Not too much going on lately. Haven't driven the car much.

I was quite surprised when Shane (from the Chevy dealership) called me yesterday just to check up on how my car was doing. I thought it was right nice of him to follow up.

Anyway, I told him about the noise I am hearing when I first start off out of my driveway. I believe I posted a video earlier of what I am talking about. Been meaning to see if I can duplicate the sound while the car is on the lift, but for one reason or another, just haven't gotten around to doing that.

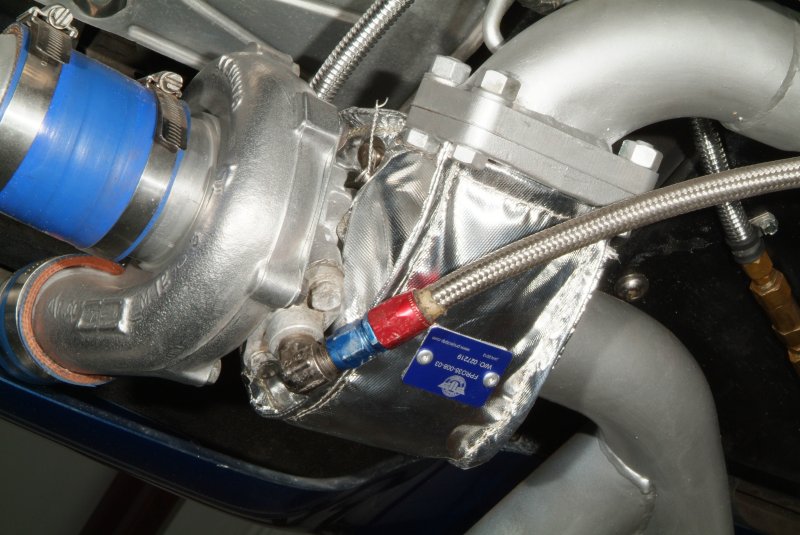

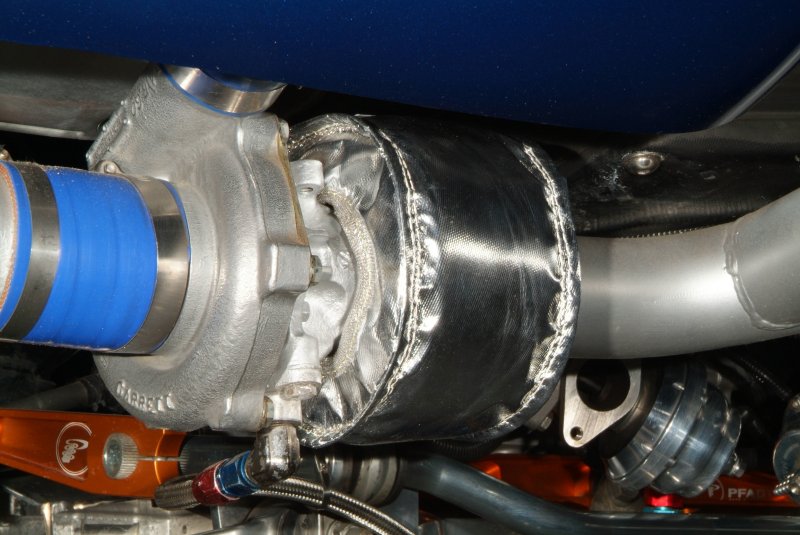

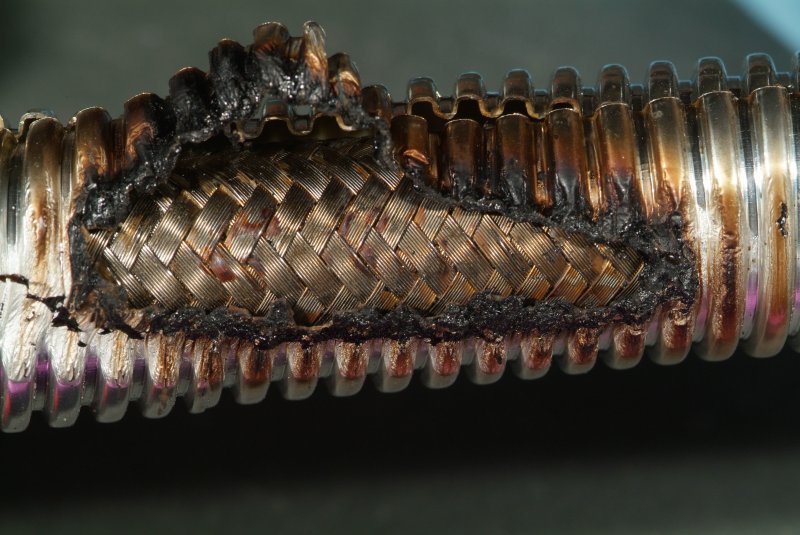

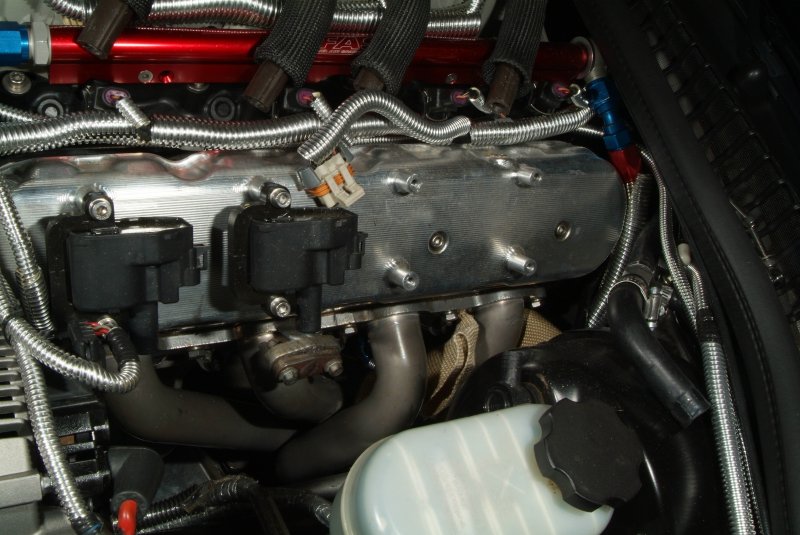

One reason for that is because I found that the insulating convoluted tubing I put around the fuel line coming from the driver's side fuel rail to the fuel pressure regulator had burned through. The fuel line itself looks OK, but obviously that line is too close to the #7 primary header pipe. So I am planning on putting some insulating wrap around the header primary pipes (all of them) to try to reduce the heat they are pumping into the engine compartment. I may completely reroute that fuel line a little bit anyway

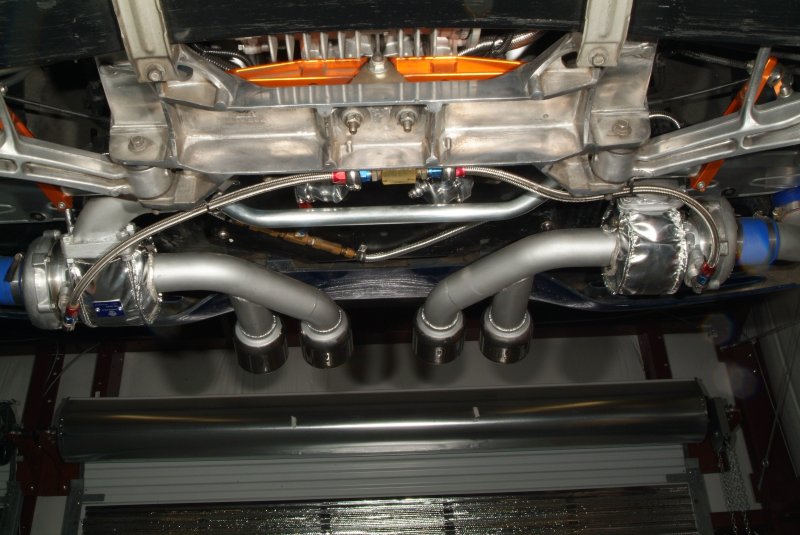

While I am at it, I'm planning on wrapping the entire exhaust system. Seems I have found melted plastic hear and there on the exhaust pipes since bringing the car home a year ago, so maybe it is best I just try to wrap up those hot pipes to try to keep the heat contained within them.

There is also the issue with the evap system not having a line run back to the intake vacuum that I need to see what I can do about. And there are those brackets on the STS pipes that someone bent all to hell that I need to straighten out. Maybe just plugging off the line or maybe putting a check valve in there will work well enough. At this point I just don't know enough about how that system actually works to have a firm idea on what to do about it to end that gasoline smell the car gives off.

Let's see, the upper radiator support is cracked. I fixed it once, but obviously I didn't fix it permanently.

So yeah, still some minor odds and ends left to do. At least what I know about today. I'm hoping that noise I hear is just something minor as well. First step is to identify where it is actually coming from.

