Well, I think I've been looking at this from the wrong perspective concerning what caused the driveshaft to push through the torque tube. Maybe it didn't get pushed through at all. After all, what could actually do that? The transmission and differential? HOW? They are restrained by being bolted to the rear cradle which is bolted to the frame of the car. So I would have to say, no, not likely.

But suppose the shaft were PULLED forward? Now what could cause that?

Well let's look at the facts that have been found so far.

There were two bolts missing on the left side of the bell housing, and a third one on that same side there that I found sticking out a quarter of an inch. So there really was nothing at all holding the bell housing to the block on that side. Why is the bell housing bolted down in the first place? To keep it from moving. So with the bolts missing or loose on one side of the bell housing, what could happen? Well, it could MOVE. At least on the driver's side. Think about what happens when your rear tires break loose when you get on it. The rear end slides right, which means the torque would tend to want to move the drivetrain to the right. Why are there three bolts on the left side (driver's side) and only two on the right side? Quite likely because that is where the extra holding power of the extra bolt is needed. Without those bolts being there, what would happen? Yeah, that side of the bell housing would flex off of the block.

So what would happen if the bell housing COULD move? Well so could the front of the torque tube and driveshaft. But what would happen then? Well, the input shaft of the driveshaft slides into the pilot bearing in the crank. It also rides through both of the clutch disks which are turned by the splines in the center of those disks that mate with the splines of the input shaft going through them.

Here's a pic of one of the clutch disks showing those splines and how they should appear.

Notice the nice flat undamaged mating surfaces in the splines that would mate with the splines of the input shaft going through it.

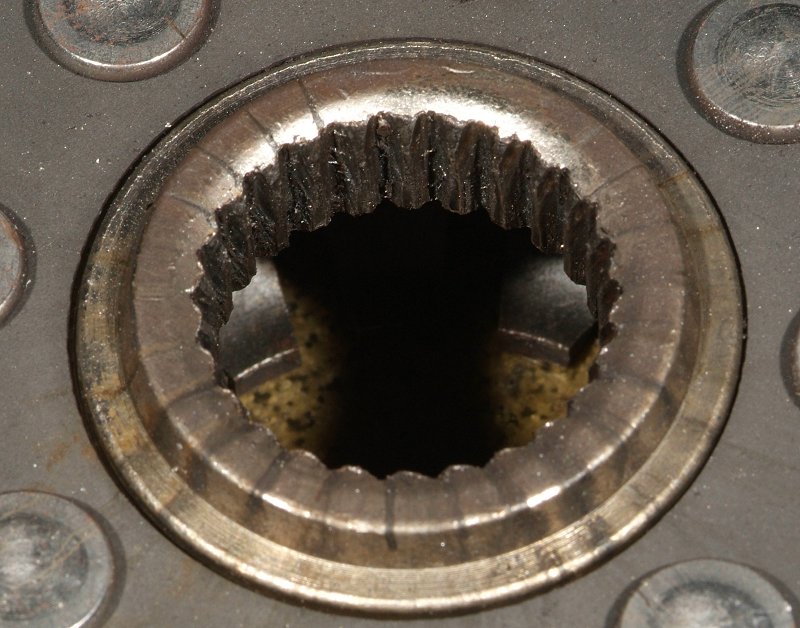

But look at the splines on this clutch disk.

Notice the diagonal cuts across the splines. There is ONLY one thing that could do that, and that would have to be the splines on the input shaft going through the disk making those cuts. Which would have to mean that somehow that clutch disk was not perpendicular to the input shaft, so the input shaft's splines cut INTO the matching splines in the clutch disk.

Furthermore, I would speculate to say that there is a damned good chance that the disk got JAMMED onto that input shaft. And if that happened, what would be the result? Well, when releasing the clutch to close the pressure plate upon the disks, what would happen? If that disk were jammed on tight enough, it would PULL on the input shaft towards the flywheel. How much force is a clutch pressure plate exerting now on the driveshaft trying to pull it forward? Probably more than whatever it is in the torque tube that is designed to keep the drive shaft from moving forward was designed to handle.

So what happened when the drive shaft got pulled forward enough to drop the input shaft bearing out of the front of the torque tube? Well, there would likely have been movement of the shaft inside of the throwout bearing/slave cylinder. And it appears that there are scuff marks and some minor damage there. Perhaps this contributed to the slave cylinder finally failing completely.

Shane mentioned to me that he had to use a very large pry bar and nearly bend it out of shape to get the torque tube separated from the bell housing. My guess is that the clutch disk was jammed solidly onto the input shaft of the drive shaft then.

What about the pilot bearing itself if the drive shaft was going at an angle and moving in and out of the bearing? Well, does it look like the shaft remained at one place in the bearing in this picture?

I believe I see multiple areas where the shaft was seating into the pilot bearing which indicates that the shaft did not remain at the same depth within that bearing.

So, that's my speculation about the probable smoking gun in all this. My opinion is that the missing and loose bolts on the bell housing actually caused all of the damage now seen in the drive train. The clutch disk shows clear evidence that the splines in it were not lined up to mate to the input shaft splines, showing obvious damage as a result. It shows that the shaft had clearly cut into those disk splines at an angle. There really isn't anything I can see that could press against the back of the driveshaft to PUSH it through the torque tube. If the driveshaft was too long, then how did it get seated into the torque tube in the first place? I watched Chris Harwood install that carbon fiber drive shaft into the torque tube, and no way he used any sort of exceptional force to do so. Just a couple of light raps with the handle of a dead blow mallet and that was enough. So this seems to rule out PUSHING against the driveshaft, which only leaves PULLING on it from the front. And what is the only thing that could do that? The clutch pressure plate via the clutch disks.

There is still some gray area, of course. Was that loose bolt gradually loosening up on the bell housing while the car was being driven, and the damage started taking place at a certain point until it had a sudden complete failure? Did the slave cylinder fail coincidentally or was it sustaining damage that caused it to fail? What is it exactly that holds the driveshaft from moving forward in the torque tube and how much force does it take to BREAK that function? As far as I can figure out, the clutch is the only thing that has enough power to do that, and the only way it could do that is by PULLING on the shaft via a jammed clutch disk on the shaft. But was the disk intermittently jamming on the input shaft or has it been jammed on there for a while? I'm thinking it had to be happening intermittently making the noises I heard intermittently. But it could have been jammed on, but only sometimes became cocked at an angle enough to make noise. Probably no way to know for certain.

That might also explain the weirdness of the clutch action I experienced. When I would slowly release the clutch pedal, I could feel something grab ever so slightly and the car would start slowly moving. Releasing the clutch further did not increase the grab until nearly at the top of pedal travel, where it would finally grab completely.

Certainly all guess work based on the evidence I can actually see. Any maybe right or maybe wrong. But so far, it's the only thing that actually FITS the evidence with my limited knowledge of everything involved.

Sheesh, but do I have a splitting headache now. I just might have to break into my remaining dwindling supply of Excedrin Migraine pills..