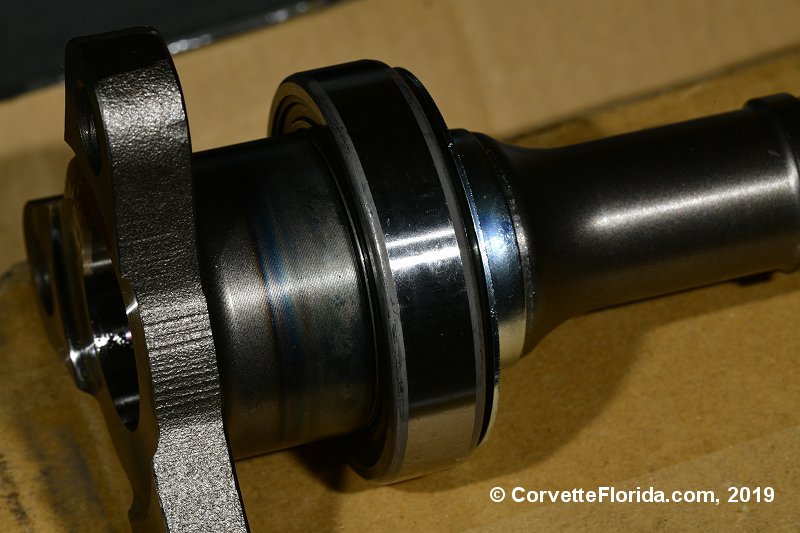

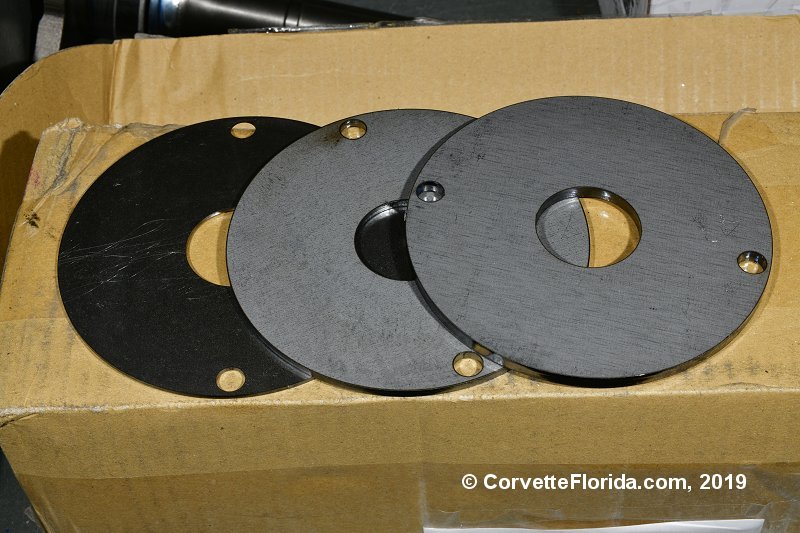

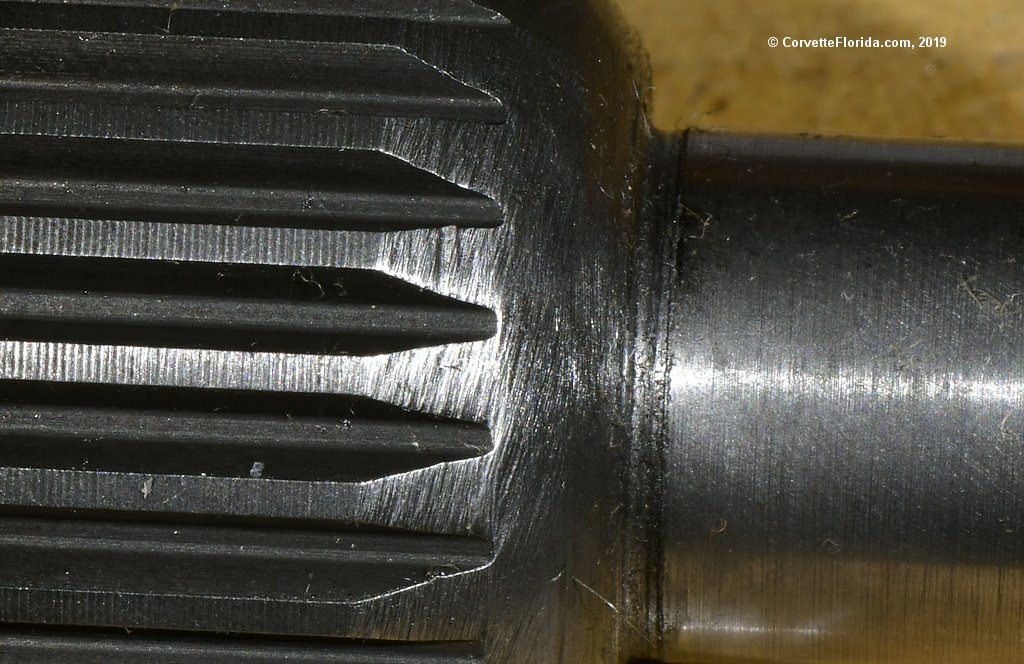

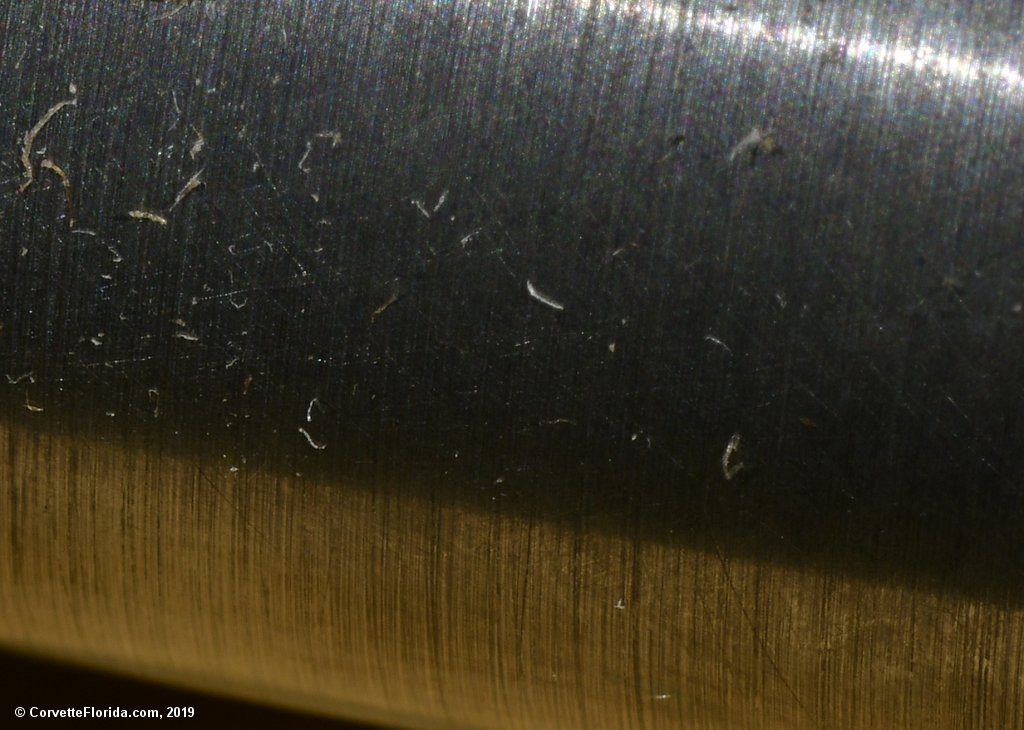

The guy I have been talking to at RPM Transmissions feels that somehow the part of the input shaft in the torque tube that rides in the pilot bushing got damaged and that damaged surface area caused the pilot bushing to become ground out and ultimately slowly failed, causing the drivetrain noise. So I believe the intermittent nature of the noise was likely from the input shaft being able to sort of flop around in the pilot bearing when the clutch pressure plate began to clamp down on the clutch disk against the flywheel. Until the clutch disk was clamped tight against the flywheel, the rotating pilot bushing would be positioned with random contact against the input shaft, making a squealing noise, depending on whether there as actually metal to metal contact. When the clutch disk became fully clamped, then the input shaft was no longer rotating inside the pilot bushing since they were then rotating at the same speed. This explains the "bearing-like" noise I have been hearing, because the noise would change in pitch as the clutch disk came up to speed before being clamped tight.

The reason this has been getting worse and worse over time is because more and more material was being ground out of the pilot bushing. And it was just a matter of luck, I guess, as to whether I would get any drivetrain noise at any given time simply because it depended on whether or not the input shaft was actually contacting the pilot bushing or not. Obviously the more slowly I let out the clutch, the more pronounced the problem could be. When I would drive more aggressively with the clutch, meaning I was letting off of the clutch pedal much more quickly, there was less time for the random position of the input shaft inside of the pilot bearing to make any noise before the clutch disk was clamped tight.