Ah well, all in due time.... If I can at least recreate the noise on demand, then perhaps Shane will be able to figure it out without having to do any exploratory surgery.

I was quite surprised when Shane (from the Chevy dealership) called me yesterday just to check up on how my car was doing. I thought it was right nice of him to follow up.

Anyway, I told him about the noise I am hearing when I first start off out of my driveway. I believe I posted a video earlier of what I am talking about. Been meaning to see if I can duplicate the sound while the car is on the lift, but for one reason or another, just haven't gotten around to doing that.

One reason for that is because I found that the insulating convoluted tubing I put around the fuel line coming from the driver's side fuel rail to the fuel pressure regulator had burned through. The fuel line itself looks OK, but obviously that line is too close to the #7 primary header pipe. So I am planning on putting some insulating wrap around the header primary pipes (all of them) to try to reduce the heat they are pumping into the engine compartment. I may completely reroute that fuel line a little bit anyway

While I am at it, I'm planning on wrapping the entire exhaust system. Seems I have found melted plastic hear and there on the exhaust pipes since bringing the car home a year ago, so maybe it is best I just try to wrap up those hot pipes to try to keep the heat contained within them.

There is also the issue with the evap system not having a line run back to the intake vacuum that I need to see what I can do about. And there are those brackets on the STS pipes that someone bent all to hell that I need to straighten out. Maybe just plugging off the line or maybe putting a check valve in there will work well enough. At this point I just don't know enough about how that system actually works to have a firm idea on what to do about it to end that gasoline smell the car gives off.

Let's see, the upper radiator support is cracked. I fixed it once, but obviously I didn't fix it permanently.

So yeah, still some minor odds and ends left to do. At least what I know about today. I'm hoping that noise I hear is just something minor as well. First step is to identify where it is actually coming from.

Ah well, all in due time.... If I can at least recreate the noise on demand, then perhaps Shane will be able to figure it out without having to do any exploratory surgery.