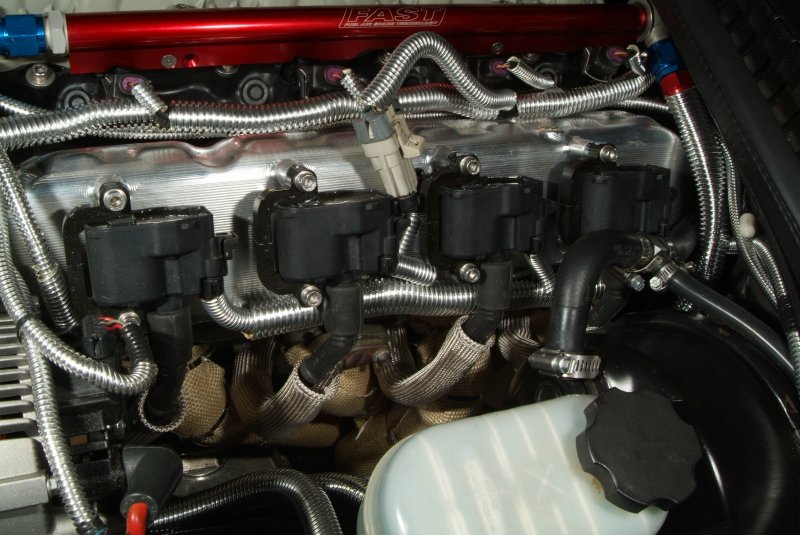

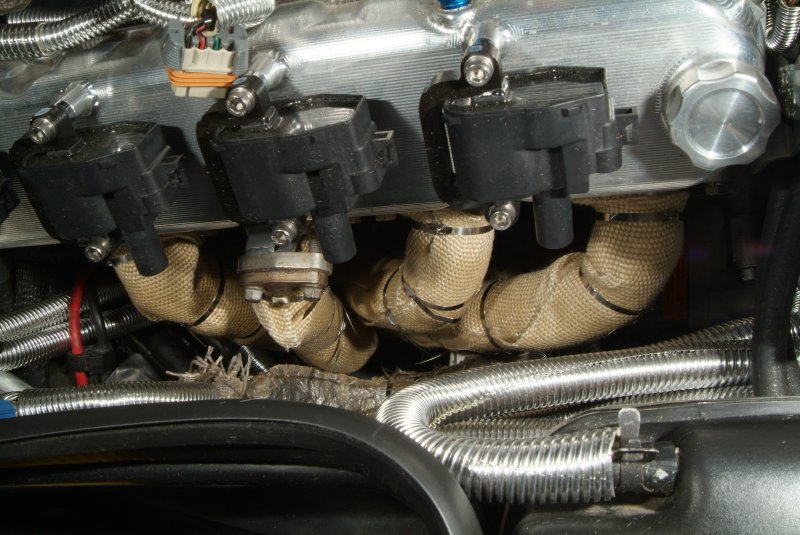

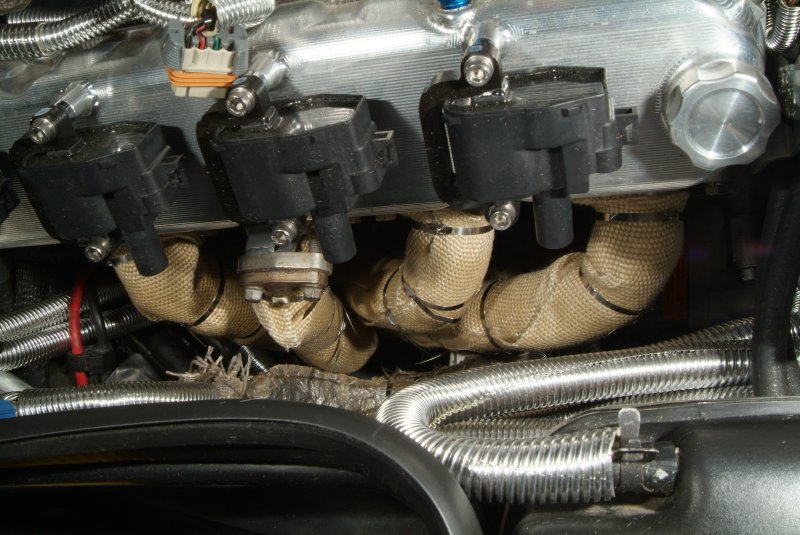

Yesterday I finished up the passenger side header wrap on the primary tubes.

