-

Got the Contributing Memberships stuff finally worked out and made up a thread as a sort of "How-To" to help people figure out how to participate. So if you need help figuring it out, here's the thread you need to take a look at -> http://www.corvetteflorida.com/forums/showthread.php?t=3581 Thank you, everyone! Rich Z.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

427 engine (part 2) - RHS block

- Thread starter Rich Z

- Start date

Well, I talked to Shane this evening.

Not any good news, I'm afraid.

He said the slave cylinder was completely destroyed. Apparently the torque tube is damaged as well. And I think he said the pilot bearing is screwed up, but honestly, my mind started freezing over when he mentioned that the end of the crank might be damaged. He is going to check into this further tomorrow. He's not sure about the status of the drive shaft itself as he's not real certain on what exactly went wrong.

I'm not sure where it's going to go from here. But if the crank shaft is damaged, then the game is over with. I will be done. If the crank has to be replaced, then I am finished with it. Heck, if a new torque tube is going to cost me a bunch of money, it may be over with anyway.

I guess I need to see just what sort of ducks I am dealing with before I can even think about trying to get them all lined up in a row.

I guess I've got another sleepless night ahead of me again...

Not any good news, I'm afraid.

He said the slave cylinder was completely destroyed. Apparently the torque tube is damaged as well. And I think he said the pilot bearing is screwed up, but honestly, my mind started freezing over when he mentioned that the end of the crank might be damaged. He is going to check into this further tomorrow. He's not sure about the status of the drive shaft itself as he's not real certain on what exactly went wrong.

I'm not sure where it's going to go from here. But if the crank shaft is damaged, then the game is over with. I will be done. If the crank has to be replaced, then I am finished with it. Heck, if a new torque tube is going to cost me a bunch of money, it may be over with anyway.

I guess I need to see just what sort of ducks I am dealing with before I can even think about trying to get them all lined up in a row.

I guess I've got another sleepless night ahead of me again...

shakedown067

Sinister C4

Yeah, I sure would like to know "the rest of the story" on that one....

From what I remember reading, the vette spun out and hit the wall. Was damaged and he didn't get to request a tow truck. The highway patrol ordered the car be cleared, so the tow truck hooked up and drugged it off. It was already damaged. And no, you usually have to sign a waiver before they'll even touch your car stating they aren't liable for ANY damages.

Sorry to hear about the news on the car Rich. Hope it's not as bad as he's making it out to be.

I'm trying to put some pieces of the puzzle together in my head, so please excuse any dumb questions that I throw out here.

How does the clutch slave cylinder mount in the drivetrain? It looks like it has a couple of mounting bolt holes, but where exactly does it bolt into?

What keeps the driveshaft from moving FORWARD within the torque tube? I know there is a big snap ring in the back to keep it from moving backwards, but I just haven't looked closely at the front with this in mind.

