I got the suspension back together on the driver's side front today. New bearing/hub, rotor and pads. Just need to put in the new braided brake hoses and new bleeder screws, then bleed/flush the brake fluid and that should all be done.

One thing that puzzled me was that Aaron said he found two cross threaded bolts in the suspension, and I've been over every bit of the suspension and not seen any sign of that. If it was a bolt/nut cross threaded, I would have thought that either the bolt, nut, or both would have been replaced rather than rethreading them and having the threads weakened by the damage. But I don't see any signs of new hardware anywhere in the suspension. Heck, I pulled out many of the bolts during the stuff I was doing and ran them through a die to clean out the original sealant still on them before putting them back in. :shrug01: Heck, I dunno. Maybe they just happened to be two bolts I DIDN'T look at somewhere.

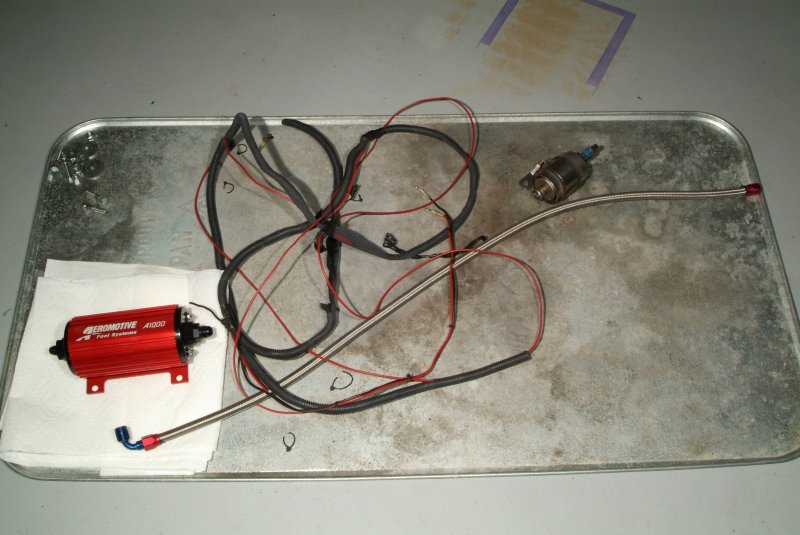

The fuel pump was shipped to Lonnie's Performance on Thursday, and Jon at FIC said that he shipped out the new injectors today for me.

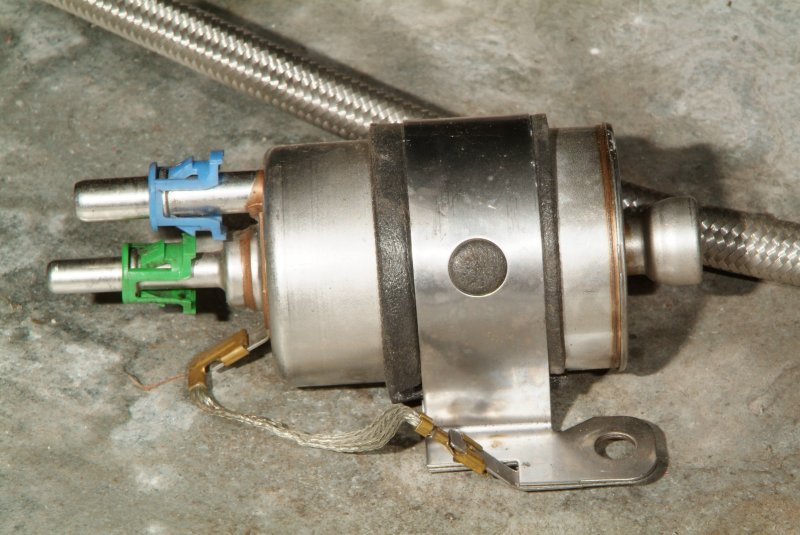

I guess in the meantime I may go ahead and get a new fuel pressure regulator rather than worrying about it being screwed up with metal particles inside, and try to figure out what to do about the vacuum plumbing. But it may be best to just wait to see what I need when the new fuel pump comes back. And by then maybe I'll have some idea of whether or not I'll be putting that 2 bar MAP sensor in.

One thing that puzzled me was that Aaron said he found two cross threaded bolts in the suspension, and I've been over every bit of the suspension and not seen any sign of that. If it was a bolt/nut cross threaded, I would have thought that either the bolt, nut, or both would have been replaced rather than rethreading them and having the threads weakened by the damage. But I don't see any signs of new hardware anywhere in the suspension. Heck, I pulled out many of the bolts during the stuff I was doing and ran them through a die to clean out the original sealant still on them before putting them back in. :shrug01: Heck, I dunno. Maybe they just happened to be two bolts I DIDN'T look at somewhere.

The fuel pump was shipped to Lonnie's Performance on Thursday, and Jon at FIC said that he shipped out the new injectors today for me.

I guess in the meantime I may go ahead and get a new fuel pressure regulator rather than worrying about it being screwed up with metal particles inside, and try to figure out what to do about the vacuum plumbing. But it may be best to just wait to see what I need when the new fuel pump comes back. And by then maybe I'll have some idea of whether or not I'll be putting that 2 bar MAP sensor in.