I can't really say that I would want to have to do this again any time soon. :nonod:

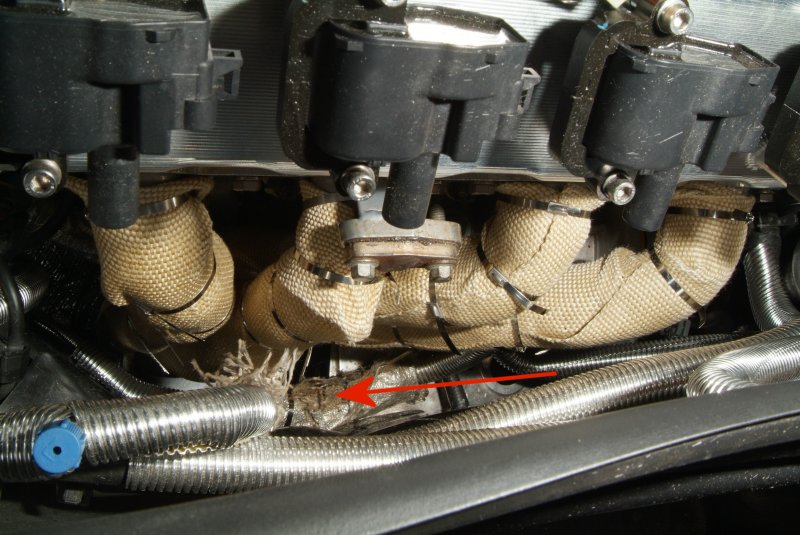

I noticed that a few of the cool socks I had on the ignition wires got heat damaged by apparently laying against the headers, so I had to order a new set of them.

Looks like the heat just bleached the black color out of those socks, but that area is also noticeably softer to the touch, so I'm guessing they are shot once that happens.

Not sure why I chose black cool socks, but this time around I got light colored ones, thinking they would be better at reflecting heat anyway. The black ones were also only 6 inches long, and it looks like 8 inch ones will cover more of the ignition wires and boots.

Also accidentally pulled off one of the ends of one of the ignition wires when trying to get them off of the spark plugs. Luckily I have a couple of extras that were on the car when it was pulled into Chris Harwood's shop, as those Granatelli ignition wires aren't cheap, and I really wouldn't want to have to buy another set of them just to replace that one wire. Maybe I can fix the broken one......... :shrug01:

I didn't do anything at all today on the car. I think I tried way too hard yesterday to try to make my right hand act like a much more useful tentacle to wrap that insulation around those tubes, and my wrist is complaining fiercely today. I was trying to make my hand twist and turn in ways that God didn't design it to do, apparently. So I figured it would be best to not stress it out more quite yet. Tomorrow will be another day...