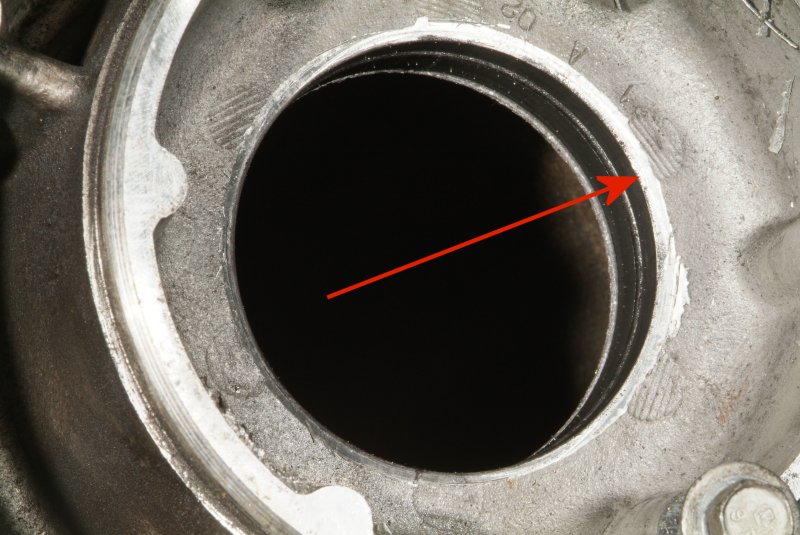

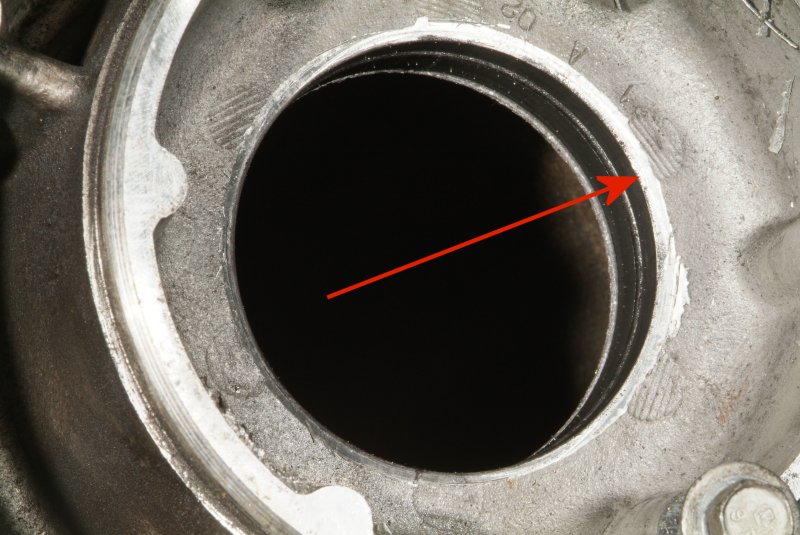

If you pulled your driveshaft out and saw your crankshaft and driveshaft end looking like this, what would you think was the cause?

And then we have the splines in one of the clutch disks....

What happened here?

How does the clutch slave cylinder mount in the drivetrain? It looks like it has a couple of mounting bolt holes, but where exactly does it bolt into?

What keeps the driveshaft from moving FORWARD within the torque tube? I know there is a big snap ring in the back to keep it from moving backwards, but I just haven't looked closely at the front with this in mind.

If you pulled your driveshaft out and saw your crankshaft and driveshaft end looking like this, what would you think was the cause?

And then we have the splines in one of the clutch disks....

What happened here?

navy2kcoupe

!ereH nI depparT m'I pleH

Rich, you may be right. That car seems to have the world's supply of "bad Juju"

locked up! It just may be time to say "enuff", and bail out........although I was

REALLY hoping to see a successful end to this saga............. BUMMER

Andy :wavey:

locked up! It just may be time to say "enuff", and bail out........although I was

REALLY hoping to see a successful end to this saga............. BUMMER

Andy :wavey:

CorvetteJohn

Deceased

All the runs on the dyno with the bell housing moving under torque causing the spline to be crooked in the teeth. That is what I think caused that to happen. I think you have print outs from those runs and if they were pulling the engine to get horsepower and torque numbers. most teeth will hold a lot of torgue if they are mating the full length of the flat. Now if you torgue them so they only are in contact on a patch that is only 4 or 5 thousands wide that is what will happen.

I looks like the spline was pulled out of the mating part because the drive train was being allowed to move with the loose bell housing

I looks like the spline was pulled out of the mating part because the drive train was being allowed to move with the loose bell housing

All the runs on the dyno with the bell housing moving under torque causing the spline to be crooked in the teeth. That is what I think caused that to happen. I think you have print outs from those runs and if they were pulling the engine to get horsepower and torque numbers. most teeth will hold a lot of torgue if they are mating the full length of the flat. Now if you torgue them so they only are in contact on a patch that is only 4 or 5 thousands wide that is what will happen.

