Yesterday I put together the wiring for the LC-1 wideband controller. Soldered a power plug to go into the cigarette lighter socket and attached the calibration button and LED. Then I went through the calibration procedures for the controller and the sensor. Everything went OK, so apparently I soldered the wires together correctly. I found a guy selling a single cable that runs from the LC-1 to the EFILive FlashScan V2 module. With the stock parts it would take two cables and a null modem adapter plugged between them, and that's just too many connections for my tastes. A single cable just makes a whole lot more sense to me. But it's not here yet so I may hold off mounting the wideband sensor into the exhaust until it shows up.

Got the stuff in from SummitRacing to replace the long runs of fuel lines going from the engine compartment to the fuel pump area. Minus one fitting that is on backorder until the end of the month, however. So I'm not pulling anything apart till I have everything I need in my hands.

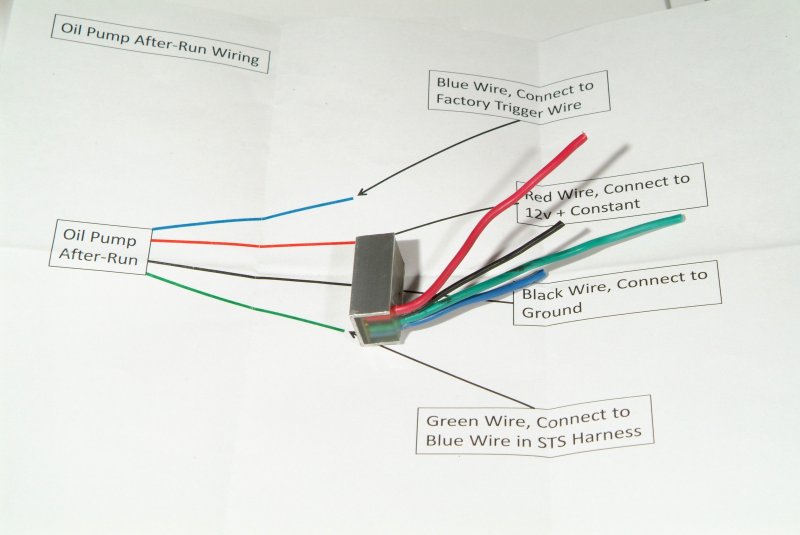

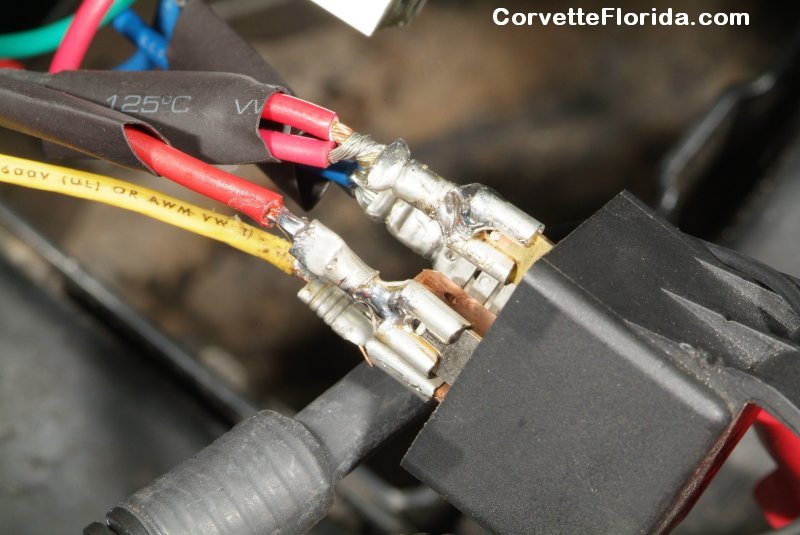

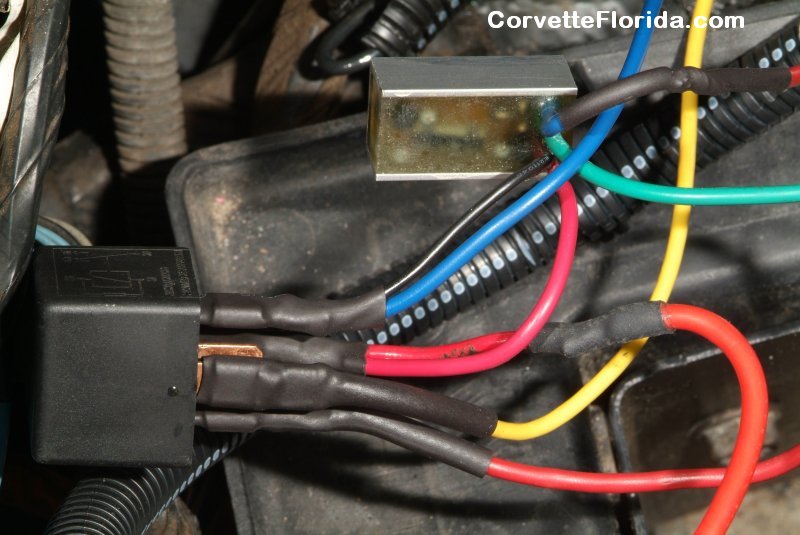

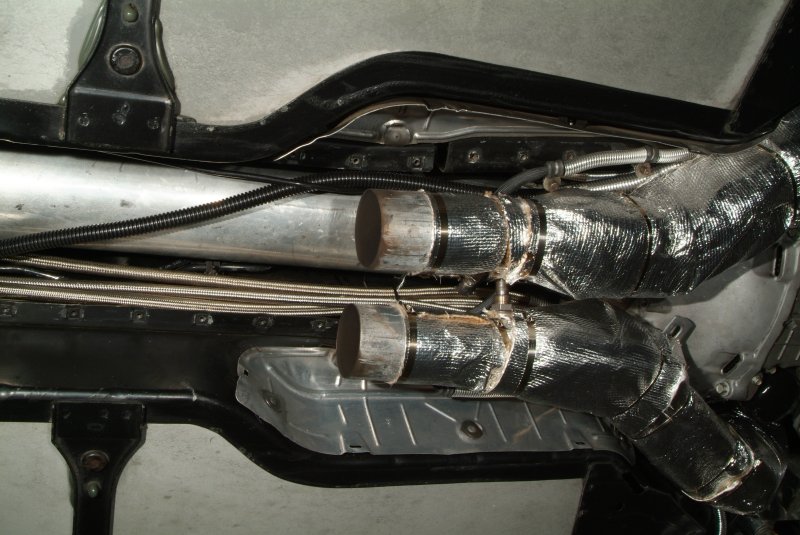

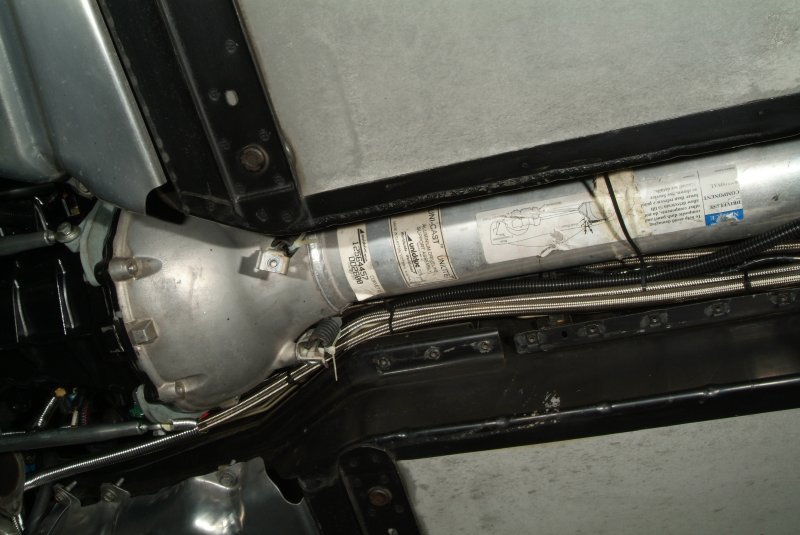

And today I got a package from STS which I presume has the turbo timer inside.

Still spending a lot of time over on the EFILive forum and reading over their tutorials. I need to figure out an make up some sort of glossary of acronyms they all use there. I already know some of them, but man it really slows down the comprehension of what they are talking about when you don't know what that acronym they are referring to means.

