|

| Maintenance, Mods, & Tips Mods | Tips | Repairs & Troubleshooting |

|

|

04-25-2012, 09:06 PM

04-25-2012, 09:06 PM

|

#1521

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,125

Name : Rich Zuchowski

|

Quote:

Originally Posted by Benjamin

have you thought about flying Ed down and then letting him dyno tune @ a dyno location local? would be logistically easier than shipping a car up there....

|

That might be workable if I knew of someone local with a dyno we could use. The problem is that I don't know of anyone nearby with a dyno that I would be comfortable going to.

__________________

|

|

|

04-25-2012, 09:39 PM

04-25-2012, 09:39 PM

|

#1522

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,125

Name : Rich Zuchowski

|

Anyway, today I put the wastegates back together again and cleaned out the vent ports. The port on my original wastegate just seemed like compacted sand. The newer one seemed to be filled with a putty like substance. Both cleaned out nicely, though, so they are now good to go.

You wouldn't think that a 10 pound spring would be tough to compress. But I'll tell you, trying to compress that spring between the two halves of the wastegate and get those little 4mm screws lined up trying to hold the wastegate together with one hand and trying to put the screws in with the other just about did me in. After dropping the dang screws way too many times, I had to tie the two halves of the wastegates together with wire ties and gradually pull the them together until I could get two screws started. Perhaps it would have been easier with the wastegates off of the car.  But then I would have had to find gaskets for the joints. But anyway, got 'er done.

I started working on mounting the wiring harness for the fuel pumps back at the fuel tank end and I've got about 7 feet too much cable. Got the ground wire mounted on the bolt that holds the fuel filter, and mounted the two relays back there onto the bolt that holds a fixed hose bracket right in front of the fuel filter. I hope those relays can stand the elements because they will most certainly get wet if I drive the car in wet weather. Anyway, I just bundled up the excess cable as best I could and tied it up above the fuel filter. Maybe later on when all the more pressing headaches are out of the way I'll pull it back down and shorten it to fit properly.

I ordered a tool that I think will allow me to rivet threaded nuts into the firewall, but O'Reillys website had the description wrong and all I got was the tool, and it did not come with the threaded nuts like it was supposed to. So I've got to work this out now. I swear, I wish I could just order everything I need from Summit Racing. Those guys just don't seem to make mistakes as far as I have seen.

Oh yeah, still waiting on that throttle body. The guy says it is being shipped out today, but I'm not holding my breath. He's not been real accurate with past predictions about when I would be getting it.

__________________

|

|

|

04-26-2012, 11:44 AM

04-26-2012, 11:44 AM

|

#1523

|

|

Sinister C4

Join Date: Jan 2007

Location: Largo, FL

Posts: 1,223

Name : Eric G

|

So is the throttle body the last part you are waiting on? You get the fuel pumps installed and the fuel rail back together? With all the wastegate vent stuff, I've lost track! Feel like giving us a run down on what's left to do?

|

|

|

04-26-2012, 12:12 PM

04-26-2012, 12:12 PM

|

#1524

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,125

Name : Rich Zuchowski

|

The fuel pump is in the tank. I'm still playing around with getting the wiring harness run. I don't like the idea of just using sheet metal screws to mount the fuse blocks in the battery compartment for the pumps so I'm going to try to use threaded nut pop rivets to mount a permanent threaded nut in the firewall. I ordered the tool from OReily's Auto, but in spite of the fact that their website said it came with threaded nuts, when I got it, they were NOT included. So that really didn't help much. They are going to take care of this tomorrow when I run the tool up to a local store to exchange it.

No, don't have the fuel rails back on. I might do that today. Was really waiting to get the throttle body back first, but I'll just leave off that cross over hose in the front so it won't be in the way.

Need to put some gasoline in the gas tank to check for leaks at the pump mounting seal.

Need to adjust the new fuel pressure regulator when I have the fuel system all back together again.

Need to buy a new battery and hook up the battery terminals for the new fuel pump system.

When I can start the car, I need to check for fuel leaks again and make sure everything is OK.

