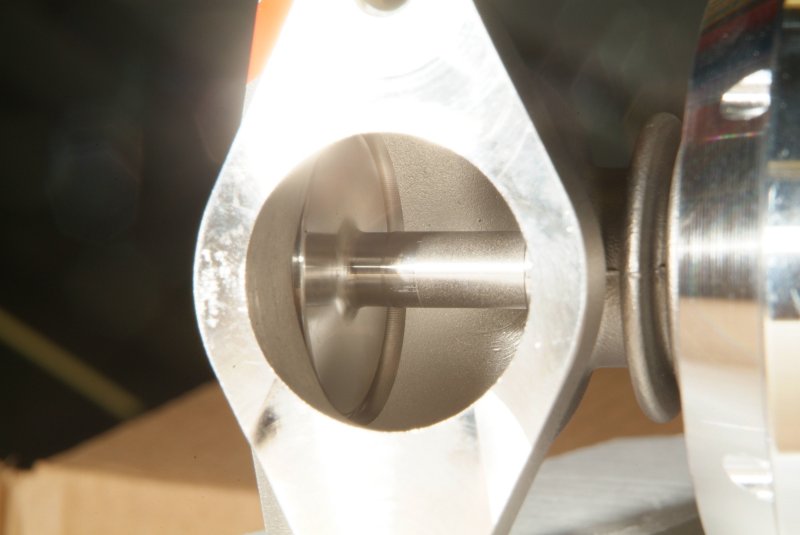

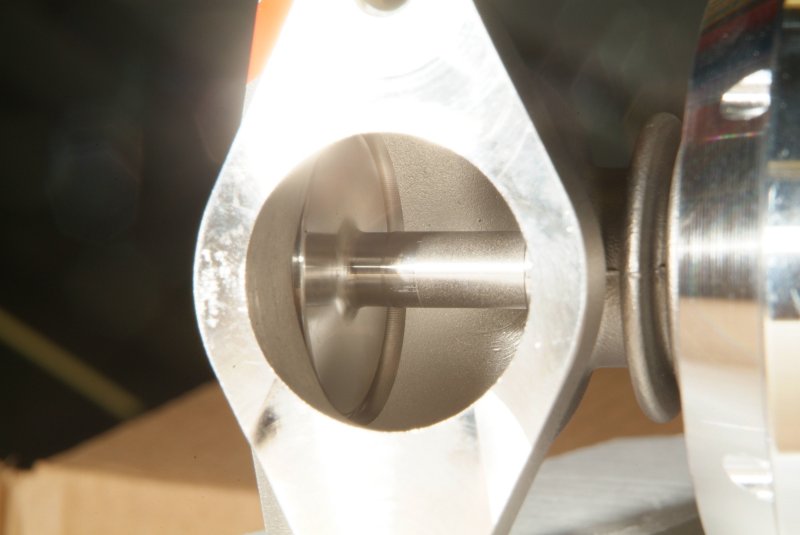

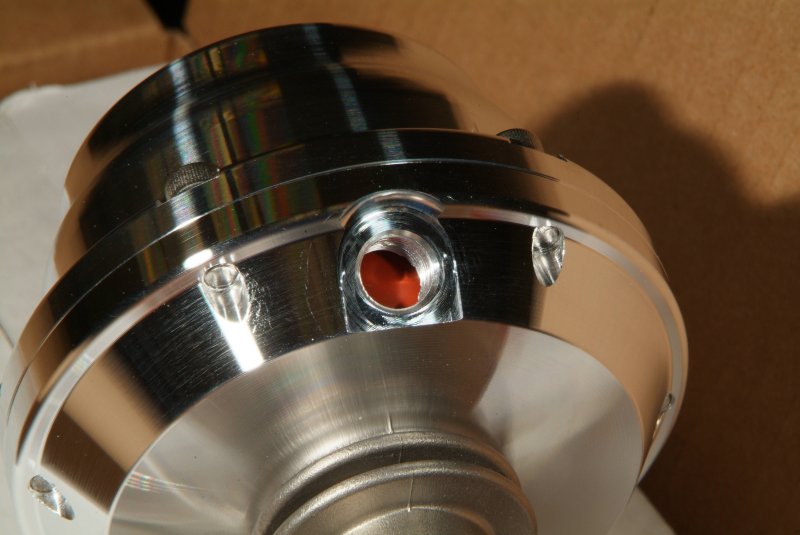

Figured I would take some pics of one of the new Tial wastegates that came in.

