Fantastic news. Want to REALLY know what's in your oil? For $25 you can find out via Blackstone Labs. I still need to send mine in from my last oil change. Just fill out the form and you'll get the test kit in about a week.

I may try that.

Thanks!

Fantastic news. Want to REALLY know what's in your oil? For $25 you can find out via Blackstone Labs. I still need to send mine in from my last oil change. Just fill out the form and you'll get the test kit in about a week.

Hi Rich, Glad to see you finally got your car back. Sounds like Shane did a great job getting it fixed. Now maybe we can go to Silver Springs in Nov. I get my car back this Thursday. So far no reduced power the past 2 weeks of Clint driving it every day. Maybe our saga is finally over!!!

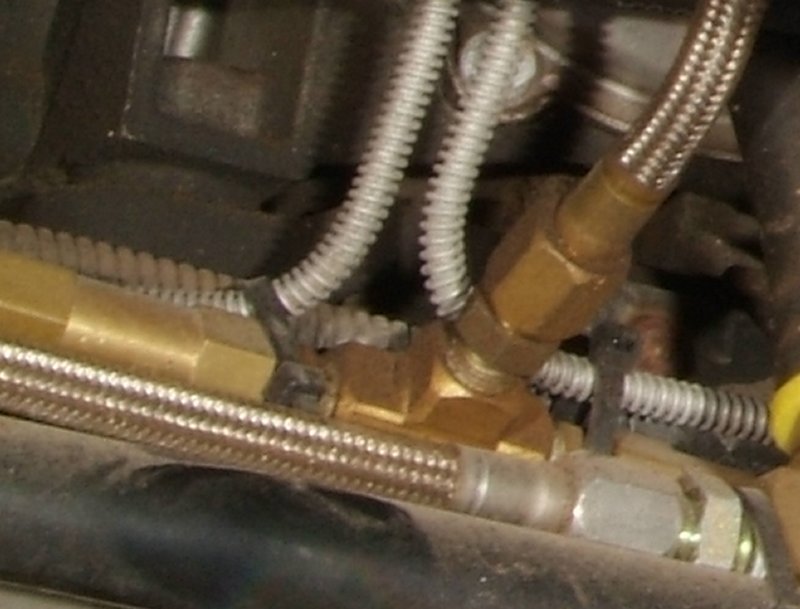

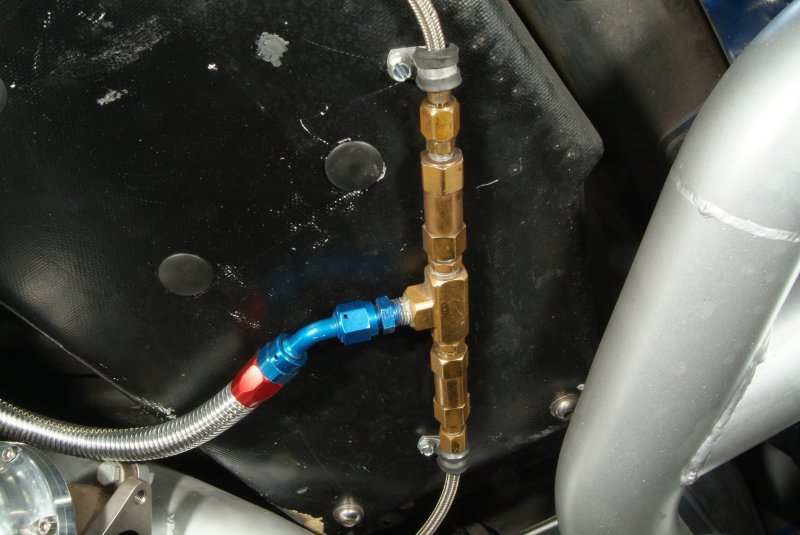

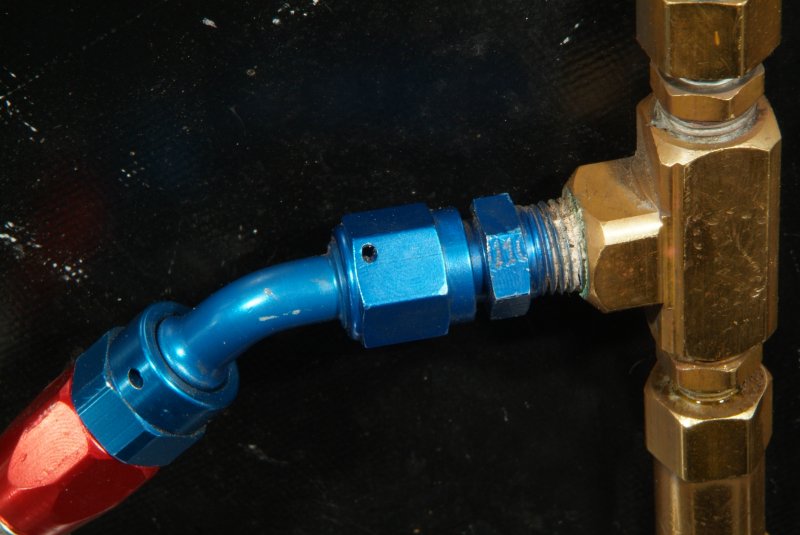

If everything is working and it were mine I would just drive it for 6 months. What's the old saying if it ain't broke don't break it. Those fitting in brass look like they came from someplace like Lowe's plumbing department. I know that connection does not meet your standards and I understand that but there comes a time when you have to turn the key and just enjoy the drive. My son is very particular about his vehicles and the slightest scratch and there off to the body shop. I told him one time to forget it because at 100 feet and 100 MPH nobody will see them. I don't know about Florida but here nobody has ever come up to my car and jacked it up to look at the underside.:lmao:

That's not to say if it is a poor place for those lines to be run then by all means you will have to figure something out.