Didn't really do much today. Connie and I had to run up into Tallahassee to do some errands, and I didn't feel like drilling into the car and trying to mount relays and fuse holders.

So I decided to take a look at the wiring for the STS oil scavenge pump to see if I could figure that out and get it back to the way it should be. Meaning that I want it to run much like the fuel pump and ONLY be on when the engine is running. So I decided to start where I think the problem has to be at. The relay.

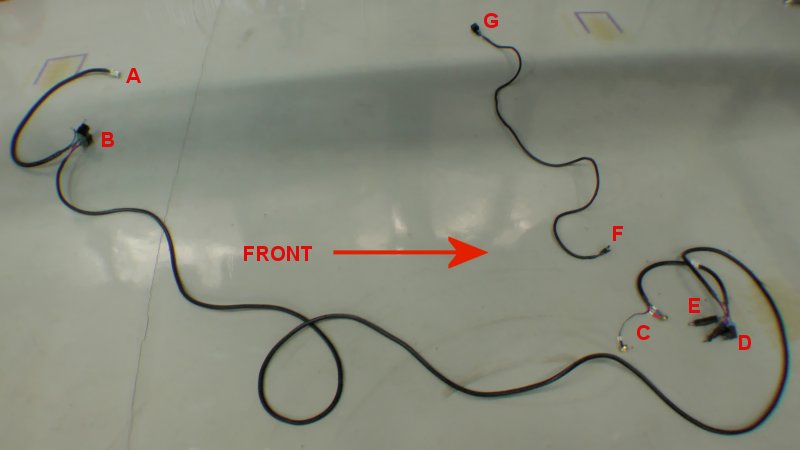

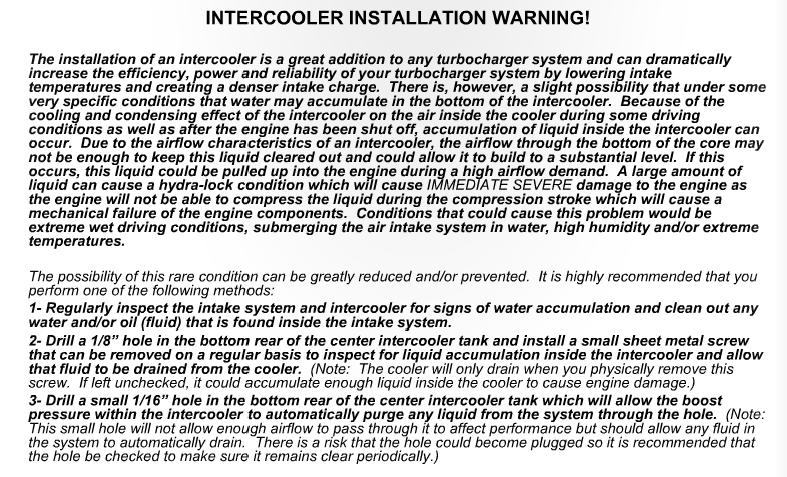

I traced the wires and here's what I came up with.

