|

| Maintenance, Mods, & Tips Mods | Tips | Repairs & Troubleshooting |

|

|

02-07-2012, 12:38 PM

02-07-2012, 12:38 PM

|

#1351

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,127

Name : Rich Zuchowski

|

Quote:

Originally Posted by CorvetteJohn

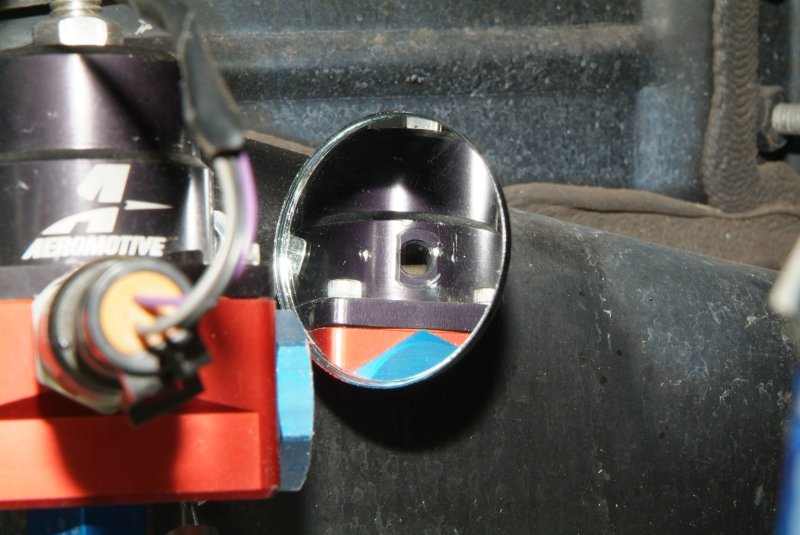

That picture of the fuel rail plug looks to me like when the engine torques up it is scaping the firewall. At least in this pictures I see two witness marks. I wonder if you could use a banjo fitting to get some clearance and also to have a return line from the back of that fuel rail. It would only need to be abel to move the fuel back to the return line so it would not have to be very large in id.

|

Right now I'm just looking for ANYTHING that will work. Do you know of any banjo style fitting that would work? I've been pouring over pages and pages of fittings from various websites and just haven't seen anything that looks promising yet.

One of the guys helping me out on CorvetteForum suggested that the current plumbing layout will work OK (not optimal, but just OK), so it wouldn't kill me (nor the engine) to keep it as it is. He didn't comment on the size of the plumbing, but I am planning on going to AN-08 all the way to the regulator, regardless. He did mention that "crud" possibly could accumulate at that "dead head" end of the fuel rail, so I'm trying to figure out the best fuel filtration that I can put in place to keep that "crud" from even getting to the fuel rails.

As for the scraping against the firewall, I presume that happened either at Chris's or Aaron's (or possibly both) when they removed the fuel rail for troubleshooting purposes. The motor mounts are Pfadt polyurethane, so I don't think the engine moves very much at all under torque.

__________________

|

|

|

02-07-2012, 12:41 PM

02-07-2012, 12:41 PM

|

#1352

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,127

Name : Rich Zuchowski

|

Quote:

Originally Posted by gmjunkie

The nipple that looks like it had been screwed in too tight in that hole!

That used to be a threaded hole,Now the treads have been ripped out!

I don't know how much volume the stock pumps deliver,But I'll look see if it's in the service manual! |

Ah, OK. I was told on CorvetteForum that it isn't necessary (nor advised) to use that fitting anyway. The purpose of it is to adjust the fuel flow based on the vacuum line coming from the intake. But since the PCM expects a constant fuel pressure for it's A/F calculations, than having a variable fuel pressure from the regulator would actually CAUSE problems with the tuning of the engine. So it actually is best that it is not being used. Personally, I would like to see that hole just plugged off, rather than being open to the elements, so I may have to see if I can find a set screw or something to plug it off.

Thanks...