I looks like the spline was pulled out of the mating part because the drive train was being allowed to move with the loose bell housing

Well, then if that is the case, the $64 question would be "When did those bolts go missing in the bell housing?"

Benjamin

New member

where is or what's left of the pilot bearing / bushing? it looks to me like there was some sort of failure on it's part looking at the wear on the part of the shaft that goes into the crank, but the other thing is was the driveshaft thingey all the way in the forward position so that ALL the splines were meshed from the clutch disks and the driveshaft thingy?

where is or what's left of the pilot bearing / bushing? it looks to me like there was some sort of failure on it's part looking at the wear on the part of the shaft that goes into the crank, but the other thing is was the driveshaft thingey all the way in the forward position so that ALL the splines were meshed from the clutch disks and the driveshaft thingy?

Well, I should have taken a picture of that pilot bearing. Pfadt wants me to measure the carbon fiber driveshaft, so I guess I'll have to run back there sometime to do that. I guess I should have taken more pics while I was out there, but I was trying to not be underfoot too much.

Shane had speculated that Chris Harwood had put in the wrong carbon fiber drive shaft, so I contact Pfadt about it, and luckily the drive shaft was ordered directly from them, and they were able to find the order. Yes, the drive shaft was for a 2002 C5 Z06. But they still want me to measure it to make sure the correct one was SENT. Shane told me that the drive shaft being too long could likely cause the damage seen, but I'm having trouble understanding how such a thing could happen.

Anyway, I believe Shane said that the problem was that the drive shaft had moved too far FORWARD. I'm trying to figure out how that could happen. I thought that the slave cylinder bolts to the front of the torque tube, so does that hold the drive shaft from moving forward? Obviously SOMETHING must do that, but I just don't know what. I would think at the very least the pilot bearing would stop the shaft from going forward enough to eat into the crank. I watched the video of Chris Harwood having to hammer that bearing into the crank, so it's not like it would just slide in and out on it's own.

As for the driveshaft being too far BACK, heck, I don't know how it could do that either. There is a big snap ring in the back of the torque tube that holds the drive shaft solidly back there. So it shouldn't have been able to move in that direction at all. Aaron Scott told me that he verified that the carbon fiber drive shaft was still in the torque tube when he pulled the transmission and differential to be sent to RPM. I asked him to do that, as I really didn't trust Chris Harwood all that much by that time. As far as I can tell, you really can't tell the carbon fiber drive shaft is in there without removing that snap ring so you can pull it out to see it.

If the splines of the drive shaft weren't fully engaged in the clutch disks, then I would think the car would have made a hellacious racket with one of the disks flopping around. And the drive shaft would have been wobbling around like crazy since likely the shaft would not have been seated in the pilot bearing. Probably would have sounded like a bunch of cats being burned alive in a dryer.

But heck, I'm just trying to figure this all out, and having trouble putting the pieces of the puzzle together. And I'll be quite honest about it, none of this is making any sense to me.

Oh well. I decided I was going to have Shane pull the engine and have it taken to a local engine builder to have it checked out and fix whatever needs to be fixed. But I called him on the phone to talk about it, and he just flatly refused to help me. Didn't want to get involved, he said.

Oh well, not really sure what to do now.

EDIT: I just wanted to clarify what I typed above. I called the ENGINE BUILDER and it was him who refused to help me and did not want to get involved, NOT Shane. It sounded a bit confusing when I read this over later on, and I wanted to make sure it was clear who I was referring to.

Oh well, not really sure what to do now.

EDIT: I just wanted to clarify what I typed above. I called the ENGINE BUILDER and it was him who refused to help me and did not want to get involved, NOT Shane. It sounded a bit confusing when I read this over later on, and I wanted to make sure it was clear who I was referring to.

Last edited:

navy2kcoupe

!ereH nI depparT m'I pleH

That's almost to be expected, given all of the problems that have been uncovered due to

the previous people that worked on it. He probably figures that it will tie him up for

too long a time. Can't say as I blame him on one hand, but on the other, he IS in the

business of working on these cars and to turn down good money doesn't make sense

to me. Unless he's already WAY overbooked and wouldn't be able to get to it for quite awhile

In any case, it's a BUMMER that you had what you thought was a capable person,

and he turned you down.