This likely explains why the noise was much more pronounced when starting to move from a dead stop than inbetween shifts while moving. The shifts while moving were much quicker than the feathering of the clutch coming off of a dead stop.

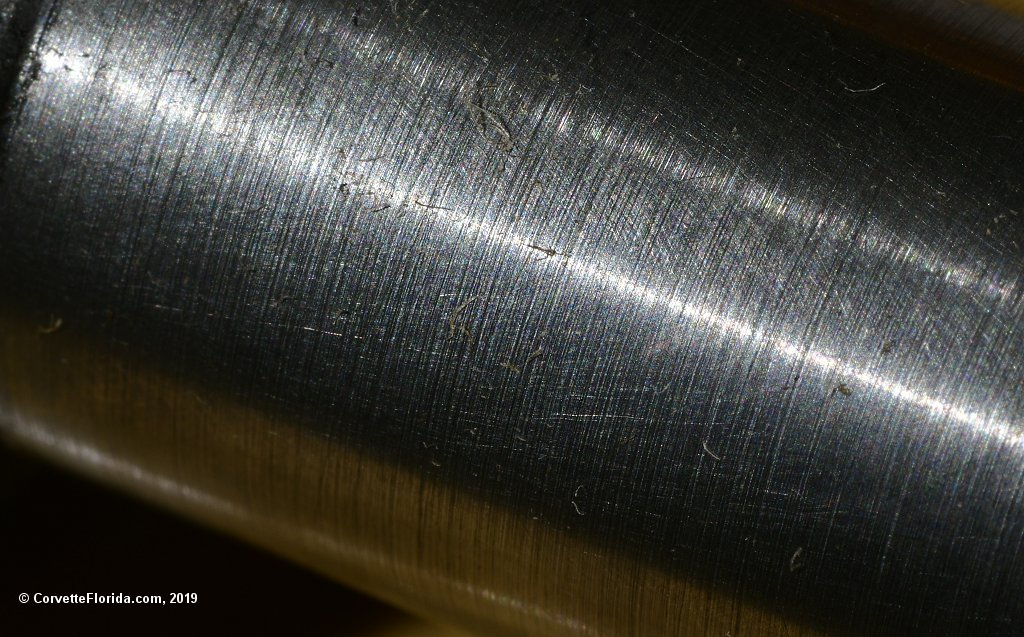

Anyway, that is my take on what I have seen of the damage, and what I am getting advice about. The one unknown at this point is if the bushing riding part of the input shaft had become damaged, that started this all off, how did that actually happen? I had preferred a brass only bushing, but I don't know if that was actually used. That brass only bushing would be far too soft to damage the steel of the input shaft, but perhaps a steel sintered pilot bushing was used, so would be hard enough to cause damage to the input shaft?

Or, looking elsewhere for the smoking gun, since this was a used torque tube put in my car back in 2012, was the input shaft already damaged then? Seems unlikely to me that the vette tech at Champion Chevrolet (now Dale Earnhardt Jr. Chevrolet) would not have noticed damage unless it was extremely subtle. The guy was pretty competent, I believe. And since he replaced the rubber bushings in the torque tube, he would have been looking at that shaft quite a bit, I would think.

Looking from another angle, perhaps those witness marks on the upper left hand quadrant of the pilot bushing are significant. Maybe the tech had a lot of trouble getting the input shaft of the torque tube into the pilot bushing. And perhaps he tried to be more forceful than usual, which seems possibly looking at those marks. As such, did that bearing riding surface of the input shaft get damaged during this install procedure? :shrug01: Honestly, this also seems unlikely, since an alignment tool is used to line up the clutch disk with the pilot bearing/bushing, so that should have been done before the torque tube was even attempted to be installed. Surely the tech couldn't have forgotten that step?

I guess I'll probably never know. But at least at this point I'm feeling pretty confident that we are looking at the smoking gun (just not seeing whose finger was on the trigger), and this can be fixed.

Finally.

Assuming I can find a new clutch that won't have it's own noise problems, which it seems that a lot of them tend to have, more or less.

