I wound up putting my old stock upper radiator support back in, as it just seemed to fit better than the blue one I had been using. Plus the paint on the blue finished one was getting kind of beat looking from what it has been though the last few years. I was able to get the radiator positioned better so that the fan shroud is now flush up against the radiator. I also lined the underside of the support with some adhesive backed insulation while I was at it to try to shield the airbridge a little bit from heat coming from the radiator beneath it.

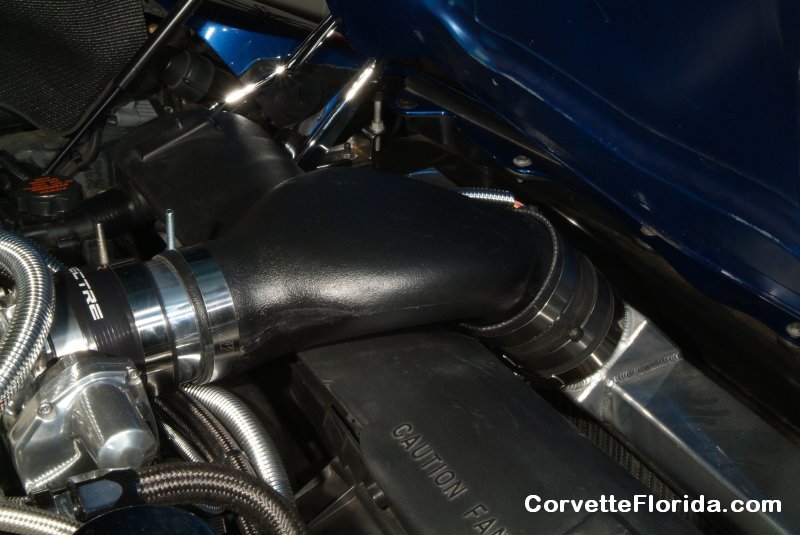

Still got some minor snags, but the airbridge went in pretty well. Connie was helping me with this step of the process. She seems to get a kick out of helping me in the garage. I was able to slide the lower end of the airbridge over the end of the MAF housing, so I didn't need to use that steel tubing, and I cut off a section of the 3.5" aluminum tube to go into the upper section and mate that to a rubber coupler to the throttle body. That rubber coupler is a 4" to 3.5" adapter, needed to mate that throttle body to the airbridge. So the aluminum tube bridges the gap between the rubber coupler and the airbridge, allowing me to get a nice secure fit with the T-bolt clamps.

As for the snags, I didn't have exactly the sizes I needed for a couple of those T-bolt clamps. Apparently they are VERY specific to the application needed, with only about three tenths of an inch leeway between the lower and upper limit to the size of connection they will work with. So you pretty much have to measure for EXACTLY the size you need. On the lower section of the airbridge I had to put a piece of rubber coupler over top of the airbridge itself to allow that clamp to seal. Then on the rubber coupling between the throttle body and the aluminum tube coming from the airbridge, the clamp I used there on the aluminum tube is bottomed out. It's snug, but I'm just not comfortable that it is TIGHT. So that means another order for Summit Racing.

While I was at it, I also ordered T-bolt clamps for as much of the rest of the STS plumbing that I could reach without taking anything apart to get to the connections. Hopefully I measured the diameters correctly. Like I said, there is very little room for guesstimating what you need with those T-bolt clamps.

Anyway, I snugged everything down, then started up the engine to allow the airbridge to get hot enough to be flexible, then cranked down the T-bolts to form the ends of the airbridge to the aluminum tube at the top, and the MAF housing on the bottom. I could FEEL the bolts tighten up, so obviously the plastic of the airbridge was pretty pliable then. When I installed the aluminum tube back into the bridge after cutting the tube to the size I needed (got to use my bandsaw, yay!), I already had to re-heat the airbridge just to get the tube back into it. So it should be pretty snug in there now, and hopefully be an airtight fit.

Also, I didn't realize how much thread would be showing on those T-bolt clamps, so I'm going to have to reposition them. Just looks goofy the way it is now with them sticking straight up into the air alongside the airbridge and couplers, but it's fixable. I figure I'll do that when I get the proper sized clamps in from Summit.

But one thing for sure, the airbridge fits a WHOLE lot better now like this. Lots of clearance between it and the hood now. I guess I can even put that hood liner in that I've had sitting in it's box for the last couple of years.