the excess clear paint so that the craters are filled in and smoothed to match the surface around it. Theoretically, anyway. The point of doing it this way is to make sure the bottom of the chip craters are colored to match the paint, and then have the clear coat fill in so that hopefully it will leave a smoother finish that will look decent at even a close inspection.

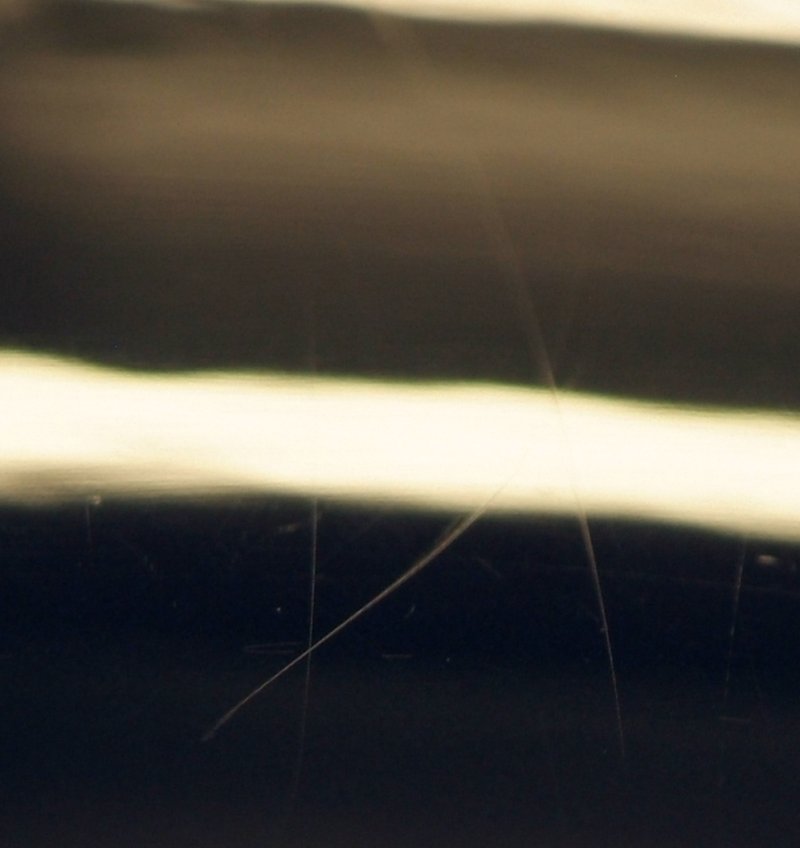

I took a small video of one section I did with the Dr. Colorchip, but didn't turn out all that well as I didn't use enough light. Therefore the video is too grainy to be as useful as I had hoped. And I should have backed off more instead of trying to get a close up shot. Oh well. I may post it later on anyway.

But I did find a video on YouTube that shows both products and somewhat how they are used that should be instructive about what I am doing myself.

I didn't try the finger in the paint method shown in the video, as I instead painstakingly used a small brush to dab at all the small rock chips individually. But I think this method might work pretty well on the fender well lips where there is a lot of road rash. I would suggest using some sort of floor covering, though, as I think this could get pretty messy dabbing the paint like that.

So, I'll just have to see how this all turns out, I guess.

Currently I am working with the Dr. Colorchip repair system. I've got the front end of the car mostly done, but I'm going to have to go back to catch some small chips that I missed the first pass. But overall the paint job is looking a lot better as long as you don't get right up on it to take a close look. Right now instead of white colored chips in the paint, I have blue colored chips. The Dr. Colorchip product appears to be better suited to small shallow chips, as it just doesn't seem to fill in larger chips very well. So the larger the chip, the more noticeable it is, even after being colored in. So although the chips are colored to match the actual paint, there are still craters in the paint where the chips are located. They just aren't as easy to see now.

Perhaps heavier treatments with the product will fill them all in in multiple stages, but I'm thinking my strategy will be to use the Langka chip repair system (blob remover) with some touchup clearcoat. That way I can try to fill in the chip craters with the clearcoat, and use the Langka blob remover to smooth out the excess clear paint so that the craters are filled in and smoothed to match the surface around it. Theoretically, anyway. The point of doing it this way is to make sure the bottom of the chip craters are colored to match the paint, and then have the clear coat fill in so that hopefully it will leave a smoother finish that will look decent at even a close inspection.

I took a small video of one section I did with the Dr. Colorchip, but didn't turn out all that well as I didn't use enough light. Therefore the video is too grainy to be as useful as I had hoped. And I should have backed off more instead of trying to get a close up shot. Oh well. I may post it later on anyway.

But I did find a video on YouTube that shows both products and somewhat how they are used that should be instructive about what I am doing myself.

I didn't try the finger in the paint method shown in the video, as I instead painstakingly used a small brush to dab at all the small rock chips individually. But I think this method might work pretty well on the fender well lips where there is a lot of road rash. I would suggest using some sort of floor covering, though, as I think this could get pretty messy dabbing the paint like that.

So, I'll just have to see how this all turns out, I guess.