grumpyvette

retired mech engineer

http://www.tavia.com/free_degree_wheel.html

read thru the links on this old thread

http://www.thedirtforum.com/chevyvalves.htm

http://www.2quicknovas.com/happyvalves.html

http://www.jimcookperformance.com/TechNotes/TN7ValvLash.html

http://www.centuryperformance.com/valveadjustment.asp

http://www.babcox.com/editorial/us/uhs89720.htm

http://www.boostandfuel.com/support/setting_valves.htm

http://www.carcraft.com/techarticles/87998/index2.html

http://www.angelfire.com/fl4/pontiacdude428/valveadj.html

http://www.chevytalk.org/threads/showfla...rue#Post1178811

this may help

after doing several comparisons between just installing a cam (DOT-to-DOT)

VS degreeing them in correctly, Im forced to point out that it depends to a HUGE extent on the CAM and how well it meets the specs.

while most cams Ive degreed in were well within about 2 degrees Ive seen some that were out of spec significantly (6 degs plus) if your useing a well known brand like CROWER,CRANE,LUNATI,ISKY etc. youll probably be fine, buy a bargin basement kit and your chances get better on problems, but youll still likely be ok. but degree it in correctly and you could easily gain(OR MORE CORRECTLY NOT CHEAT YOURSELF OUT OF, 5-10 hp) if the cams close to correct, if its well out side specs, youll never know it without degreeing it in and youll wonder whats wrong?

link to thread

keep in mind the cam may be within specs, and the roller chain gears or cam drive gears or the crank keyways ETC. may be out of speck also, thats one reason degreeing in the cam helps find problems

summit [color:"red"] $11 [/color] part # SUM-901064

ID ADVISE you spend the BIG BUCKS and get one before you screw up the crank or keyway

ways to turn over the engine WITHOUT the starter

theres large bolts for your ballancer

theres crank sockets

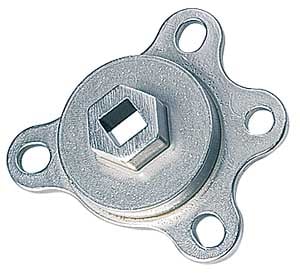

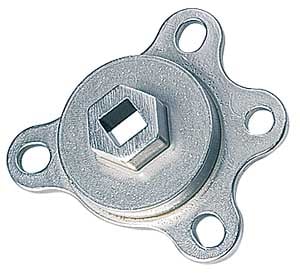

Crankshaft Socket Tool For turning AND MOUNTING Degree Wheels

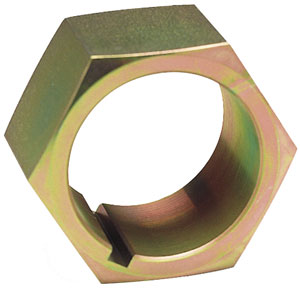

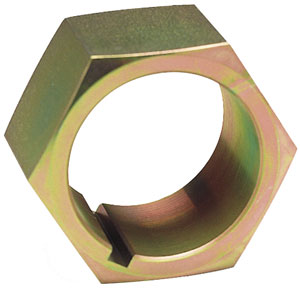

CRANK NUTS

crank rotaters

flywheel turning tools

and your going to need at least one when you degree in a cam or do a compression or leakdown test

http://www.jegs.com/cgi-bin/ncommerce3/ProductDisplay?prrfnbr=3292&prmenbr=361

this kit comes with a video tape instructions and most of the tools needed

its not a bad deal

HERES instructions to read over

http://www.thedirtforum.com/degree.htm

http://www.hotrodder.com/kwkride/degree.html

http://www.454ss.com/whitess/Camshaft.htm

http://www.cranecams.com/?show=article&id=3

http://www.holley.com/HiOctn/TechServ/TechInfo/IECCTech8.html

http://www.moroso.com/catalog/categorydisplay.asp?catcode=27019

http://www.moroso.com/catalog/categorydisplay.asp?catcode=27015

moroso and TAVIA

http://www.tavia.com/cat0.html

carry most other tools youll need

read thru the links on this old thread

http://www.thedirtforum.com/chevyvalves.htm

http://www.2quicknovas.com/happyvalves.html

http://www.jimcookperformance.com/TechNotes/TN7ValvLash.html

http://www.centuryperformance.com/valveadjustment.asp

http://www.babcox.com/editorial/us/uhs89720.htm

http://www.boostandfuel.com/support/setting_valves.htm

http://www.carcraft.com/techarticles/87998/index2.html

http://www.angelfire.com/fl4/pontiacdude428/valveadj.html

http://www.chevytalk.org/threads/showfla...rue#Post1178811

this may help

after doing several comparisons between just installing a cam (DOT-to-DOT)

VS degreeing them in correctly, Im forced to point out that it depends to a HUGE extent on the CAM and how well it meets the specs.

while most cams Ive degreed in were well within about 2 degrees Ive seen some that were out of spec significantly (6 degs plus) if your useing a well known brand like CROWER,CRANE,LUNATI,ISKY etc. youll probably be fine, buy a bargin basement kit and your chances get better on problems, but youll still likely be ok. but degree it in correctly and you could easily gain(OR MORE CORRECTLY NOT CHEAT YOURSELF OUT OF, 5-10 hp) if the cams close to correct, if its well out side specs, youll never know it without degreeing it in and youll wonder whats wrong?

link to thread

keep in mind the cam may be within specs, and the roller chain gears or cam drive gears or the crank keyways ETC. may be out of speck also, thats one reason degreeing in the cam helps find problems

summit [color:"red"] $11 [/color] part # SUM-901064

ID ADVISE you spend the BIG BUCKS and get one before you screw up the crank or keyway

ways to turn over the engine WITHOUT the starter

theres large bolts for your ballancer

theres crank sockets

Crankshaft Socket Tool For turning AND MOUNTING Degree Wheels

CRANK NUTS

crank rotaters

flywheel turning tools

and your going to need at least one when you degree in a cam or do a compression or leakdown test

http://www.jegs.com/cgi-bin/ncommerce3/ProductDisplay?prrfnbr=3292&prmenbr=361

this kit comes with a video tape instructions and most of the tools needed

its not a bad deal

HERES instructions to read over

http://www.thedirtforum.com/degree.htm

http://www.hotrodder.com/kwkride/degree.html

http://www.454ss.com/whitess/Camshaft.htm

http://www.cranecams.com/?show=article&id=3

http://www.holley.com/HiOctn/TechServ/TechInfo/IECCTech8.html

http://www.moroso.com/catalog/categorydisplay.asp?catcode=27019

http://www.moroso.com/catalog/categorydisplay.asp?catcode=27015

moroso and TAVIA

http://www.tavia.com/cat0.html

carry most other tools youll need