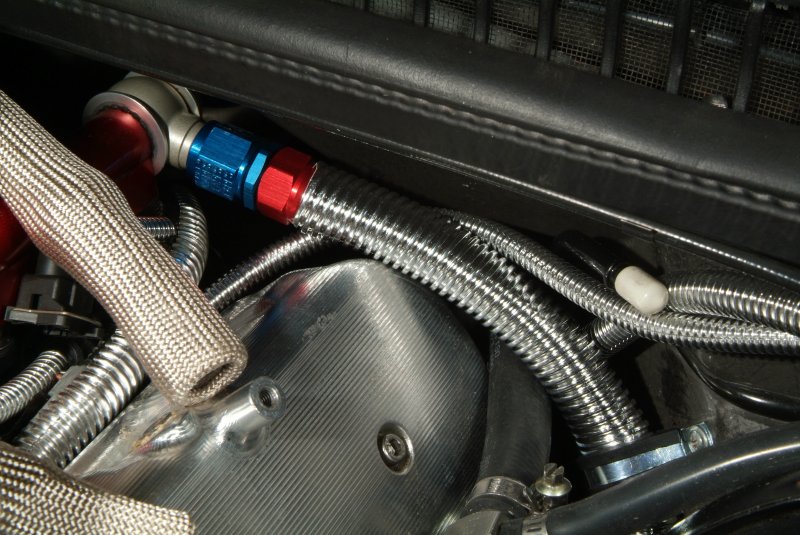

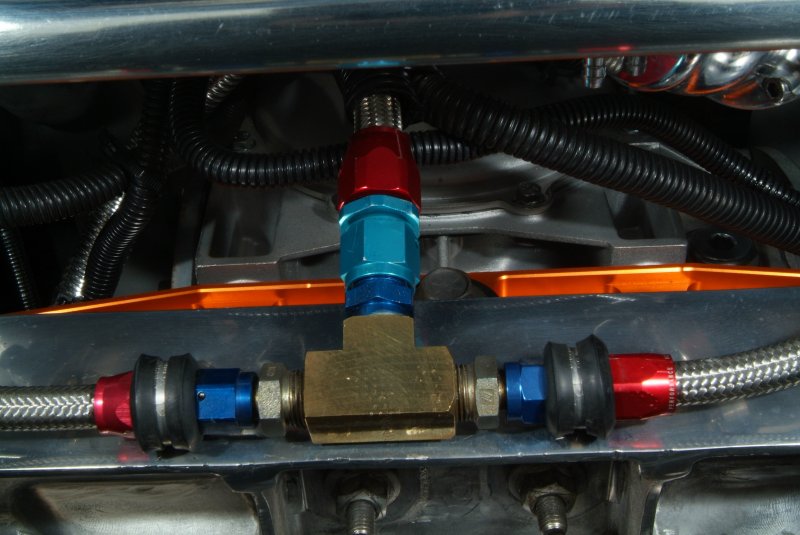

Planning on putting together those PTFE fuel lines up front and it will be easier getting to the one going from the fuel rail to the pressure regulator without the ignition wires being in the way.

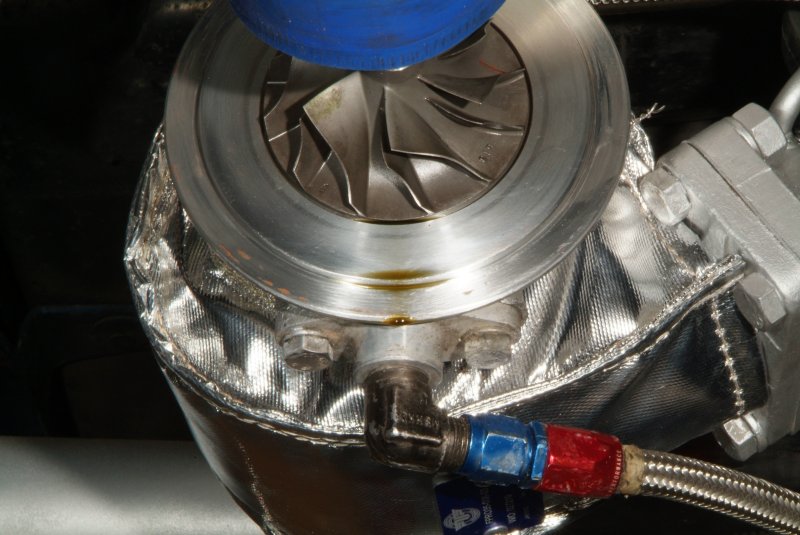

I still don't have the turbo back together as it is still slowly dripping oil. Haven't heard a word back from Turbo Direct about this, but no big deal as I think I know the cause now anyway. May pull off the compressor housing on the other turbo, since possibly that one has oil in it as well.

Hope this wrist feels better tomorrow. Want to got the car back together and drive it to try to figure out what that drivetrain noise is all about.

I can't really say that I would want to have to do this again any time soon. :nonod:

I noticed that a few of the cool socks I had on the ignition wires got heat damaged by apparently laying against the headers, so I had to order a new set of them.

Looks like the heat just bleached the black color out of those socks, but that area is also noticeably softer to the touch, so I'm guessing they are shot once that happens.

Not sure why I chose black cool socks, but this time around I got light colored ones, thinking they would be better at reflecting heat anyway. The black ones were also only 6 inches long, and it looks like 8 inch ones will cover more of the ignition wires and boots.

Also accidentally pulled off one of the ends of one of the ignition wires when trying to get them off of the spark plugs. Luckily I have a couple of extras that were on the car when it was pulled into Chris Harwood's shop, as those Granatelli ignition wires aren't cheap, and I really wouldn't want to have to buy another set of them just to replace that one wire. Maybe I can fix the broken one......... :shrug01:

I didn't do anything at all today on the car. I think I tried way too hard yesterday to try to make my right hand act like a much more useful tentacle to wrap that insulation around those tubes, and my wrist is complaining fiercely today. I was trying to make my hand twist and turn in ways that God didn't design it to do, apparently. So I figured it would be best to not stress it out more quite yet. Tomorrow will be another day...

Planning on putting together those PTFE fuel lines up front and it will be easier getting to the one going from the fuel rail to the pressure regulator without the ignition wires being in the way.

I still don't have the turbo back together as it is still slowly dripping oil. Haven't heard a word back from Turbo Direct about this, but no big deal as I think I know the cause now anyway. May pull off the compressor housing on the other turbo, since possibly that one has oil in it as well.

Hope this wrist feels better tomorrow. Want to got the car back together and drive it to try to figure out what that drivetrain noise is all about.