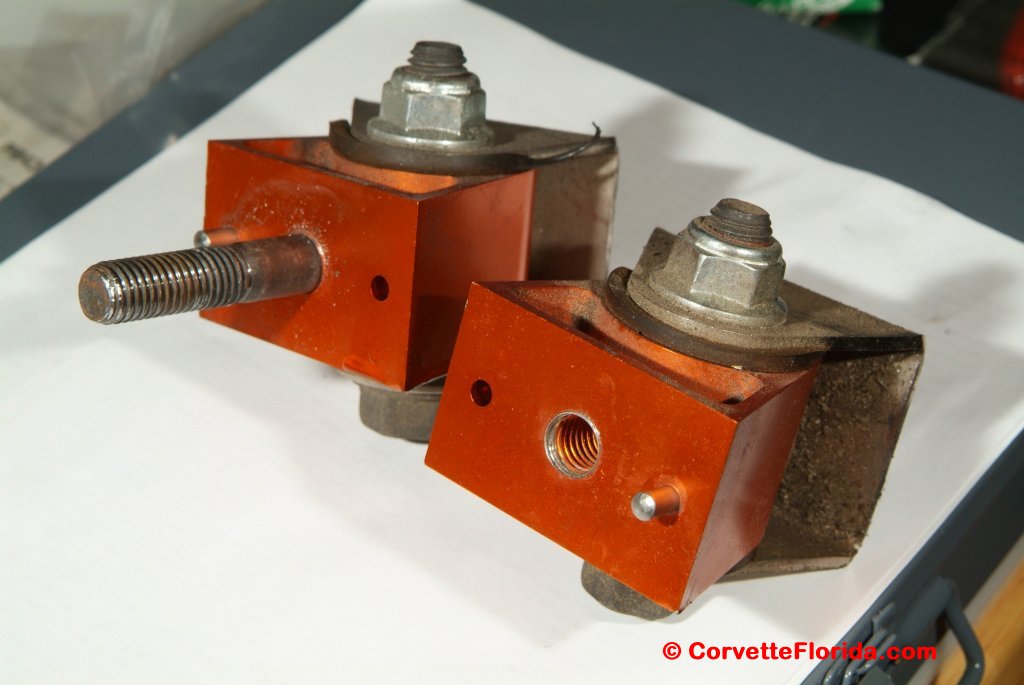

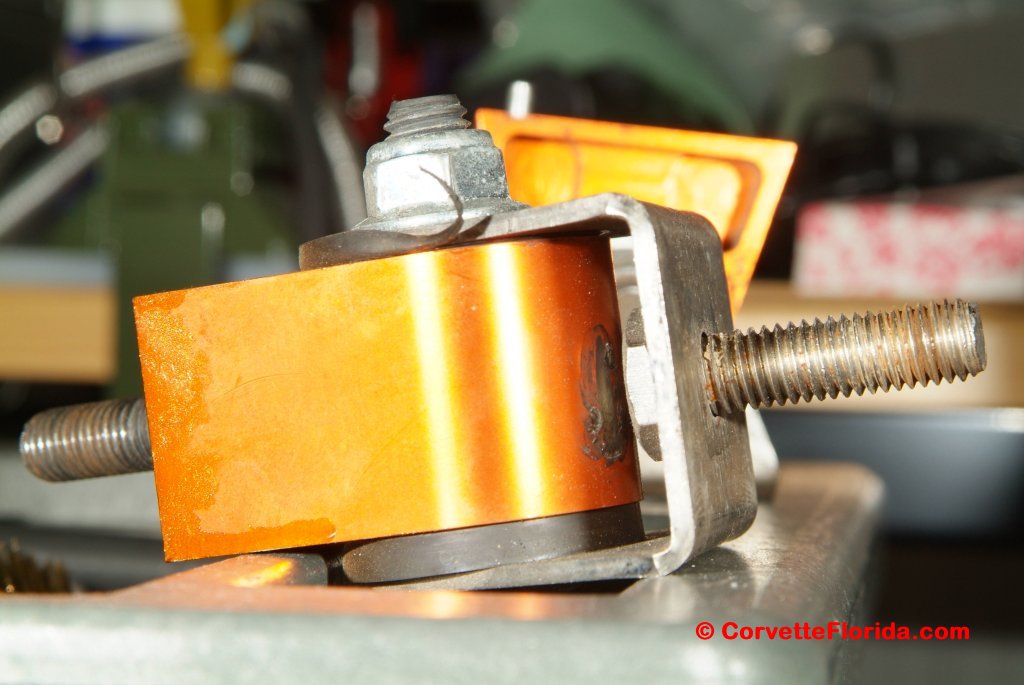

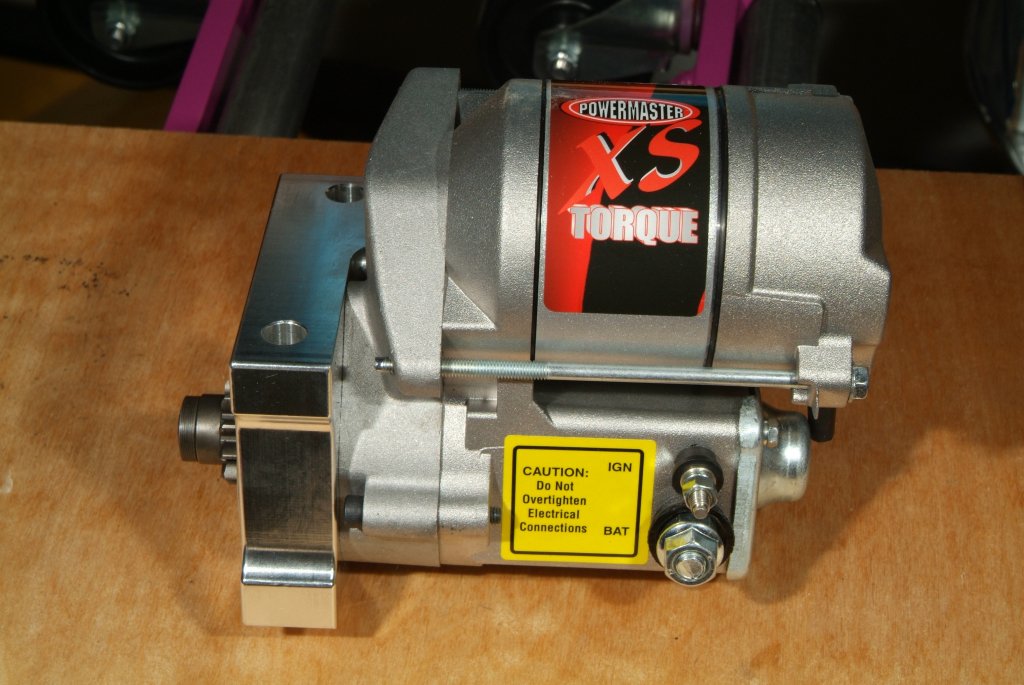

Got the starter and the new heat shield I needed after butchering the one I had for that Powermaster starter I returned.. I ordered a new flywheel dust cover because I had to butcher the one I had to fit without taking the starter out. But the people who shipped it must have thought I was kidding when I included my PO Box along with the physical address. I don't get mail delivery to the home, and you never know these days how something is going to be shipped, much less make the final leg of delivery. Sometimes something shipped via UPS or FedEx will actually go to the post office for actual delivery to the destination (me). So I include both addresses to play it safe. But since they didn't include the PO Box, it got returned to them. Oh well. Guess I use the old cover now. The starter is in, as I certainly was not going to wait for another $10 piece of plastic to show up before getting moving on this.