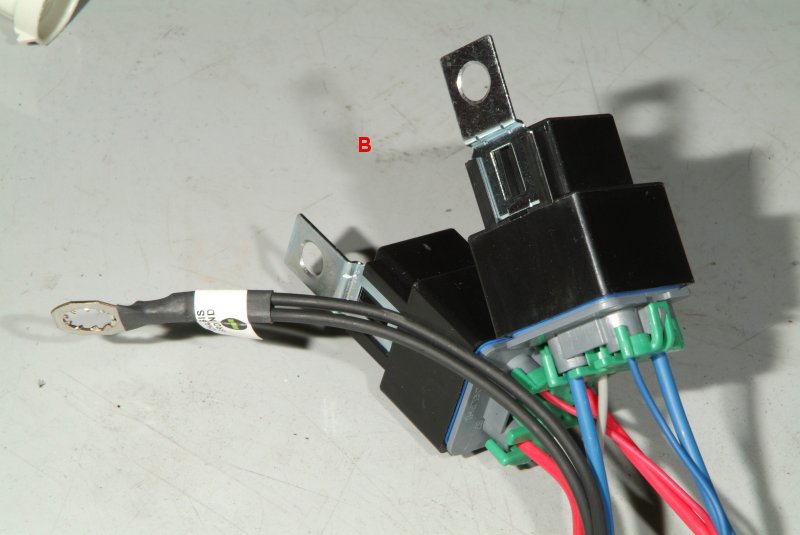

- The RED WIRE runs to the top of the fuse block and plugs into a fuse socket. This is the wire I would pull when I wanted to shut off the scavenge pump when I needed the ignition switch to be on.

- The wire with the convoluted tubing on it is also a RED WIRE and that one goes to the + side battery connection that provides power directly to the fuse block itself. This has an inline 15 amp fuse on it.

- The BLUE WIRE runs to frame ground.

- The YELLOW WIRE runs to the + terminal of the oil scavenge pump.

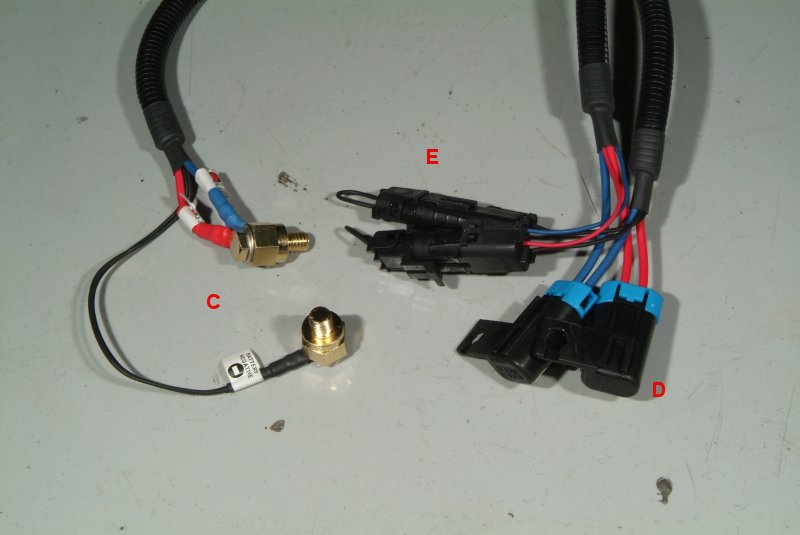

I opened up the wiring harness that the yellow and blue wire run into, and found a white wire and black wire that had been cut off there. As best I can tell, these cut wires go to the oil pressure switch at the scavenge pump and I believe were originally hooked to an alarm to alert when something went wrong with the scavenge pump and no oil pressure detected coming back from the turbos.

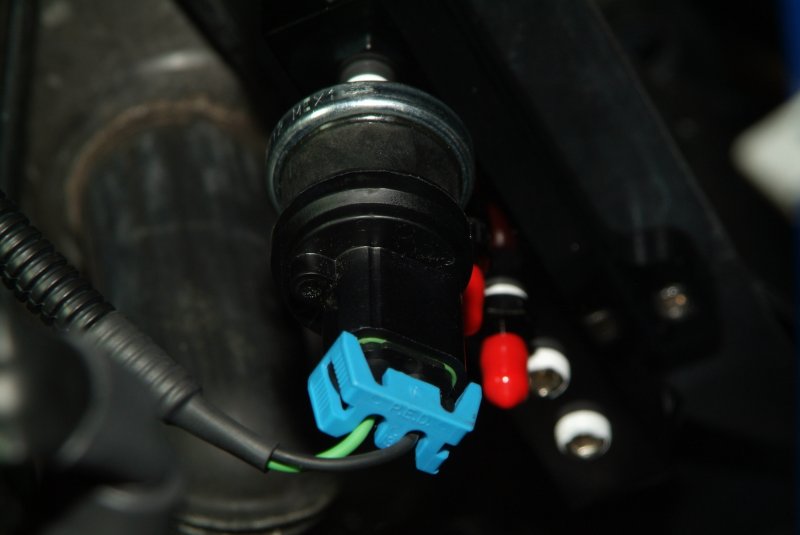

Here's the yellow and black wire at the top of the scavenge pump.

