Cor66Vette

New member

Is there a forum member who is versed in trouble shooting a battery gauge (1966) who can offer some technical help? To me, this appears elementary, so I must be missing something.

The gauge never did work since I've had the car and since I knew the charging system is okay, I never bothered with it. I just now decided to check it out.

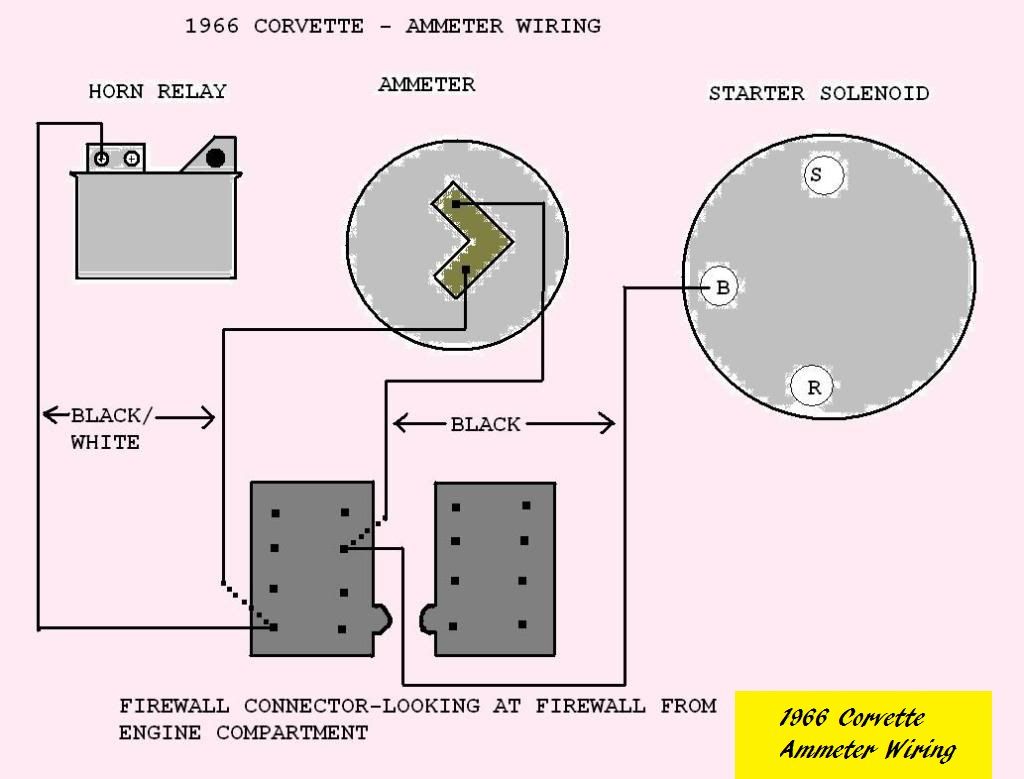

Here's a simple drawing

Here's what is going on-

The gauge doesn't move, just sits at zero.

I used a AAA battery and jumped it across the terminals of the gauge and got deflection on the needle.

When I reversed polarity, the needle moved in the opposite direction.

So I am assuming the gauge is okay.

I checked for 12vdc at the gauge and I get voltage on each of the two wires feeding the gauge. 12.65 vdc engine off and 14.85 at 1200 RPM. I checked for continuity at the source of the feed for each wire and determined that the sources are not common, so the gauge should pick up differential in current. I cleaned the terminals on the gauge and I jumped the connector to the gauge in case the connection was bad when plugged into the gauge.

The feed from the horn relay is separate from the feed from the starter and that I proved.

Well, this is where I'm at and I am out of ideas. If anyone can suggest a course for me to take, I will follow it.

Thank you.

*edit* now the gauge is stuck to one side but it deflects:shrug01:

The gauge never did work since I've had the car and since I knew the charging system is okay, I never bothered with it. I just now decided to check it out.

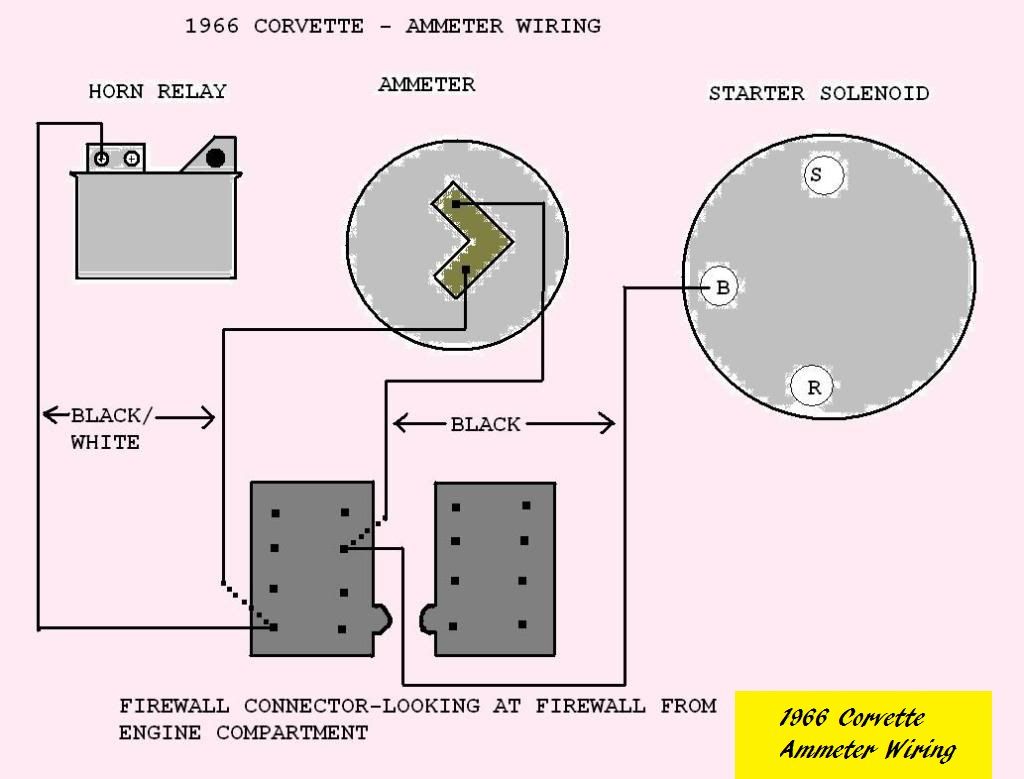

Here's a simple drawing

Here's what is going on-

The gauge doesn't move, just sits at zero.

I used a AAA battery and jumped it across the terminals of the gauge and got deflection on the needle.

When I reversed polarity, the needle moved in the opposite direction.

So I am assuming the gauge is okay.

I checked for 12vdc at the gauge and I get voltage on each of the two wires feeding the gauge. 12.65 vdc engine off and 14.85 at 1200 RPM. I checked for continuity at the source of the feed for each wire and determined that the sources are not common, so the gauge should pick up differential in current. I cleaned the terminals on the gauge and I jumped the connector to the gauge in case the connection was bad when plugged into the gauge.

The feed from the horn relay is separate from the feed from the starter and that I proved.

Well, this is where I'm at and I am out of ideas. If anyone can suggest a course for me to take, I will follow it.

Thank you.

*edit* now the gauge is stuck to one side but it deflects:shrug01:

Last edited: