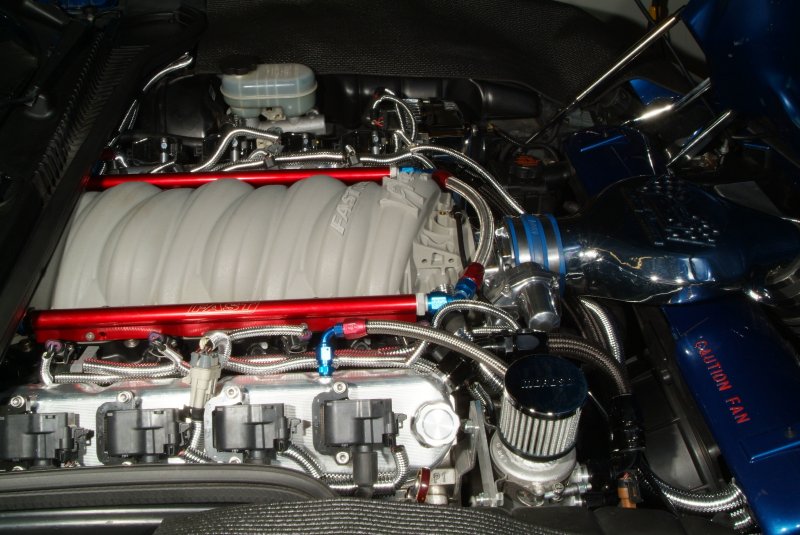

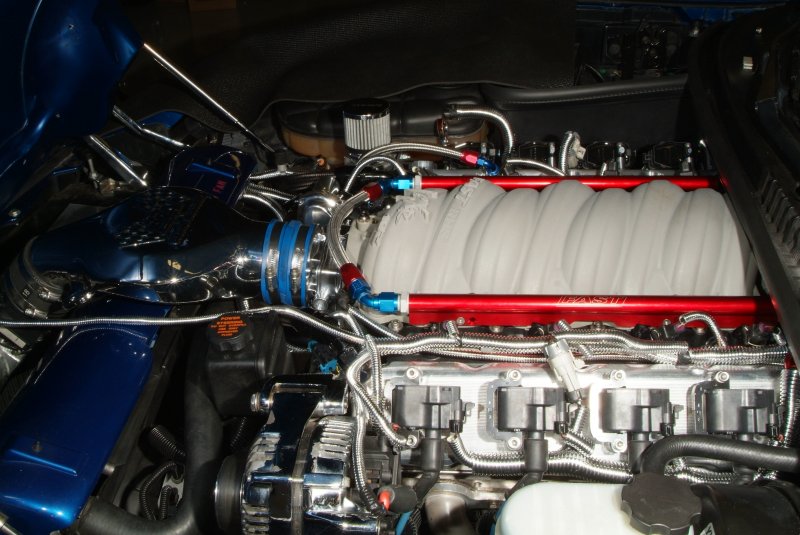

Put the LS2 throttle body on today. Also put some more insulating tubing on some wiring and untangled some messes. Need to still lay out the wires and wrap them up to make them neater now, though.

Noticed a couple of things that are unsettling, though.

First off, apparently Aaron drilled a hole through the throttle body blade on the one that he installed on my car. I hope the guy I am sending it back as a core doesn't kick it back as being unacceptable this way.

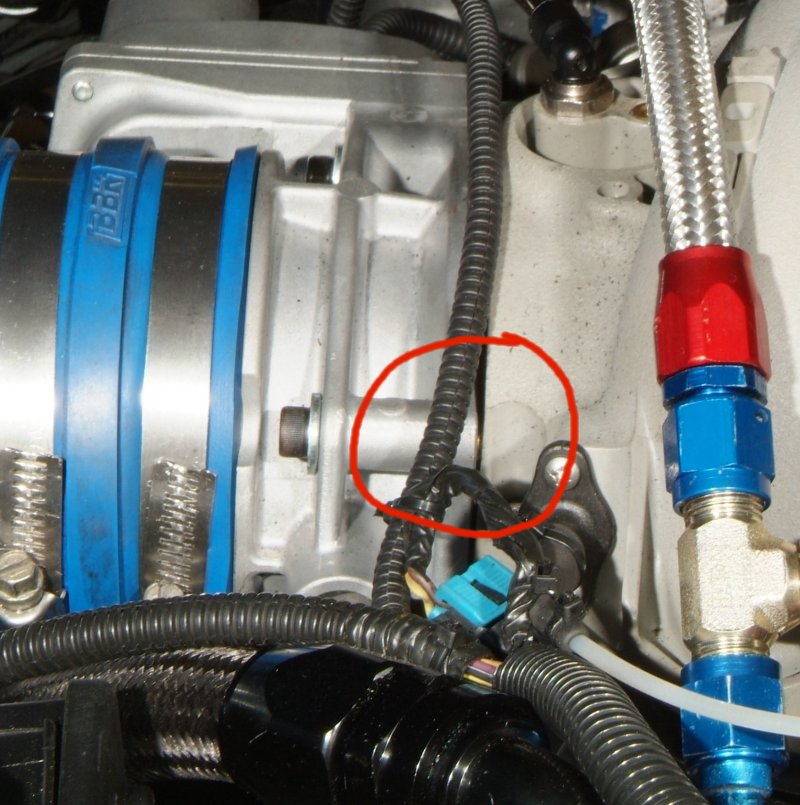

I also noticed that there was a bit of oil at the bottom of the old throttle body when I pulled it off of the intake manifold. So thinking about the warning about fluids in the intercooler, and recalling that Aaron had had at least three instances that I am aware of where oil had gotten into the intake of the turbo plumbing, I decided to pull off the blow off valve to take a look into the bottom of the intercooler. Fortunately everything looked OK in there, with just a light film of gunk, but I found that the o-ring seal for the blow off valve was broken.

Great......

Then to top all of this off, I noticed that the throttle body isn't fitting flush against the front of the intake manifold. The mounting flange for this LS2 throttle body doesn't seem to be as wide as the LS3/LS7 throttle body I took off, and since it isn't fitting flush I could see the throttle body seal peaking out from behind the throttle body. I checked some older pics, and evidently this gap was there when I got the car back home, but it just wasn't noticeable since the orange o-ring wasn't visible. I hope this darn thing is sealing properly. Otherwise I don't have any idea what I would need to do about it. BTW, it appears that the brass mount in the FAST intake that the throttle body bolts to is sticking out a bit, which is making that gap I see.

One step forward and two steps back....... :banghead:

Now I've got to find a blowoff valve o-ring and wait for that to show up. Then be on pins and needles hoping that throttle body is sealed to the intake manifold.