No!~!! It means that it has Way,Way too much clearance,And the thumb means "That is Gospel"! :thumbsup:

I've seen Power Stroke Diesel Ford trucks with 300,000 miles and not have the clearance that one has!

My guess is that either someone didn't know what they were doing,Or it's never been rebuilt!!

With no more miles than that one is supposed to have on it you should need a dial indicator to detect any excessive movement!

:iagree::iagree::iagree:

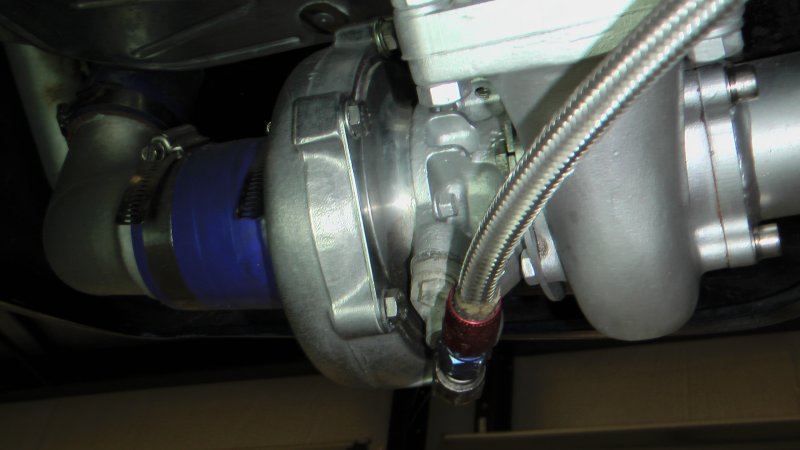

Well, I know there are different turbine housings on the turbos now than when I had the car towed to Aaron Scott's shop. But I guess you are right, that doesn't mean they were actually rebuilt with new bearings and seals. Just different housings could have been put on them. I would have to check back in this thread to see when Aaron Scott actually put those "rebuilt" turbos on my car, but I believe it was later on in the 14 months he had the car at his shop. He put a total of 400 miles on the car while he had it, and based on the tune, I seriously doubt he was able to push the engine much without getting REP failures. That wrong throttle body alone would likely have done that.

When I brought the car home the only times the engine was put into boost was a few times when Mike Carnahan was tuning it, and that one time I goosed it a little bit when I was trying to get used to the clutch and then heard that awful racket when I got off the gas and was engine braking to slow down. So those turbos really shouldn't have been stressed at all. I'm trying to think back how many miles I may have put on my car since November and I'm thinking it may be 800 or 900 miles. I think I just recently got the 500 break in miles on the new clutch, and I doubt I put more than 400 miles on it after getting the car back on the road before the drivetrain failure caused by the missing bellhousing bolts and the incorrect Pfadt driveshaft.

But that compressor housing seal being missing is a bad sign, I think, about SOMEONE's "quality" workmanship. The compressor housing mounting holes being stripped out is a bad sign concerning SOMEONE's just leaving their mistake and hoping I wouldn't have noticed it. Since that housing would have had to have been loosened to hook the turbo up to the STS plumbing, I think it's a pretty safe bet to assume that Aaron Scott stripped those bolt holes. As for the seal being missing, well, he shouldn't have had to have completely removed that housing, as far as I know, so that issue might have been from Turbos Direct. Quite honestly, based on what I later learned about Aaron Scott's attitude about me and my car, he may very well have directed Turbos Direct to just send me any old scrap, but passable, turbos they had laying around, and then charged me that $1,200 for them.

I'll be quite honest about it, from my own personal perspective based on my experiences with them and how they treated ME, I really can't see a hell of whole lot of difference between Chris Harwood and Aaron Scott. :nonod:

So, do I rebuild these turbos hoping the housings themselves are OK, or start scraping up the dough to buy new ones?