Andy :wavey:

the previous people that worked on it. He probably figures that it will tie him up for

too long a time. Can't say as I blame him on one hand, but on the other, he IS in the

business of working on these cars and to turn down good money doesn't make sense

to me. Unless he's already WAY overbooked and wouldn't be able to get to it for quite awhile

In any case, it's a BUMMER that you had what you thought was a capable person,

and he turned you down.

Andy :wavey:

CorvetteJohn

Deceased

That's almost to be expected, given all of the problems that have been uncovered due to

the previous people that worked on it. He probably figures that it will tie him up for

too long a time. Can't say as I blame him on one hand, but on the other, he IS in the

business of working on these cars and to turn down good money doesn't make sense

to me. Unless he's already WAY overbooked and wouldn't be able to get to it for quite awhile

In any case, it's a BUMMER that you had what you thought was a capable person,

and he turned you down.

Andy :wavey:

He may not want to become associated with the workmanship of the other two shops reflecting on his workmanship. He obviously knows how observant Rich is (rightfully so with what he has uncovered from the others who worked on the car) and just does not want to risk his good reputation on something he has no control over how the finished work will hold up. If that is the case maybe if they sit down and talk about this situation he will reconsider and do the work or at the very least Rich will understand why he said no.

I guess I resent the implication that I'm so stupid that I couldn't recognize where someone's responsibility lies and where it ends in something like this. With the work that Chris Harwood did and Aaron Scott did on my car, I usually KNOW who did what and who did NOT do what when I find a problem. I have a pretty good idea in what instances I was lied to, taken advantage of, stolen from, and basically treated like a cash cow. And if I don't know immediately, eventually I will find out as I learn more about the issue at hand. And as is also pretty obvious in hindsight, some people knew long before I did just how badly I was getting screwed all along the way here in this thread, simply because they had the experience level to recognize things I could not see. My biggest problem was that I trusted the people I was dealing with. At least up to the point where what they were telling me wasn't matching with what I was seeing.

So yeah, I guess people have seen me post things here that pretty clearly show what I have found concerning the workmanship (or lack thereof) of the people who worked on my car. My guess is that those people who would snub my request of help from them quite probably fear that their own workmanship skills might come up far short from what they claim when viewed in a critical light. I WILL call a spade a "spade" regardless of who it is or what it is about. And I'm pretty sure that is worrisome to some people.

But at least Shane had enough balls to actively help me out now. And my guess is he is probably catching some flak because of it from the "we don't want to get involved" network, too. But he strikes me as the kind of guy who doesn't really give a crap about what other people may think of him or what he does.

So yeah, I guess people have seen me post things here that pretty clearly show what I have found concerning the workmanship (or lack thereof) of the people who worked on my car. My guess is that those people who would snub my request of help from them quite probably fear that their own workmanship skills might come up far short from what they claim when viewed in a critical light. I WILL call a spade a "spade" regardless of who it is or what it is about. And I'm pretty sure that is worrisome to some people.

But at least Shane had enough balls to actively help me out now. And my guess is he is probably catching some flak because of it from the "we don't want to get involved" network, too. But he strikes me as the kind of guy who doesn't really give a crap about what other people may think of him or what he does.

I talked with Bryan at LME yesterday, and he says that ten thousandths crank end play is at the outside edge of what he would consider as acceptable. I also talked with another engine machinist who said it will be OK, and matter of fact he would prefer the end play to be at 0.010 than at 0.005.

Shane is ordering a torque tube assembly for me, since my torque tube is trashed. He called me yesterday evening and said that he pulled out the carbon fiber drive shaft and there are two washers on the shaft that are likely the cause of the excessive length of the shaft. I checked Pfadt's website and looked over the install instructions for the shaft, and I don't see anything mentioned there about any washers. But I want to see the shaft myself to see what washers Shane is referring to.