If everything checks out, I then need to pull off the passenger side fuel rail and disconnect the wiring connector going to the MAP sensor. Then need to pull off the vacuum hose at the front of the intake manifold that goes to the blow off valve and relocate that hose to the vacuum block I installed. Then install the 2 bar MAP sensor where that hose came out of the intake and put in the wiring harness extension for it.

When the tune calls for it, I need to run a vacuum hose from the fuel pressure regulator to the vacuum block so the regulator will then be vacuum regulated.

Need to hook up with wideband sensor to interface with HPTuners and make sure I know what the heck I am doing with it.

Time to get to the nitty gritty with the tuning. I have no idea what to expect, but I suppose I'll have to take the car out often to do data acquisition to send to Ed to try to dial in the tune. I'm hoping we won't need a dyno. There are some long stretches of flat road around here where I can hopefully do some steady state data collection. But no matter what, I suppose that sometime I am going to have to put it on a dyno. But I'll cross that bridge when I get to it.

Anyway, I think that covers about everything. Well, I need to break in the new brake pads and rotors, and there is that oil level sensor that is leaking that I need to replace the next time I change the oil. Probably some other minor stuff that I just can't recall now. Just praying for no smoke and flames all along the way.

__________________

|

|

|

04-27-2012, 12:27 AM

04-27-2012, 12:27 AM

|

#1525

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,125

Name : Rich Zuchowski

|

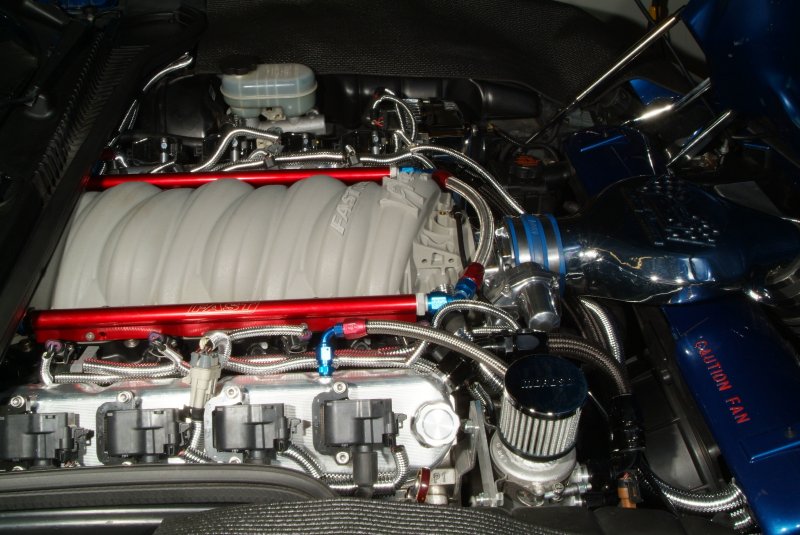

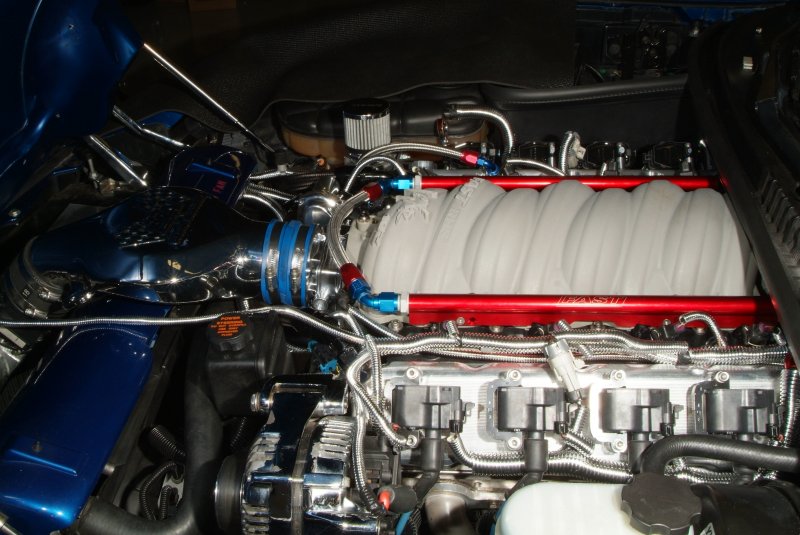

Got the fuel injectors and fuel rails put back onto the engine today. That banjo fitting at the back of the driver side fuel rail seems to clear that rubber plug I put into the fire wall just fine.

Also just tidied up some of the wiring on the engine a bit. I'm pretty much going to take off all of the black convoluted tubing around the engine, as I've seen too many instances of melted plastic here and there with that stuff. It's supposed to have a max temp rating of only about 200 degrees, and quite frankly that's just not good enough close to the engine when the cooland itself can easily reach over that limit. So I'm going to use as much of the Taylor high temp stuff as I can. That stuff is rated at around 1,000 degrees, so I feel a lot more comfortable using it. You can see a little bit of it in the pics above.

Oh yeah, I remembered something else I need to do. While my car was at Aaron's, I asked him to fix the loose right front fender that had gotten broken at the rear tab at Harwood's shop. Well, he did, but I just think I need to do a little bit better job at that "fix", I guess.

__________________

|

|

|

04-28-2012, 12:13 AM

04-28-2012, 12:13 AM

|

#1526

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,125

Name : Rich Zuchowski

|

Got the new throttle body in today. Looks pretty sharp.

I figure I'll put that in tomorrow as I had some other things to do today.

Got that pop nut rivet tool thing straightened out, so since I have never used one before, I played around with it a bit to get used to it before using it on the firewall of my car. I found that the tool just doesn't give my feeble hands enough leverage to work with the M6 nuts, so I have to work with the M5 and below. But this looks like a real handy tool to use to put a threaded insert into a blind panel where you can't reach the other side to put a nut on a bolt.

__________________

|

|

|

04-28-2012, 06:41 PM

04-28-2012, 06:41 PM

|

#1527

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,125

Name : Rich Zuchowski

|

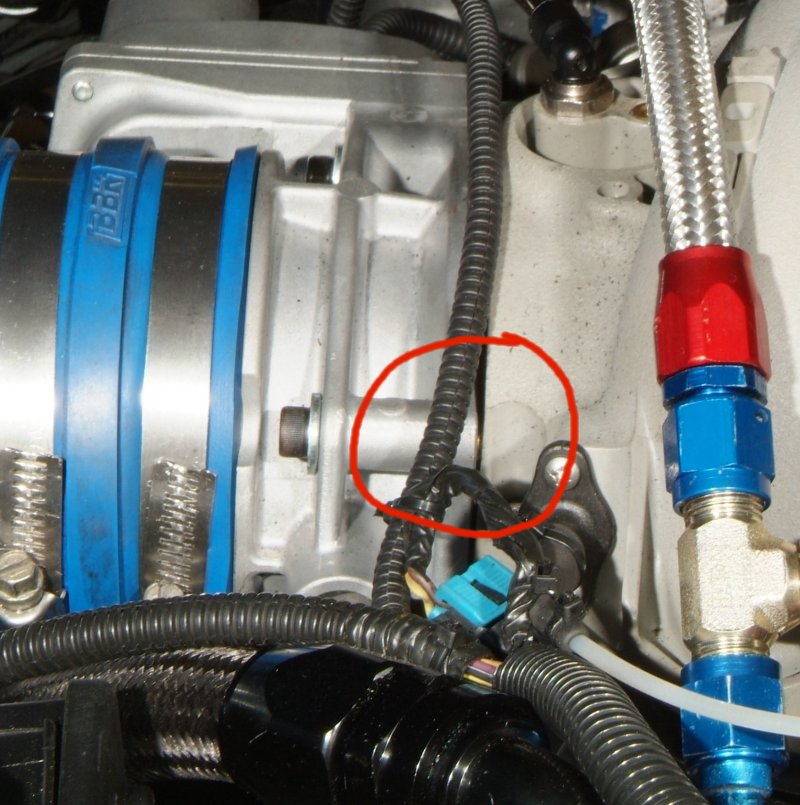

Put the LS2 throttle body on today. Also put some more insulating tubing on some wiring and untangled some messes. Need to still lay out the wires and wrap them up to make them neater now, though.

Noticed a couple of things that are unsettling, though.

First off, apparently Aaron drilled a hole through the throttle body blade on the one that he installed on my car. I hope the guy I am sending it back as a core doesn't kick it back as being unacceptable this way.

I also noticed that there was a bit of oil at the bottom of the old throttle body when I pulled it off of the intake manifold. So thinking about the warning about fluids in the intercooler, and recalling that Aaron had had at least three instances that I am aware of where oil had gotten into the intake of the turbo plumbing, I decided to pull off the blow off valve to take a look into the bottom of the intercooler. Fortunately everything looked OK in there, with just a light film of gunk, but I found that the o-ring seal for the blow off valve was broken.

Great......

Then to top all of this off, I noticed that the throttle body isn't fitting flush against the front of the intake manifold. The mounting flange for this LS2 throttle body doesn't seem to be as wide as the LS3/LS7 throttle body I took off, and since it isn't fitting flush I could see the throttle body seal peaking out from behind the throttle body. I checked some older pics, and evidently this gap was there when I got the car back home, but it just wasn't noticeable since the orange o-ring wasn't visible. I hope this darn thing is sealing properly. Otherwise I don't have any idea what I would need to do about it. BTW, it appears that the brass mount in the FAST intake that the throttle body bolts to is sticking out a bit, which is making that gap I see.

One step forward and two steps back.......

Now I've got to find a blowoff valve o-ring and wait for that to show up. Then be on pins and needles hoping that throttle body is sealed to the intake manifold.

__________________

Last edited by Rich Z; 04-28-2012 at 07:21 PM.

|

|

|

04-29-2012, 02:57 AM

04-29-2012, 02:57 AM

|

#1528

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,125

Name : Rich Zuchowski

|

Yeah, taking a lot of pics of my car and engine sure has proven worthwhile when I find something to question at a later date. That gap between the throttle body and FAST intake was there when I got the car home from Aaron's. This pic was taken on 12-14-2011 which plainly shows it.

Which can be both good news and bad news, I guess.

The bad news is that the brass insert is definitely further out than it should be for the TB to mount flush with the front of the intake. From what I can tell looking at the pics of the intake manifold before it was installed on the engine at Harwood's, that insert was pretty close to being flush in the manifold.

The good news is that when I tested the engine for vacuum leaks with a can of carburetor cleaner, I know I sprayed right at the throttle body and manifold junction because I thought that was the most likely place a vacuum leak would be, if anywhere, and there were NONE detected. So maybe the throttle body is still sealing OK even with that gap.

The following pics were taken on 01-22-2010 at Harwood's shop before the manifold was installed and any throttle body mounted on it, showing that brass fitting and how much more relatively flush it was at that time.

Unfortunately I don't think I have any other pics of the exact angle I need of this gap between the throttle body and manifold to be able to pinpoint how, when, or where this problem first started showing up.

__________________

|

|

|

04-29-2012, 08:25 AM

04-29-2012, 08:25 AM

|

#1529

|

|

Island in the Caribbean.

Join Date: Apr 2007

Location: Sarasota, FL

Posts: 432

Name : Timothy Halley

|

That happens when the screws are too long and it bottoms out too early, so it pulls the Brass Nuts out.

You need shorter screws or more washers, either way, tap the Brass Nuts back into the Fast Manifold and reattach the Throttle Body back on.

__________________

Tim's Toys

-----

|

|

|

04-29-2012, 10:36 AM

04-29-2012, 10:36 AM

|

#1530

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,125

Name : Rich Zuchowski

|

Quote:

Originally Posted by Curacao

That happens when the screws are too long and it bottoms out too early, so it pulls the Brass Nuts out.

You need shorter screws or more washers, either way, tap the Brass Nuts back into the Fast Manifold and reattach the Throttle Body back on.

|

So those brass threaded nuts aren't threaded into the intake manifold? Just pressed in?

__________________

|

|

|

|

Currently Active Users Viewing This Thread: 1918 (0 members and 1918 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -4. The time now is 05:41 AM.

|