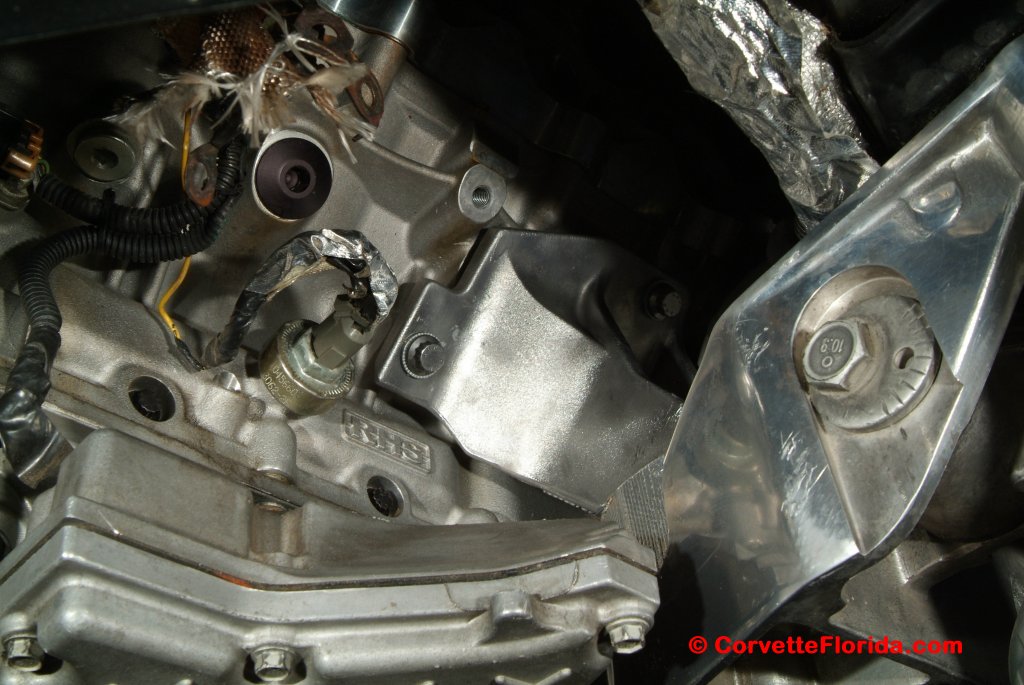

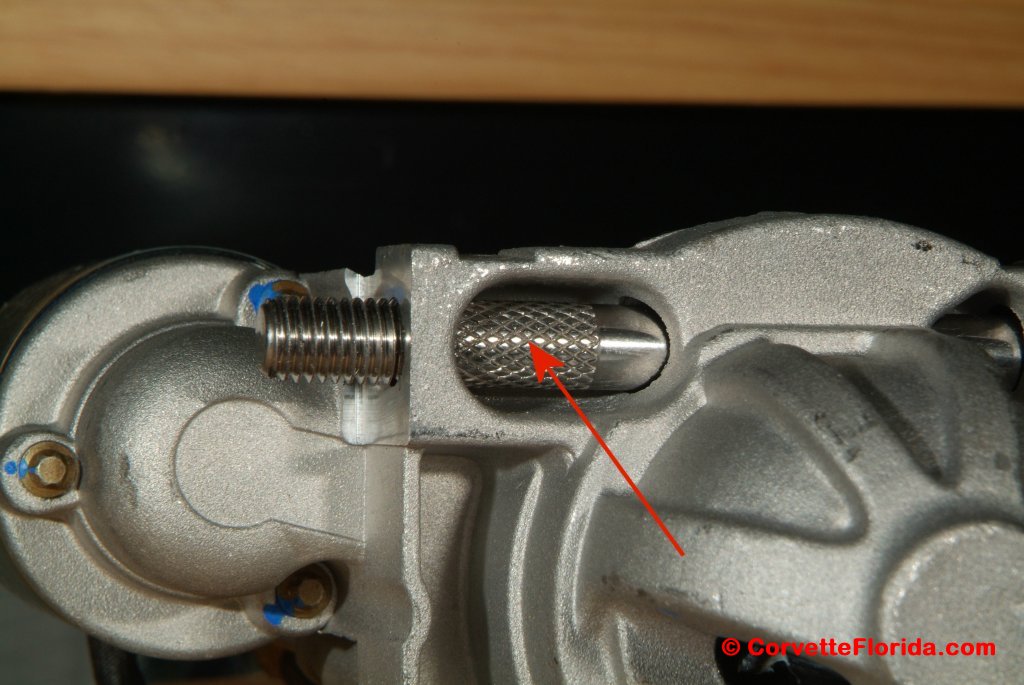

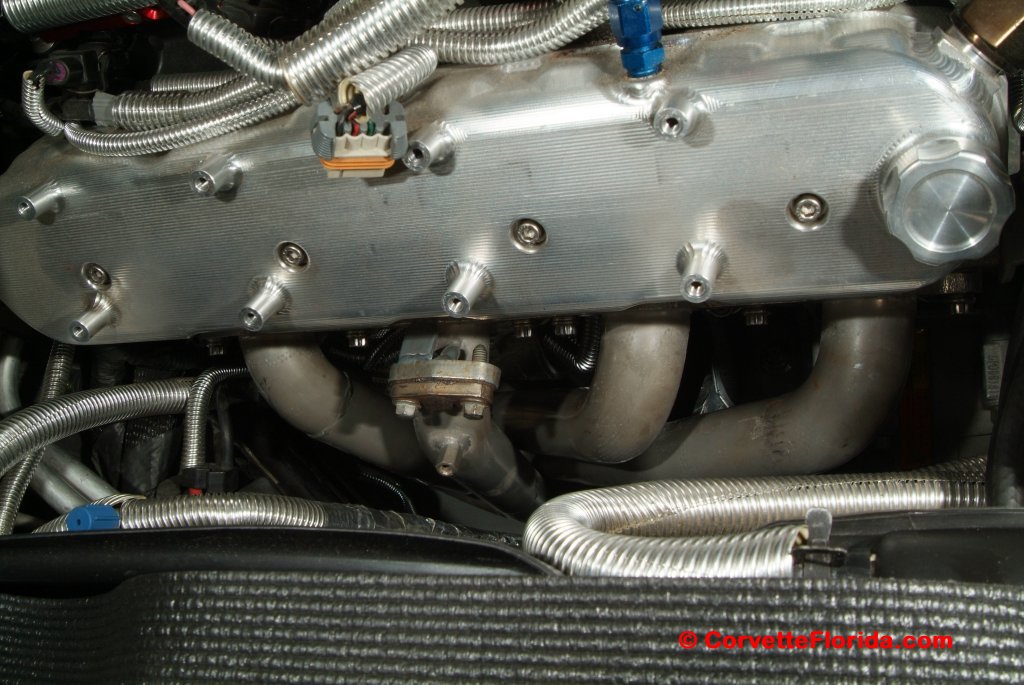

Wasn't too bad now that I had a starter that would actually fit properly, but I found that the ARP starter bolts I bought wouldn't fit within the starter mounting holes. Wouldn't work in my old starter neither, so it was definitely a problem with the bolts. The starter bolts are knurled on the end to help get a more precise fit on the engine block. Apparently they went too aggressive with the knurling and exceeded the tolerance of the holes. So I had to chuck the bolts up in my little baby lathe (sure wish I had gotten that big one I wanted) and trimmed a bit of metal off of the knurling till they fit. No big deal but sucked up an extra hour or two just doing that.

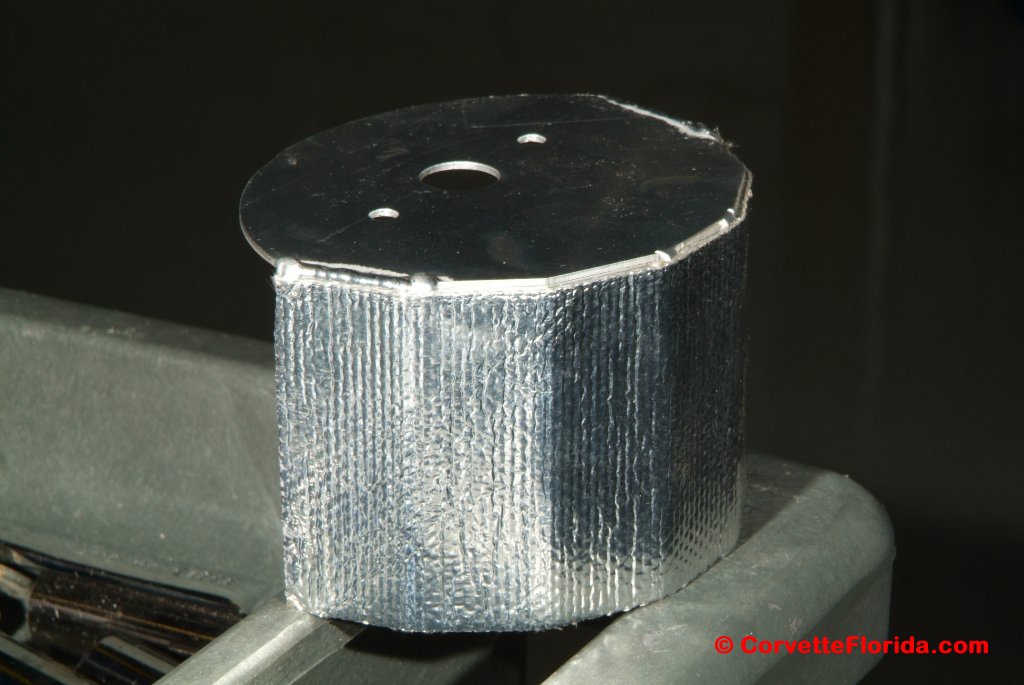

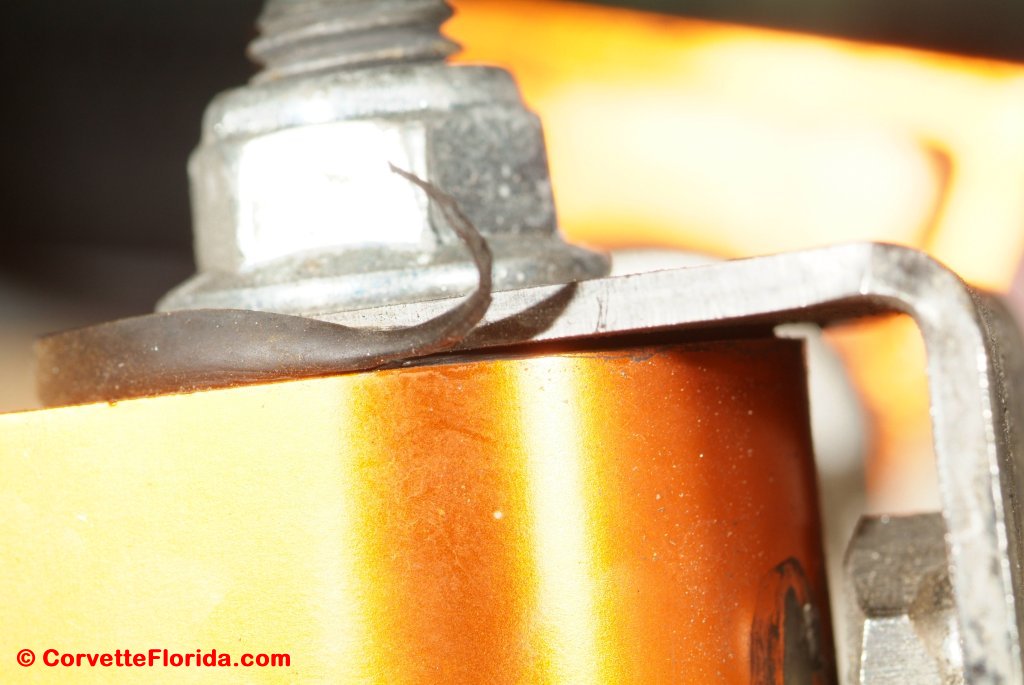

Then when I put on the heat shield around the starter, just on a hunch I broke out my multimeter and sure enough, that reflective coating is conductive. So I had to trim away the shield to make sure it wouldn't contact the hot leads on the starter. Would have been an interesting "smoke test" when I hooked the battery back up.

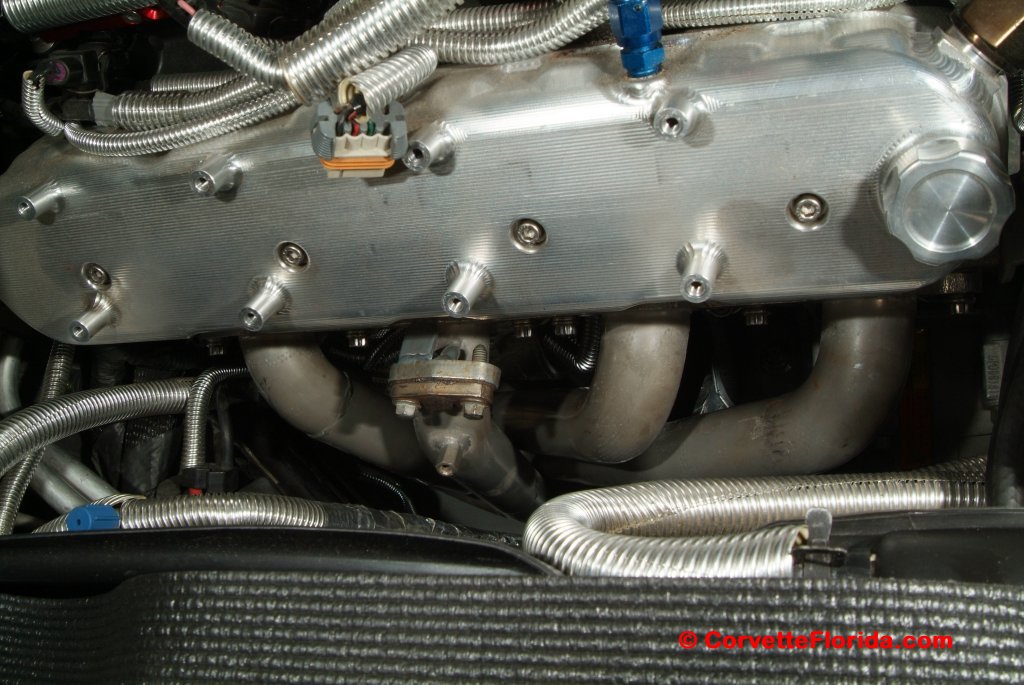

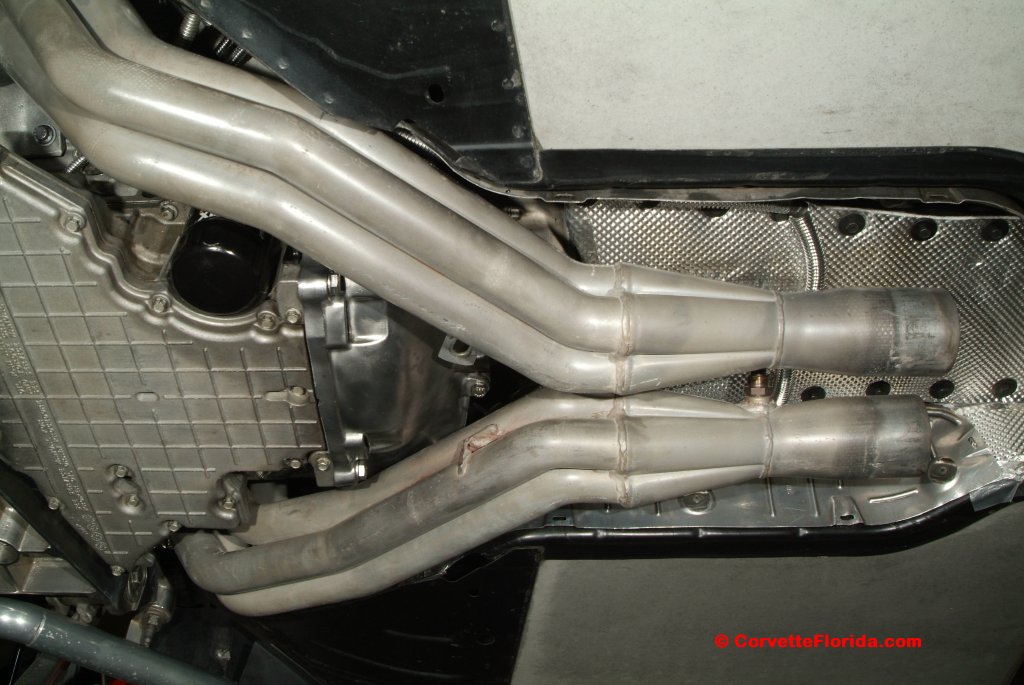

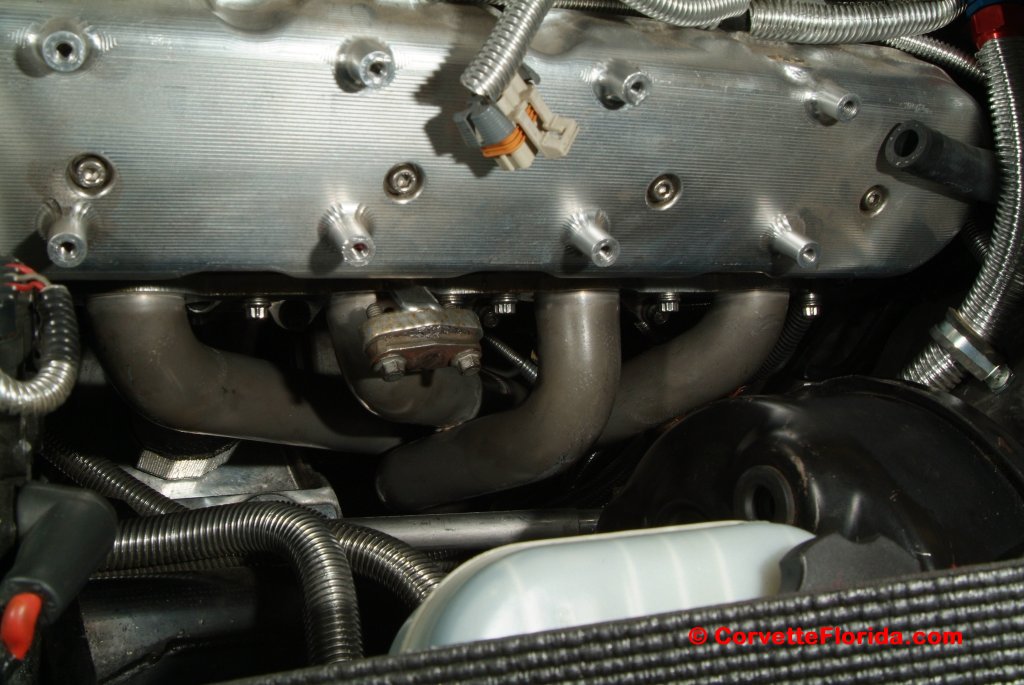

So the starter is in, and I also decided to go ahead and tackle bolting the headers back up. I really was not looking forward to putting the passenger side back in, figuring it was going to be a pain in the butt, with maybe the starter getting in the way and I would have to loosen it up or remove the heat shield just to get the header back up there. But easy as pie. I was actually shocked.