Mike Carnahan sent me a new tune, but I haven't flashed it into the PCM yet. I've been using his tune to look at to apply these practical examples to what the EFILive tutorials and threads are talking about. To be honest, there are some things in the tune that I just don't understand yet. But I'm still chipping away at it.

Not sure if I'm just not feeling all that ambitious because of the holiday season or if I'm being smart and just waiting till EVERYTHING shows up and I can dive in and get it all done at one swell foop. Yeah, I'm being smart. THAT's the ticket........... :hehehe: Now, where are those Christmas cookies?

Got the stuff in from SummitRacing to replace the long runs of fuel lines going from the engine compartment to the fuel pump area. Minus one fitting that is on backorder until the end of the month, however. So I'm not pulling anything apart till I have everything I need in my hands.

And today I got a package from STS which I presume has the turbo timer inside.

Still spending a lot of time over on the EFILive forum and reading over their tutorials. I need to figure out an make up some sort of glossary of acronyms they all use there. I already know some of them, but man it really slows down the comprehension of what they are talking about when you don't know what that acronym they are referring to means.

Mike Carnahan sent me a new tune, but I haven't flashed it into the PCM yet. I've been using his tune to look at to apply these practical examples to what the EFILive tutorials and threads are talking about. To be honest, there are some things in the tune that I just don't understand yet. But I'm still chipping away at it.

Not sure if I'm just not feeling all that ambitious because of the holiday season or if I'm being smart and just waiting till EVERYTHING shows up and I can dive in and get it all done at one swell foop. Yeah, I'm being smart. THAT's the ticket........... :hehehe: Now, where are those Christmas cookies?