__________________

|

|

|

02-07-2012, 12:50 PM

02-07-2012, 12:50 PM

|

#1353

|

|

Corvette,GM Classic Freak

Join Date: May 2007

Location: Vero Beach FL/Old Fort NC

Posts: 1,052

Name : I'm Not Post'n in BOI

|

Quote:

Originally Posted by Rich Z

Ah, OK. I was told on CorvetteForum that it isn't necessary (nor advised) to use that fitting anyway. The purpose of it is to adjust the fuel flow based on the vacuum line coming from the intake. But since the PCM expects a constant fuel pressure for it's A/F calculations, than having a variable fuel pressure from the regulator would actually CAUSE problems with the tuning of the engine. So it actually is best that it is not being used. Personally, I would like to see that hole just plugged off, rather than being open to the elements, so I may have to see if I can find a set screw or something to plug it off.

Thanks...

|

I guess if you want it running rich at idle and washing down the cylinder walls it would be alright!

__________________

junk!!

|

|

|

02-07-2012, 04:32 PM

02-07-2012, 04:32 PM

|

#1354

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,127

Name : Rich Zuchowski

|

Quote:

Originally Posted by gmjunkie

I guess if you want it running rich at idle and washing down the cylinder walls it would be alright!  |

Explain, please....

__________________

|

|

|

02-07-2012, 04:38 PM

02-07-2012, 04:38 PM

|

#1355

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,127

Name : Rich Zuchowski

|

I got the passenger side wheel, brakes, etc. all together with the new half shaft and started taking apart the driver's side. I bought a GM tool to break the shaft loose from the hub and that, along with my spraying the shaft and hub with PB Blaster for the last couple of weeks, got the shaft loose with no issues. I'll get it all apart tomorrow and start cleaning up the various stuff before putting it back together again with the new shaft. Hopefully my rear brakes will still work....

Been talking with a guy from NastyPerformance.com about the fuel system and he's going to be working with me to try to get that all worked out. BTW, he recommended a different fuel pressure regulator, saying that the Aeromotive has been known to be flaky trying to keep a stable fuel pressure.

But in any event, the light at the end of the tunnel is starting to get brighter....

__________________

|

|

|

02-07-2012, 04:43 PM

02-07-2012, 04:43 PM

|

#1356

|

|

www.revxtreme.com

Join Date: Apr 2006

Location: Bradenton

Posts: 1,171

Name : Tracy Lewis

|

Quote:

Originally Posted by Rich Z

Ah, OK. I was told on CorvetteForum that it isn't necessary (nor advised) to use that fitting anyway. The purpose of it is to adjust the fuel flow based on the vacuum line coming from the intake. But since the PCM expects a constant fuel pressure for it's A/F calculations, than having a variable fuel pressure from the regulator would actually CAUSE problems with the tuning of the engine. So it actually is best that it is not being used. Personally, I would like to see that hole just plugged off, rather than being open to the elements, so I may have to see if I can find a set screw or something to plug it off.

Thanks...

|

Absolutely false....but I'm sure I know nothing as I see some other problems you have decided to ignore also. I'm not sure why you keep getting charmed by those that have only some knowledge or wrong info alltogether, but hey, its your car!

__________________

Tech Support for most anything.

|

|

|

02-07-2012, 06:13 PM

02-07-2012, 06:13 PM

|

#1357

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,127

Name : Rich Zuchowski

|

Quote:

Originally Posted by RevXtreme 1

Absolutely false....but I'm sure I know nothing as I see some other problems you have decided to ignore also. I'm not sure why you keep getting charmed by those that have only some knowledge or wrong info alltogether, but hey, its your car!  |

Well, explain it to me, then, please.

Perhaps my understanding is faulty, but from what I understand the PCM controls the air/fuel ratio at all RPM ranges by controlling the pulse width of the fuel injectors. This pulse width command to the fuel injectors has to assume that the fuel pressure is known, as the amount of fuel needed for a proper air/fuel mixture is ONLY controlled by the duration of time that the fuel injector is commanded to be open. In other words, with a constant 60psi of fuel from the regulated fuel rails to the fuel injectors, if the PCM has been sending out a 20 millisecond pulse to the fuel injector and decides it needs MORE fuel for a proper AFR, it issues a longer firing pulse (like 22 ms). If it needs LESS fuel for a proper AFR, it issues a shorter pulse (like 18 ms). These calculations all HAVE to assume a known and constant fuel pressure, otherwise the desired AFR will be completely at the mercy of whatever the fuel pressure is at any given firing of the fuel injector pulse. A 22 ms at 60 psi will not deliver the same amount of fuel as an 22 ms pulse at 58 psi. So if the PCM commands say an 18 ms pulse because less fuel is warranted for the AFR desired, and the fuel pressure has changed from 60 psi to 62 psi for that commanded 18 ms pulse, will the resulting AFR be what the PCM was trying to achieve?

