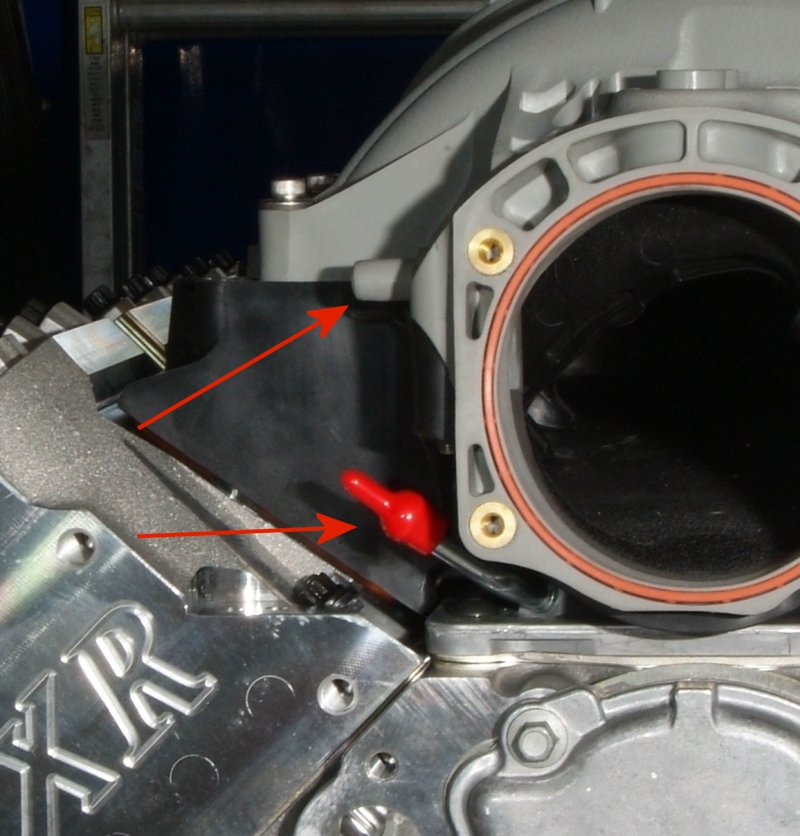

Decided to work on the vacuum plumbing today (Saturday), and the first thing I did was to pull off that vacuum hose going to the brake booster check valve. Uh oh... Here I was thinking this was a 3/8ths ID hose, and it's a 1/2 inch ID line. Rats... Of course I didn't have a "T" fitting for that size hose, but up to my eyeballs in all kinds of 3/8ths fittings. Not only that, but I needed a "T" fitting with the two straight sides being 1/2 inch, and the bottom part being 3/8ths inch to run to the vacuum manifold block. Sheesh, I thought there was just no way in hell I was going to be able to find something like that. I searched around on the net and found a couple of sources after a lot of digging, but was pretty darn surprised when I discovered that Home Depot carried exactly what I wanted. Was even made out of brass. So I called over there with their part number, and was amazed to find that they actually had one in stock. Will wonders never cease. So Connie and I drove on out there to pick it up. On a whim I also picked up a 90 degree elbow 1/2 inch fitting as well, as I didn't like that sharp bend in the rubber hose going to the check valve, and I thought this might be a better solution.

Well, after cutting up that check valve hose and putting in the fittings, I decided I just don't really like the way it looks with all those clamps there by the booster. I didn't realize it was a molded hose, and thought it was just a standard hose bent at that sharp 90 degree angle. So there are two clamped hose connections more than I really like there. It will work, but I'm going to try to locate a new molded hose and just use the end from the check valve to where I put that "T" fitting in place. Duh.... Live and learn, I guess... Seemed like a good idea at the time, though.