With all of the reading I've been doing concerning this stuff lately, I did find one little tidbit that I though interesting. Evidently sitting at a stop light with the clutch pressed in the entire time is really hard on the thrust bearing on the crank. Quite honestly, I ALWAYS did that. Evidently the correct thing to do, or at least what is easier on your thrust bearing, is to put the shifter in neutral and let the clutch out. Evidently the throwout bearing being pressed against the fingers of the clutch applies that pressure directly to the crank through the clutch, pushing it FORWARD, and therefore directly against the thrust bearing, causing unnecessary wear.

Bryan at LME told me that replacing the thrust bearing is really easy to do, comparatively, but unfortunately GETTING to that bearing in an engine sitting in a Corvette is NOT all that easy to do.

Shane told me he is going to get a Centerforce clutch for me, that will be a whole lot more streetable than the Fidanza that got trashed. And also going to a steel flywheel, since I think that contributed to some of the problems associated with that Fidanza clutch making all the noise from a dead stop. Of course, seeing all the damage there, no telling what exactly was causing what sort of noises, I guess.

Well, maybe the car will be back together by the end of the week. I told Shane there really isn't any rush on my part. Heck the car has spent nearly all of the time sitting on a lift since I drove it home from Aaron Scott's place anyway.

Shane is ordering a torque tube assembly for me, since my torque tube is trashed. He called me yesterday evening and said that he pulled out the carbon fiber drive shaft and there are two washers on the shaft that are likely the cause of the excessive length of the shaft. I checked Pfadt's website and looked over the install instructions for the shaft, and I don't see anything mentioned there about any washers. But I want to see the shaft myself to see what washers Shane is referring to.

With all of the reading I've been doing concerning this stuff lately, I did find one little tidbit that I though interesting. Evidently sitting at a stop light with the clutch pressed in the entire time is really hard on the thrust bearing on the crank. Quite honestly, I ALWAYS did that. Evidently the correct thing to do, or at least what is easier on your thrust bearing, is to put the shifter in neutral and let the clutch out. Evidently the throwout bearing being pressed against the fingers of the clutch applies that pressure directly to the crank through the clutch, pushing it FORWARD, and therefore directly against the thrust bearing, causing unnecessary wear.

Bryan at LME told me that replacing the thrust bearing is really easy to do, comparatively, but unfortunately GETTING to that bearing in an engine sitting in a Corvette is NOT all that easy to do.

Shane told me he is going to get a Centerforce clutch for me, that will be a whole lot more streetable than the Fidanza that got trashed. And also going to a steel flywheel, since I think that contributed to some of the problems associated with that Fidanza clutch making all the noise from a dead stop. Of course, seeing all the damage there, no telling what exactly was causing what sort of noises, I guess.

Well, maybe the car will be back together by the end of the week. I told Shane there really isn't any rush on my part. Heck the car has spent nearly all of the time sitting on a lift since I drove it home from Aaron Scott's place anyway.

CorvetteJohn

Deceased

I guess I resent the implication that I'm so stupid that I couldn't recognize where someone's responsibility lies and where it ends in something like this. With the work that Chris Harwood did and Aaron Scott did on my car, I usually KNOW who did what and who did NOT do what when I find a problem. I have a pretty good idea in what instances I was lied to, taken advantage of, stolen from, and basically treated like a cash cow. And if I don't know immediately, eventually I will find out as I learn more about the issue at hand. And as is also pretty obvious in hindsight, some people knew long before I did just how badly I was getting screwed all along the way here in this thread, simply because they had the experience level to recognize things I could not see. My biggest problem was that I trusted the people I was dealing with. At least up to the point where what they were telling me wasn't matching with what I was seeing.

So yeah, I guess people have seen me post things here that pretty clearly show what I have found concerning the workmanship (or lack thereof) of the people who worked on my car. My guess is that those people who would snub my request of help from them quite probably fear that their own workmanship skills might come up far short from what they claim when viewed in a critical light. I WILL call a spade a "spade" regardless of who it is or what it is about. And I'm pretty sure that is worrisome to some people.