So with the fuel pressure regulator changing the pressure in the fuel rails via that vacuum line, how does the PCM know what the fuel pressure actually is at any given moment? Is there a fuel pressure sensor somewhere that the PCM references for this variable in it's calculations for the proper AFR to command for each injector firing? I've been looking, and I just don't see one. Not to say that there isn't one that I just haven't found yet, mind you.

What that vacuum line does for the fuel pressure regulator (as far as I have been able to determine) is to reduce fuel pressure at high vacuum, which indicates low engine speed, such as idle. Then on the reverse side, say in a boost condition with positive manifold pressure, the regulator will increase the fuel pressure on a 1:1 ratio.

So with all the above in mind, how does the PCM know how to accurately command the AFR that it calculates as being optimum when the CONSTANT it expects from the actual fuel pressure varies with what the fuel pressure regulator is doing with fuel pressure?

I hope this doesn't come across as argumentative, as I am trying to filter everything anyone suggests to me by everything else I am told and what I am learning from every possible source I can find in this process. I just am not taking ANYONE or ANYTHING at face value any longer without researching what I am being told to do. If I understand something incorrectly, then please SHOW me where I am wrong about what I think I know. Sorry, but I'm just not buying ANYONE telling me to "Do it this way, trust me". I've already trusted two shops far more than I should have, and look where that has gotten me...

So, if the PCM can, in fact, determine actual fuel pressure somehow, then yes, I will buy the fact that a fluctuating fuel pressure from the fuel pressure regulator via that vacuum line is OK to work with. But if, in fact, the PCM EXPECTS a constant fuel pressure at the fuel rails, then I'm sorry, but then that vacuum line to the fuel pressure regulator does NOT make sense to me because of the above stated reasons.

__________________

|

|

|

02-07-2012, 07:04 PM

02-07-2012, 07:04 PM

|

#1358

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,127

Name : Rich Zuchowski

|

And while I am thinking of this, can anyone tell me if the stock fuel filter/regulator has a similar in function vacuum line running to it?

I sure didn't see one......

__________________

|

|

|

02-08-2012, 08:10 AM

02-08-2012, 08:10 AM

|

#1359

|

|

Deceased

Join Date: Mar 2009

Location: Muncie, Indiana

Posts: 147

Name : John Robinson

|

Banjop fittings

Banjop fittings

I have tried in vane to find a chart that gives the diemensions of the banjo but can not find one. Looking at the picture again it looks like there is an adapter in the fuel rail so they could put in a plug. You might try removing the plug and the adapter and going to a hyd hose supplier and see if they have a banjo fitting that would go directly into the fuel rail without the adaptor. That might get you the clearace you need.

|

|

|

02-08-2012, 01:14 PM

02-08-2012, 01:14 PM

|

#1360

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,127

Name : Rich Zuchowski

|

Thanks for looking for me. I've also been looking and asking around, with no luck. Nate at NastyPerformance suggested that I may just have to bite the bullet and cut the firewall, as it actually would be best to have flow all the way through the fuel rails. Which my gut feeling agrees with, but was hoping I wouldn't have to butcher anything else on the car in order to accomplish that. If I HAVE to go that route, I'm thinking a 180 degree fitting will give me the least amount of cutting I will have to do to the firewall to clear it. If I put in a 90 degree, then the fitting for the hose will be hitting back there, and I would have to remove more firewall to clear it. Maybe I'll see if there is something like a 120 degree fitting. That might give me a better angle for that braided hose plus keep the fitting clear of the firewall. Otherwise if I go with a 180, I would likely use another 90 degree on the end of that 180 to point the hose toward the regulator.

I'll still have to cut enough of the firewall away to keep the fuel rail and/or hose fitting from hitting the firewall from movement of the engine under torque, though. Things would get REAL messy in a hurry having a fuel rail fitting BREAK OFF while under WOT conditions....

While I'm thinking of it, I guess I could always try to form an aluminum panel for that hole so it just doesn't look like a gaping hole in the firewall. I would like it to at least LOOK like a professional job.

__________________

|

|

|

|

Currently Active Users Viewing This Thread: 3159 (0 members and 3159 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -4. The time now is 06:39 AM.

|