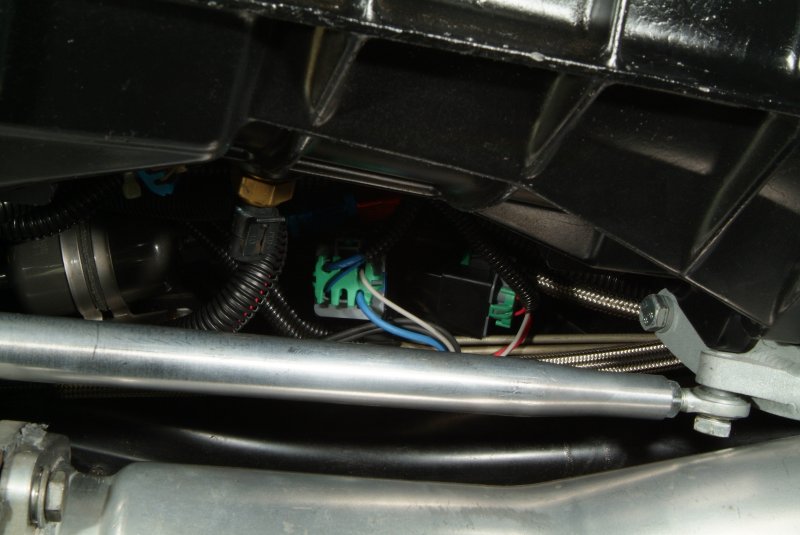

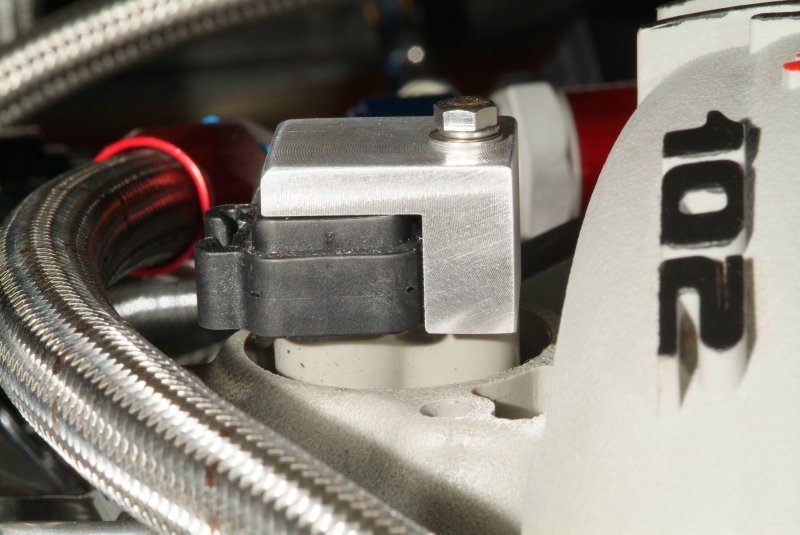

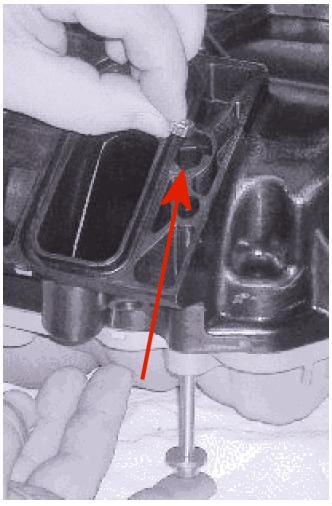

Anyway, got the hose ran from the brake booster "T" to the vacuum manifold block, and just had to add a short section of additional hose to get the hose from the blow off valve to reach the vacuum manifold. But I'm going to take another look at that one, as I'll explain. I was trying to get a short length of hose to run from the fuel pressure regulator to the vacuum manifold using these fittings I got from Oomph Labs called "Hose Candy". The idea seemed good to me, as I wanted to be able to easily take off that hose in case I needed to fiddle with adjusting the fuel pressure regulator at anytime in the future. Since you should really adjust the fuel pressure with the vacuum hose OFF, I figured an easy way to do that might be advantageous. But I must have been doing something wrong, because although the ends that screw together seem solid enough, the ends that actually fit into the hoses and rubber adapter on the vacuum manifold fitting just came apart way to easily for my comfort. If I can pull a hose fitting apart with just a modest amount of tugging, then I really don't feel comfortable that the hose will stay in place when 10 psi of boost is running through it. So I need to check that hose fitting on the blow off valve, as I used a "Hose Candy" fitting there as well. Yeah, I guess I could but wire ties or hose clamps on those ends, but then, did I really make things all that much easier on myself?

Anyway, I just attached one end of the vacuum hose on the fuel pressure regulator and left the other end open, as I need to adjust the pressure down to 55 psi (it is now set at 58 psi) with the vacuum line open to atmosphere. I couldn't do that today, as I am planning on pulling off the passenger side fuel rail tomorrow so I can get to that stock MAP sensor wiring harness to disconnect it. I wanted pressure to be bled off of the fuel lines as much as possible so I wouldn't have gasoline spraying all over the place when I disconnected the fuel rail.