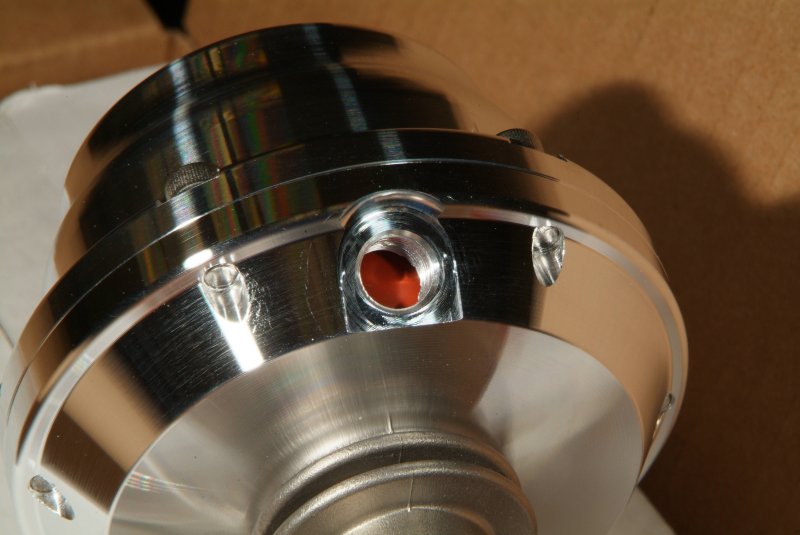

The last one shows how close the diaphragm comes to the hole for the pressure fitting coming from the turbo. I bought some banjo bolts that were too long, so I figured I would try my hand on my little Emco-Maier lathe to try to cut off 0.155 inches. Sheesh, THAT didn't go well. Been YEARS since I've played with that lathe, and I couldn't remember much about the tooling. Completely forgot about using the tailstock center so the bolt came loose and got the head boogered up. Plus I'm obviously doing something wrong as I can't get the tool head to line up the cutting edge with the center of the chuck.

Anyway, I was looking at Summit Racing's website again figuring I had better order a few more of those banjo bolts because it might take me a couple of tries to get that cut done right. Well, long story short, Earl's makes a shorter banjo bolt, but Summit's site just doesn't show any length data for them, so my guess as to which one I needed was just wrong. So hopefully the new ones I ordered will be the correct size. I also found out that Fragola has .3AN SS hoses with a -3AN end and a banjo fitting on the other so I might not have to have an extra fitting connection. I think these are all brake lines, but they should do the trick to just provide pressurized air from the compressor housing to the wastegate.

One other thing I need to figure out is how to properly drill and tap a 1/8 NPT hole into the turbo compressor housings. Evidently this is a tapered fitting, so I can't just run the tap all the way through the hole. Maybe I should practice on something else before I booger up a housing...... In any event, I'm thinking that with it being a tapered threaded hole, I might be able to control the direction I want that fitting to face by being careful about how far I run the tap into the hole. I want to use a 90 degree 1/8 NPT to -3AN fitting and it sure would be nice if I could get the fitting to face towards the waste gate. I guess this sort of thing is why good machinists earn the big bucks.

In any event, I'm thinking that with it being a tapered threaded hole, I might be able to control the direction I want that fitting to face by being careful about how far I run the tap into the hole. I want to use a 90 degree 1/8 NPT to -3AN fitting and it sure would be nice if I could get the fitting to face towards the waste gate. I guess this sort of thing is why good machinists earn the big bucks.

The last one shows how close the diaphragm comes to the hole for the pressure fitting coming from the turbo. I bought some banjo bolts that were too long, so I figured I would try my hand on my little Emco-Maier lathe to try to cut off 0.155 inches. Sheesh, THAT didn't go well. Been YEARS since I've played with that lathe, and I couldn't remember much about the tooling. Completely forgot about using the tailstock center so the bolt came loose and got the head boogered up. Plus I'm obviously doing something wrong as I can't get the tool head to line up the cutting edge with the center of the chuck.

Anyway, I was looking at Summit Racing's website again figuring I had better order a few more of those banjo bolts because it might take me a couple of tries to get that cut done right. Well, long story short, Earl's makes a shorter banjo bolt, but Summit's site just doesn't show any length data for them, so my guess as to which one I needed was just wrong. So hopefully the new ones I ordered will be the correct size. I also found out that Fragola has .3AN SS hoses with a -3AN end and a banjo fitting on the other so I might not have to have an extra fitting connection. I think these are all brake lines, but they should do the trick to just provide pressurized air from the compressor housing to the wastegate.

One other thing I need to figure out is how to properly drill and tap a 1/8 NPT hole into the turbo compressor housings. Evidently this is a tapered fitting, so I can't just run the tap all the way through the hole. Maybe I should practice on something else before I booger up a housing......