Rich,

Why not just get a cheap hand siphon pump and pump the gas out from the filler opening?

Back in the days when I was still in Maryland, and before I decided to heat my garage, I used to use a kerosene heater to take the chill off in the garage. I used a battery operated hand held siphon pump to pump the kerosene out of the can and into the heater. They were not terribly expensive and moved the kerosene pretty quickly. Here is a link to one I found that was like the one I used. Pretty cheap to eliminate the aggravation that you are going through.

http://www.heartlandamerica.com/browse/item.asp?PIN=48043&DL=GAW1&SC=WIG20001&

I am sure if you went to a Northern Tool or Harbor Freight store in your area, you could find something to siphon the gas out from the filler opening.

Good luck.

Rich

Actually I read somewhere that someone said that you can't get a siphon tube down the neck of the gas filler tube because of some sort of obstruction that may be there specifically to block this. At least that's what I remember trying to research this problem online. I actually have a siphon pump that I bought a while back and was going to try it but the bulb that you are supposed to squeeze to get the siphon action working is hard as a darn rock. I don't know if it's from the rubber bulb hardening with age or I've just become much more feeble in my old age than I realize. I believe I bought that and the pump thing I tried yesterday both from Harbor Freight. I bought them a few years ago to keep in my "emergency rations" kit.

I did a scan on Google for some sort of siphon pump, but all I could find were things that were either no better than what I already have, or else big commercial units for shops that were way too expensive for this single job.

I did read an account where someone actually punched holes into the bottom of his gas tank to drain it, then sealed it back up with JB Weld or something. I don't think I'm at the point to do something as drastic as that, but obviously the guy wasn't having much luck coming up with a more elegant solution neither.

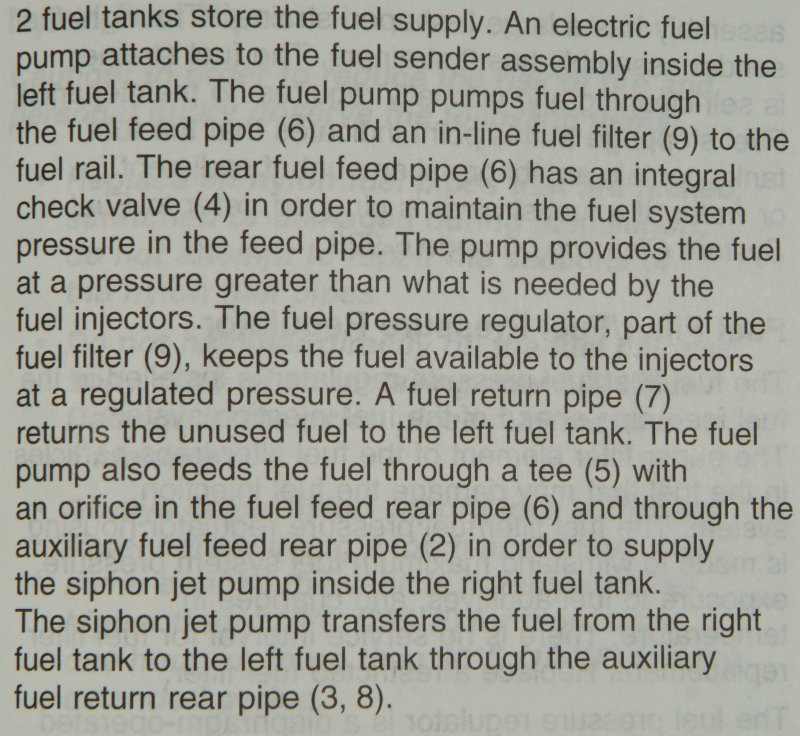

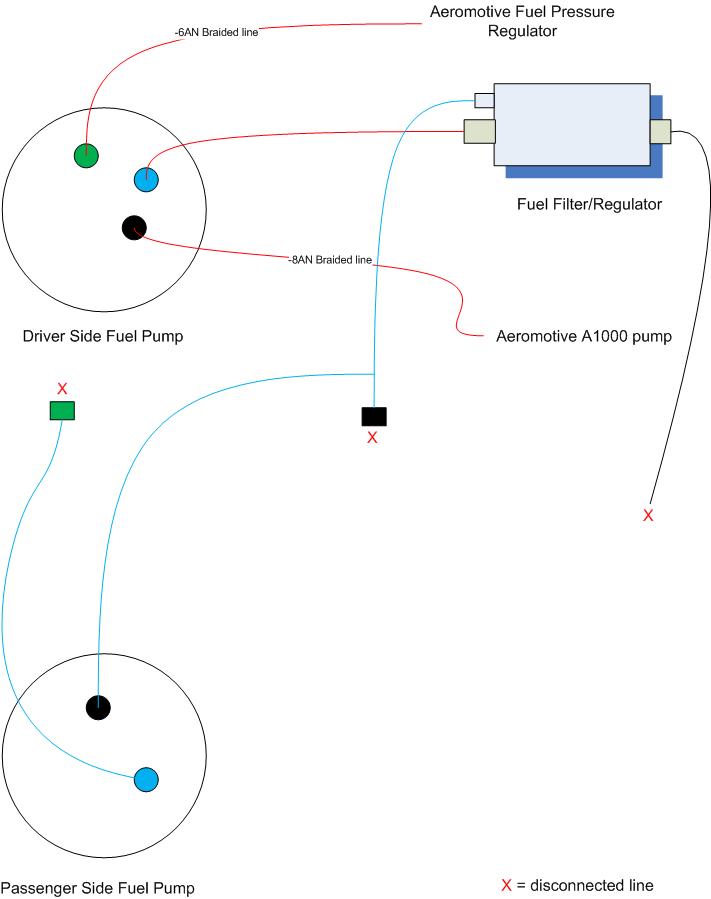

I really thought the fuel pumps on the car would do the job, but apparently not. So far no one has come up with anything that I have overlooked trying it that way, so I guess I'm the first one in the world to run into this kind of problem. Lucky me.....