So tomorrow the game plan is to:

- pull off the passenger side fuel rail,

- disconnect the stock MAP sensor harness connector (hopefully without too much cussing),

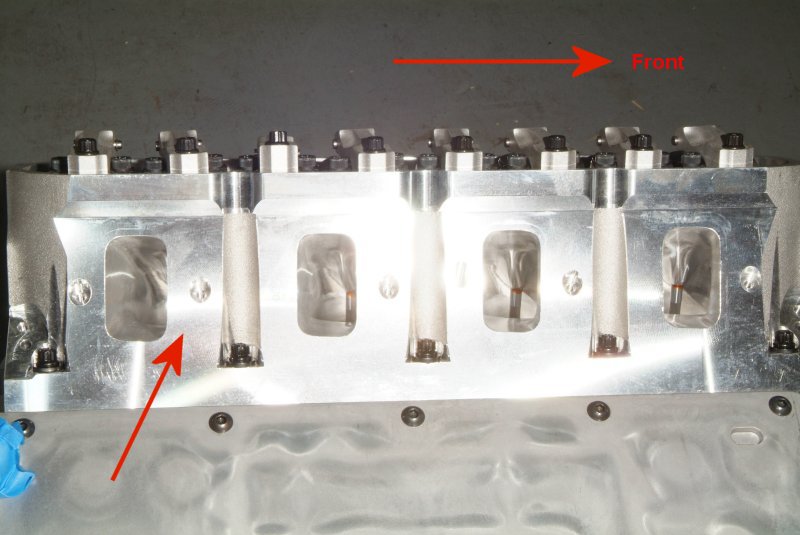

- install the MAP sensor harness extension to the 2 bar MAP sensor now at the front of the intake manifold,

- put the passenger side fuel rail back on.

- run up the pressure on the fuel pumps and check for leaks again,

- adjust the fuel pressure regulator to 55 psi,

- put the fuel pressure regulator vacuum hose onto the vacuum manifold block,

- try to think of anything I might be overlooking that needs to be done.

If that all goes well, all of the hardware stuff is

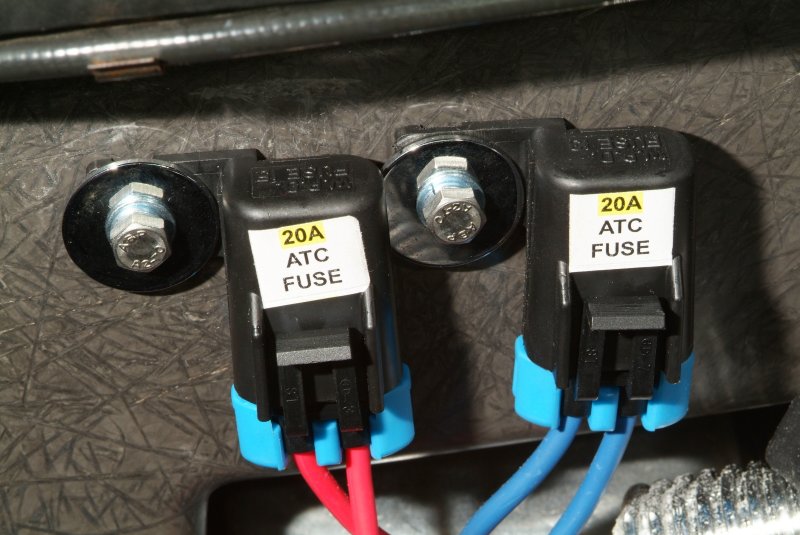

done, I think. Just some minor cleanup to do, like shorten that fuel pump harness, put some access panels back on the car, and put the wheels back on.

Oh yeah, need to figure out that wideband controller and how to get HPtuners ready for that custom operating system that is needed for the 2 bar MAP tune. But hopefully Ed will give me detailing instructions on how to do that.

Only got a 1/4 tank of gasoline in the car, and I'm hoping I'll be able to drive it to the gas station when I want to put more in it..... Trying to hold that 5 gallon gas tank to pour it into the car's gas tank was about to throw my back out of whack. :ack2: