Was over in the garage today just puttering around with the car, cleaning up stuff and looking for more wires hanging too close to the headers to try to wrap them up to keep the heat from affecting them.

Found a few more issues that need to be noted....

Here's another part of that plastic shield behind the left from fender that got broken, apparently from Aaron tugging on the fender to get the PCM out for Jim to program on the workbench. With all this breakage that took place, I sure wish they had just done the tuning through the OBD port

Next I noticed that one of the two screws to the right of the TAC module on the PCM had not been put into place.

Looking further, I found that the single screw to the right of the TAC module was missing as well, so that module was pretty much just flapping around on the PCM. I couldn't get a pic of the actual screw, but the arrow shows where it is located.

Seems to me that the wiring in there is pretty much a mess as well. Sure wish Aaron had cleaned up that bird's nest when he was done in there.

Next I found one of the bolts holding the STS scavenge pump onto the frame was missing.

Now, with the hub out of the knuckle, I was able to get a much better shot of that damaged wheel speed sensor that was on the left rear wheel.

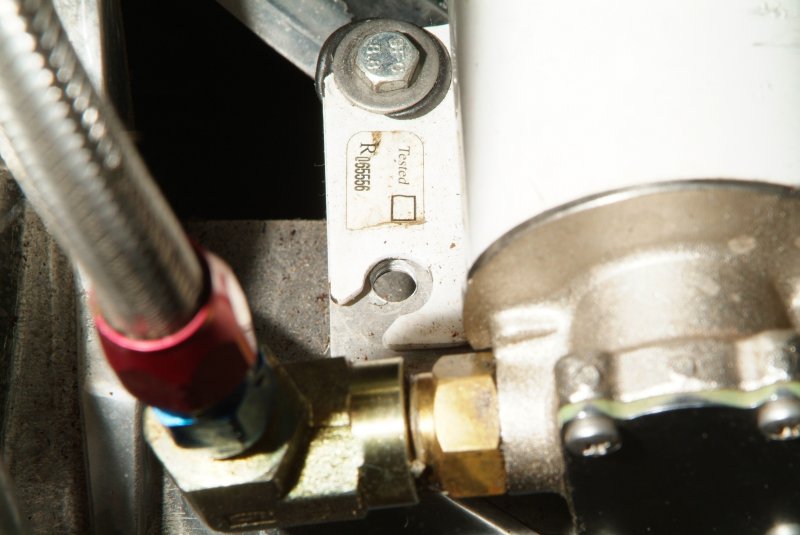

Lastly (for now, anyway), can anyone tell me what this doohicky near the starter is and how I can go about tightening it to fix that oil leak? Does that cable end come out, and if so, how? It looks like the thing is only made of plastic, so I don't want to try to shoehorn a wrench into there to try to tighten it. With that connector out, I may have a socket that would work on it.