Right now the leading candidates for consideration are:

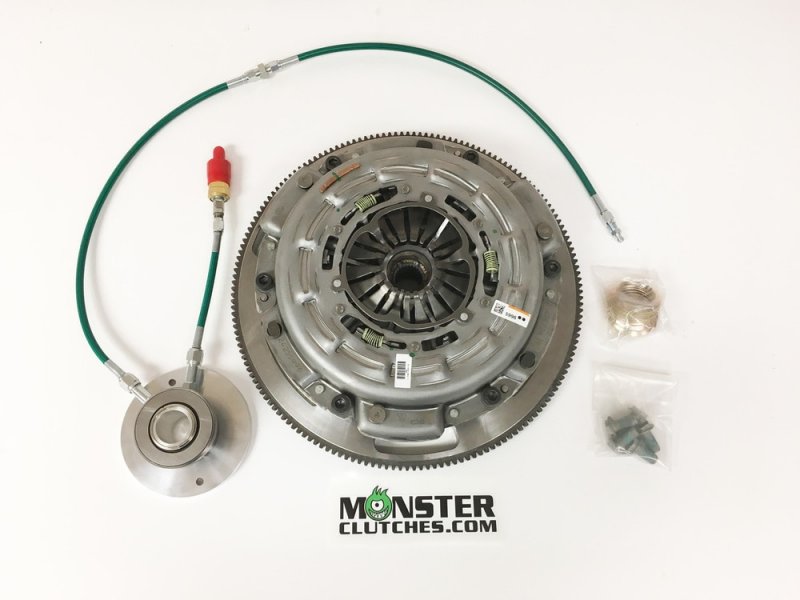

But I am still doing research. I did look into the Monster triple clutch disk, but when I asked RPM Transmission about it, the guy seemed adamant that this would not be a good idea for me. He said that the extra mass of the triple clutch disks could be hard on the synchronizers in the transmission. I believe these guys would know about such things.

I just know I need to make a decision SOON, because my car can't be up on that lift at the shop forever.

Lordy, wouldn't it be NICE to finally have all the problems ironed out in this car? :dancer01:

The reason this has been getting worse and worse over time is because more and more material was being ground out of the pilot bushing. And it was just a matter of luck, I guess, as to whether I would get any drivetrain noise at any given time simply because it depended on whether or not the input shaft was actually contacting the pilot bushing or not. Obviously the more slowly I let out the clutch, the more pronounced the problem could be. When I would drive more aggressively with the clutch, meaning I was letting off of the clutch pedal much more quickly, there was less time for the random position of the input shaft inside of the pilot bearing to make any noise before the clutch disk was clamped tight.

This likely explains why the noise was much more pronounced when starting to move from a dead stop than inbetween shifts while moving. The shifts while moving were much quicker than the feathering of the clutch coming off of a dead stop.

Anyway, that is my take on what I have seen of the damage, and what I am getting advice about. The one unknown at this point is if the bushing riding part of the input shaft had become damaged, that started this all off, how did that actually happen? I had preferred a brass only bushing, but I don't know if that was actually used. That brass only bushing would be far too soft to damage the steel of the input shaft, but perhaps a steel sintered pilot bushing was used, so would be hard enough to cause damage to the input shaft?

Or, looking elsewhere for the smoking gun, since this was a used torque tube put in my car back in 2012, was the input shaft already damaged then? Seems unlikely to me that the vette tech at Champion Chevrolet (now Dale Earnhardt Jr. Chevrolet) would not have noticed damage unless it was extremely subtle. The guy was pretty competent, I believe. And since he replaced the rubber bushings in the torque tube, he would have been looking at that shaft quite a bit, I would think.

Looking from another angle, perhaps those witness marks on the upper left hand quadrant of the pilot bushing are significant. Maybe the tech had a lot of trouble getting the input shaft of the torque tube into the pilot bushing. And perhaps he tried to be more forceful than usual, which seems possibly looking at those marks. As such, did that bearing riding surface of the input shaft get damaged during this install procedure? :shrug01: Honestly, this also seems unlikely, since an alignment tool is used to line up the clutch disk with the pilot bearing/bushing, so that should have been done before the torque tube was even attempted to be installed. Surely the tech couldn't have forgotten that step?

I guess I'll probably never know. But at least at this point I'm feeling pretty confident that we are looking at the smoking gun (just not seeing whose finger was on the trigger), and this can be fixed.

Finally.

Assuming I can find a new clutch that won't have it's own noise problems, which it seems that a lot of them tend to have, more or less.

Right now the leading candidates for consideration are:

- Monster LT1-SC twin disk

- McLeod RXT twin disk

But I am still doing research. I did look into the Monster triple clutch disk, but when I asked RPM Transmission about it, the guy seemed adamant that this would not be a good idea for me. He said that the extra mass of the triple clutch disks could be hard on the synchronizers in the transmission. I believe these guys would know about such things.

I just know I need to make a decision SOON, because my car can't be up on that lift at the shop forever.

Lordy, wouldn't it be NICE to finally have all the problems ironed out in this car? :dancer01: