|

| Maintenance, Mods, & Tips Mods | Tips | Repairs & Troubleshooting |

|

|

02-06-2013, 05:16 PM

02-06-2013, 05:16 PM

|

#2021

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,134

Name : Rich Zuchowski

|

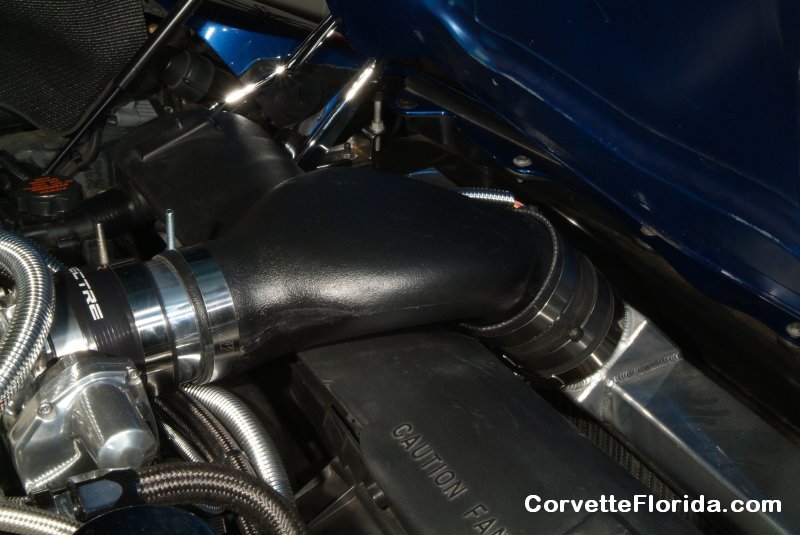

Haven't gotten a new tune lately, so I decided to pull off the airbridge to try to bulletproof that entire air path. Just as well I did, because the lower opening of the airbridge was partially collapsed where I couldn't see it while installed, so likely boost was leaking at that point. I've got some metal tubing, so I'm working on forming the airbridge openings around the tubing so I can clamp those T-bolt clamps TIGHT around it. I'm also seeing if I can lower that airbridge a little bit to give more hood clearance.

Had to order some more 3.5 inch diameter pipe and some extra couplers from Summit, so the car will be down for a couple of days.

Oh well, supposed to get rain tomorrow and Friday anyway....

__________________

|

|

|

02-06-2013, 08:44 PM

02-06-2013, 08:44 PM

|

#2022

|

|

!ereH nI depparT m'I pleH

Join Date: Jan 2007

Location: 25 miles south of Boston, MA. Also have a house in Dunedin FL.

Posts: 1,927

Name : Andy Anderson

|

Quote:

Originally Posted by Rich Z

Oh well, supposed to get rain tomorrow and Friday anyway....

|

The forecast for Friday and Saturday up here calls for from 12 to 24 inches of snow. I'll be more than glad to swap with you!

Andy

|

|

|

02-06-2013, 09:50 PM

02-06-2013, 09:50 PM

|

#2023

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,134

Name : Rich Zuchowski

|

Quote:

Originally Posted by navy2kcoupe

The forecast for Friday and Saturday up here calls for from 12 to 24 inches of snow. I'll be more than glad to swap with you!

Andy  |

Thanks, but no thanks. I would be just as happy to go to my grave without EVER seeing snow in person again.

Highs are forecast to be in the low to mid 70s for the next several days.

Just sayin' ..........

__________________

|

|

|

02-06-2013, 10:03 PM

02-06-2013, 10:03 PM

|

#2024

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,134

Name : Rich Zuchowski

|

Well, I will say one thing about these plastic airbridges. With the right sized metal pipe and a heat gun, you can pretty much form them however you want to. Wish my little lathe was big enough to handle 3.5" diameter pipe, as I've got a piece of aluminum tubing that I would like to remove some metal from the inside of. The only aluminum tubing I could find with 3.75" outside diameter has a quarter inch wall, which is really too much to be used in my intake. I've got a piece of mild steel with that outside diameter and about an eighth inch wall, which will do, but I just don't like to use anything that can rust anywhere on the car.