But at least Shane had enough balls to actively help me out now. And my guess is he is probably catching some flak because of it from the "we don't want to get involved" network, too. But he strikes me as the kind of guy who doesn't really give a crap about what other people may think of him or what he does.

I apologize if it sounded like I was criticizing you in any way. My intent was to suggest that Shane would certainly know how you had been treated before and the care that you took to right things you found after you got the car back. I know I have been asked to fix things that were done by someone else and I have refused to do it. Not that I could not have done it but because I simply could not devote the time to correct the situation the way I would want to do it. I have followed your workmanship and dedication to getting it right. Not only do you have the eye to find things that are not correct but you also have the work ethic to not just fix it but to get the right materials and do the job in a professional manner. In the past I was flattered that you even considered some of the suggestions I made to solve a problem you were having something. I wish you luck with finally resolving what must surely be the last area that will keep you from enjoying your car.

And now I will sign off for the last time.

I apologize if it sounded like I was criticizing you in any way. My intent was to suggest that Shane would certainly know how you had been treated before and the care that you took to right things you found after you got the car back. I know I have been asked to fix things that were done by someone else and I have refused to do it. Not that I could not have done it but because I simply could not devote the time to correct the situation the way I would want to do it. I have followed your workmanship and dedication to getting it right. Not only do you have the eye to find things that are not correct but you also have the work ethic to not just fix it but to get the right materials and do the job in a professional manner. In the past I was flattered that you even considered some of the suggestions I made to solve a problem you were having something. I wish you luck with finally resolving what must surely be the last area that will keep you from enjoying your car.

And now I will sign off for the last time.

You apparently misunderstood me. I resent that the people I ASKED for help apparently feel that I would be unable to distinguish between what they have done, and what a person or persons have done prior to them laying a hand on the car.

"Sign off for the last time"? Well sorry that you misunderstood my post...

Taking a closer look at the end of the input shaft at the front of the drive shaft, any ideas on what made those deep scratches?

And here's the end of the throwout bearing. Does this look like one that would have been new when Chris Harwood put in my new clutch?

And here's the end of the throwout bearing. Does this look like one that would have been new when Chris Harwood put in my new clutch?

Still working on pieces of the puzzle. Went over to Champion Chevrolet again today and took some more pics. Also brought the carbon fiber driveshaft home with me.

First off, as best I can tell, it appears that the front bearing on the input shaft of the drive shaft must seat in the torque tube on the front edge of this bearing. as the drive shaft installs from the BACK only.....

I'm guessing that it must seat there to keep the driveshaft from moving forward and therefore move that bearing completely out of the torque tube if it were not there.

What apparently happened in my case is whatever lip or retainer that SHOULD be there in the torque tube, somehow just "went away".

Does anyone have a photo of that front area of the torque tube showing EXACTLY what it is that keeps the bearing in place? As you can see, mine is gone, which allowed the driveshaft to MOVE FORWARD and cause all the mayhem that it did. I think I've got a pretty good idea of what happened, but I would like to see this additional puzzle piece before expressing my opinion.

First off, as best I can tell, it appears that the front bearing on the input shaft of the drive shaft must seat in the torque tube on the front edge of this bearing. as the drive shaft installs from the BACK only.....

I'm guessing that it must seat there to keep the driveshaft from moving forward and therefore move that bearing completely out of the torque tube if it were not there.

What apparently happened in my case is whatever lip or retainer that SHOULD be there in the torque tube, somehow just "went away".

Does anyone have a photo of that front area of the torque tube showing EXACTLY what it is that keeps the bearing in place? As you can see, mine is gone, which allowed the driveshaft to MOVE FORWARD and cause all the mayhem that it did. I think I've got a pretty good idea of what happened, but I would like to see this additional puzzle piece before expressing my opinion.