And here are the white and black wires running to the oil pressure sensor.

I think what is going on is that the red wire running to the top of the fuse block is the problem. It is providing constant power to the relay when the ignition switch is turned on. The STS manual mentions something about tapping into one of the power wires running to the fuel injectors, as apparently they operate like the power line running to the fuel pump. When the ignition is turned on and the engine isn't started, power shuts down to the injectors after 2 seconds. So I think all I need to do is to tap into one of those injector power wires and run that wire over to the relay to replace that red wire.

Anyway, when I cracked open the STS manual, the first pic I see is of one of the turbo wastegates. There is a bolded notice there stating

The Rear Vent Port on the wastegate must be vented to atmosphere.

Hmm, seemed to me that I recall looking at the wastegates on my car and they didn't appear to have those ports open. So I went over and checked them out.

Double hmmm.....

The manual doesn't really say anything about what would happen if they are NOT vented to atmosphere, but it does say that applying boost pressure to that Rear Vent Port and/or not applying boost pressure to the Front Boost Port will cause the wastegate to stay closed and the turbo to over-boost.

This will cause IMMEDIATE SEVERE damage to the vehicle's engine!

Sheesh.... Great....

I sent STS an email to get their take on this situation. Might be a darn good thing I didn't get heavy with the GO pedal driving the car home back in November.

I did trace the vacuum lines from the Front Boost Port of both wastegates and they do appear to be connected to a vacuum port on the back of the intake manifold. I had to use a flexible inspection camera in order to check that out. Oh yeah, I got to see that MAP sensor back there too...

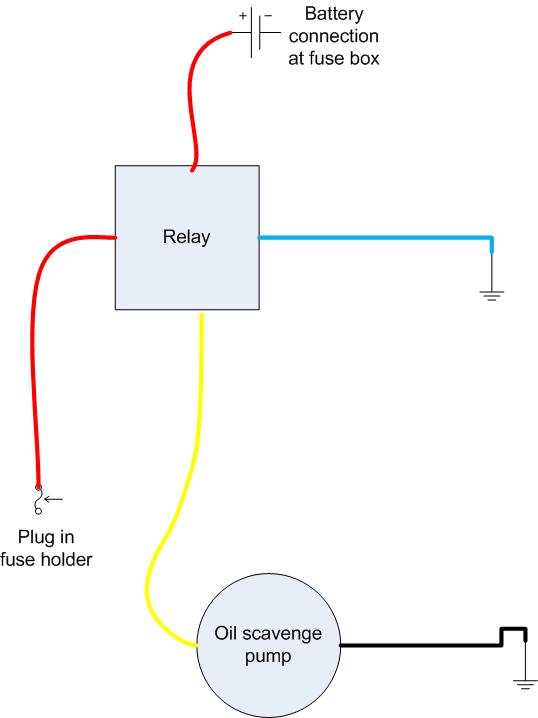

So I was leafing through the STS manual while eating dinner, and this notice caught my eye.

Unfortunately it doesn't tell me HOW to inspect the intercooler. Why would this concern me? Well, I was told by Aaron three times while he had my car that the air intake piping had inadvertently been exposed to oil because of one reason or another. So he cleaned the oil out by somehow washing out the plumbing each time. That is three times that I am aware of that fluids have been in the intake, meaning quite likely into the intercooler, of the STS system.

I would hope that the intercooler was flushed and dried out properly each time, or at the very least any water or cleaning fluid in there would have evaporated over the last few months, but heck, do I really want to take that chance? Suppose there is still oil in that intercooler? I know when I was cleaning up underneath the car recently that there were signs of oil having come out of the blow off valve attached to the bottom of the intercooler.

So yeah, looking through the STS manual has just been chock full of fun today...