__________________

|

|

|

02-06-2013, 10:14 PM

02-06-2013, 10:14 PM

|

#2025

|

|

Member

Join Date: Jan 2010

Location: Boston Georgia

Posts: 213

Name : BENJAMIN LONG SR.

|

Quote:

Originally Posted by Rich Z

Well, I will say one thing about these plastic airbridges. With the right sized metal pipe and a heat gun, you can pretty much form them however you want to. Wish my little lathe was big enough to handle 3.5" diameter pipe, as I've got a piece of aluminum tubing that I would like to remove some metal from the inside of. The only aluminum tubing I could find with 3.75" outside diameter has a quarter inch wall, which is really too much to be used in my intake. I've got a piece of mild steel with that outside diameter and about an eighth inch wall, which will do, but I just don't like to use anything that can rust anywhere on the car.

|

the reduction in flow using the 1/4" wall pipe will be negated by being able to actually seal in all the boost.

I wouldn't worry about it a bit.

EDIT: I think you are saying it won't fit inside the bridge, if so, I am unsure what to suggest....

get the steel rings made to your liking and I will powdercoat them for you so they won't rust.

__________________

Life is hard. It's much harder when you're stupid.

|

|

|

02-06-2013, 11:09 PM

02-06-2013, 11:09 PM

|

#2026

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,134

Name : Rich Zuchowski

|

Quote:

Originally Posted by Benjamin

the reduction in flow using the 1/4" wall pipe will be negated by being able to actually seal in all the boost.

I wouldn't worry about it a bit.

EDIT: I think you are saying it won't fit inside the bridge, if so, I am unsure what to suggest....

get the steel rings made to your liking and I will powdercoat them for you so they won't rust.

|

Actually, both the steel and aluminum pipe (tube) are 3.75" outside diameter, so either will work in the bottom opening of the airbridge. And that seems to be pretty close to the outside diameter of the section of the MAF housing I need to attach the airbridge to. If attaching the airbridge directly to the MAF housing won't work for me, then I will have to use one or the other tube as a support ring inside the airbridge when I put a coupler between the bridge and the MAF housing.

Yeah, I hear what you are saying about boost but I would still feel better about having the air flow as unrestricted as possible. But truth be known, the MAF housing itself is actually a restriction in the airflow. Easy to see when you are trying to find the correct diameter couplings for everything. So you are probably right, it really doesn't matter much.

But in any event, the reason that attaching the airbridge to the MAF housing might not work is because I will have to move the airbridge more forward than it has been. So I'm not sure it will fit underneath the hood, since it was already pretty tight there, and the hood slopes downwards the closer it gets to the front of the car. But removing a coupler at the front also changes the angle of the airbridge, so I really won't know till I just try it. I may even have to cut out some of the radiator support itself, if need be.

But right now I can't tell for sure, as I have the upper radiator support out. The blue painted one I've had on the car has a crack in the cover, so I'm either going to fix it or put my stock black one back on. It never was on there right since I brought it back home as the fans and shroud have been sticking too far backwards and not fitting flush against the backside of the radiator like it should be. So I need to look it over closely to see why that is. Besides, I'm thinking about putting insulation on the underside of the support to try to shield the airbridge from the heat from the radiator a bit. So while the airbridge and couplers are out, this is the time to take a look at all that.

At the upper part of the airbridge I have a 3.5" polished aluminum pipe that I can either use as a support ring in the airbridge opening, or if I need some additional length, just don't cut is so short so it can run to the coupler on the throttle body. Lord knows I've got enough T-bolt clamps now. With all the couplers and pipes I've got, I'm sure I will be able to get something to work OK. And if not, well, there's enough stuff available from places I've stumbled upon looking for this airbridge pipe where I may just have to try my hand at fabricating something to just take the place of the airbridge completely. I'll probably wind up wishing I had kept my welder I gave away years ago. But not that I ever really learned to weld, anyway.

I even had my old aluminum BBK airbridge out to see if I was overlooking something about getting that to work properly, but doesn't look like it will unless I can take metal off of the bridge ends or the opening in the intercooler to bring it down so the hood isn't hitting it.

Thanks for the offer of the powder coating. I may take you up on it if it comes to my having to use that steel tube.

__________________

|

|

|

02-08-2013, 12:24 AM

02-08-2013, 12:24 AM

|

#2027

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,134

Name : Rich Zuchowski

|

I wound up putting my old stock upper radiator support back in, as it just seemed to fit better than the blue one I had been using. Plus the paint on the blue finished one was getting kind of beat looking from what it has been though the last few years. I was able to get the radiator positioned better so that the fan shroud is now flush up against the radiator. I also lined the underside of the support with some adhesive backed insulation while I was at it to try to shield the airbridge a little bit from heat coming from the radiator beneath it.

Still got some minor snags, but the airbridge went in pretty well. Connie was helping me with this step of the process. She seems to get a kick out of helping me in the garage. I was able to slide the lower end of the airbridge over the end of the MAF housing, so I didn't need to use that steel tubing, and I cut off a section of the 3.5" aluminum tube to go into the upper section and mate that to a rubber coupler to the throttle body. That rubber coupler is a 4" to 3.5" adapter, needed to mate that throttle body to the airbridge. So the aluminum tube bridges the gap between the rubber coupler and the airbridge, allowing me to get a nice secure fit with the T-bolt clamps.

As for the snags, I didn't have exactly the sizes I needed for a couple of those T-bolt clamps. Apparently they are VERY specific to the application needed, with only about three tenths of an inch leeway between the lower and upper limit to the size of connection they will work with. So you pretty much have to measure for EXACTLY the size you need. On the lower section of the airbridge I had to put a piece of rubber coupler over top of the airbridge itself to allow that clamp to seal. Then on the rubber coupling between the throttle body and the aluminum tube coming from the airbridge, the clamp I used there on the aluminum tube is bottomed out. It's snug, but I'm just not comfortable that it is TIGHT. So that means another order for Summit Racing.  While I was at it, I also ordered T-bolt clamps for as much of the rest of the STS plumbing that I could reach without taking anything apart to get to the connections. Hopefully I measured the diameters correctly. Like I said, there is very little room for guesstimating what you need with those T-bolt clamps.

Anyway, I snugged everything down, then started up the engine to allow the airbridge to get hot enough to be flexible, then cranked down the T-bolts to form the ends of the airbridge to the aluminum tube at the top, and the MAF housing on the bottom. I could FEEL the bolts tighten up, so obviously the plastic of the airbridge was pretty pliable then. When I installed the aluminum tube back into the bridge after cutting the tube to the size I needed (got to use my bandsaw, yay!), I already had to re-heat the airbridge just to get the tube back into it. So it should be pretty snug in there now, and hopefully be an airtight fit.

Also, I didn't realize how much thread would be showing on those T-bolt clamps, so I'm going to have to reposition them. Just looks goofy the way it is now with them sticking straight up into the air alongside the airbridge and couplers, but it's fixable. I figure I'll do that when I get the proper sized clamps in from Summit.

But one thing for sure, the airbridge fits a WHOLE lot better now like this. Lots of clearance between it and the hood now. I guess I can even put that hood liner in that I've had sitting in it's box for the last couple of years.

__________________

|

|

|

02-08-2013, 09:00 AM

02-08-2013, 09:00 AM

|

#2028

|

|

Sinister C4

Join Date: Jan 2007

Location: Largo, FL

Posts: 1,223

Name : Eric G

|

Yeah those t-bolt clamps are crazy. I have them on my silicone radiator hoses...one day I'll pull out the dremel and knock the bolts down a bit. They sure work well when you have the "prefect" size, as they are certainly limiting, but they seal so nice and look great when you hide those massive bolts.

On a side note, when it's time for a paint job, you should have that fast intake painted body color. Would look sharp with all the chrome wire loom.

|

|

|

02-08-2013, 12:00 PM

02-08-2013, 12:00 PM

|

#2029

|

|

Internet Sanitation Engineer

Join Date: Mar 2006

Location: Crawfordville, FL

Posts: 15,134

Name : Rich Zuchowski

|

Looks like I won't be getting my Summit stuff till Monday. But yeah, I'm going to try to hide those bolts better I was looking closely at the pics last night and I'm wondering if I have the MAF connector sitting too high. I may have to adjust that as well if it's too close to the hood.

As for painting the intake manifold, yeah, that probably would look pretty sharp, but to be perfectly honest, once I've got everything running right, I'm not taking anything apart again unless I have no choice in the matter. Meaning, if the world won't end if I DON'T do it, then I'm not taking ANYTHING apart again.

__________________

|

|

|

02-08-2013, 05:14 PM

02-08-2013, 05:14 PM

|

#2030

|

|

Sinister C4

Join Date: Jan 2007

Location: Largo, FL

Posts: 1,223

Name : Eric G

|

Yeah, I certainly understand that one...but I figured since you've done it a couple of times now, thought it might be fairly easy. Hey it's a project car, so you'll need something to do to it down the road. LOL

|

|

|

|

Currently Active Users Viewing This Thread: 6966 (0 members and 6966 guests)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -4. The time now is 09:47 AM.

|