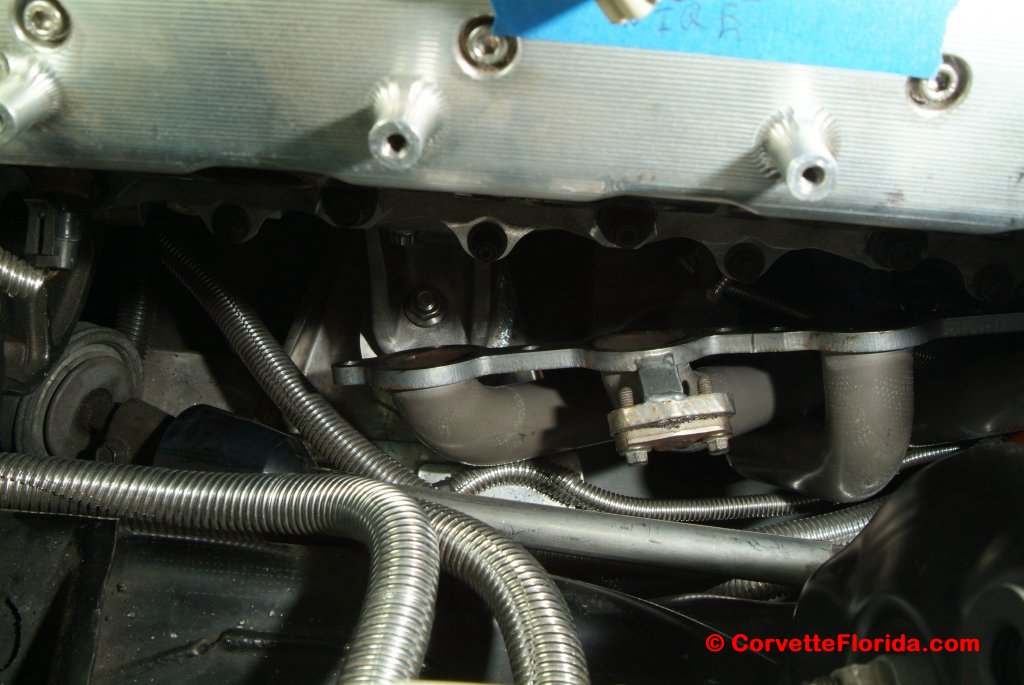

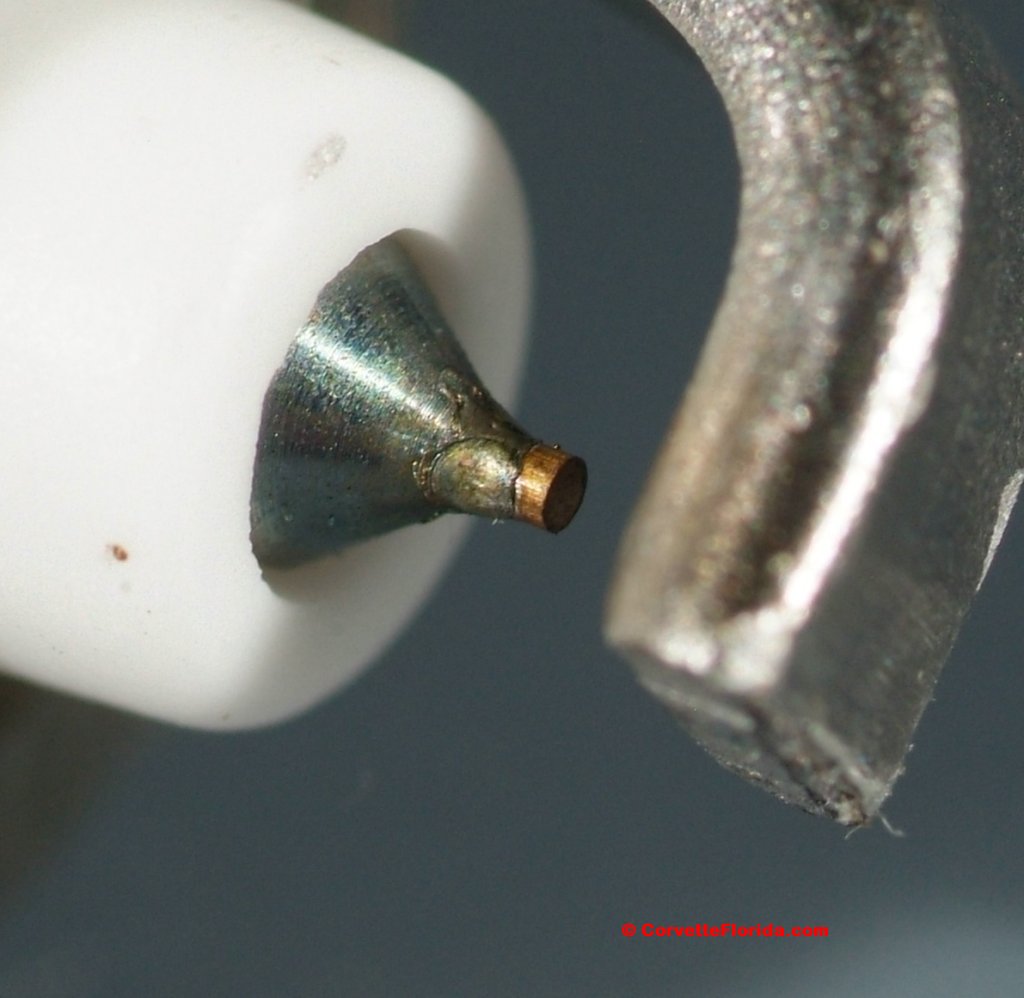

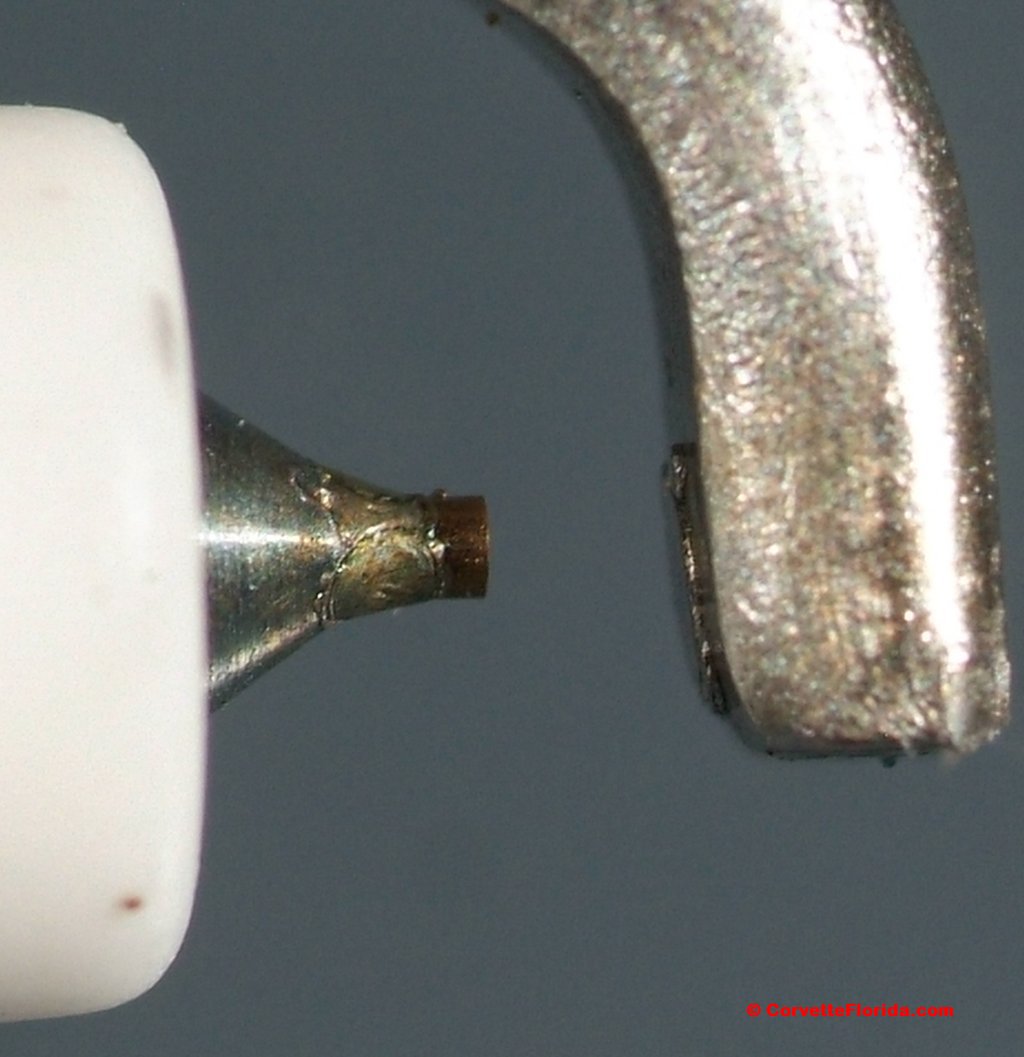

So I am looking at the new header gaskets I bought from Summit Racing, trying to figure out how they need to be oriented, and something just didn't look right about them.

Maybe it's me, but those two CAN'T be for the same engine. The LS7 exhaust ports are "D" shaped, which is why I bought them. Fortunately I had purchased a set of regular LS1/LS6 exhaust gaskets too, so those are the ones I had to use.

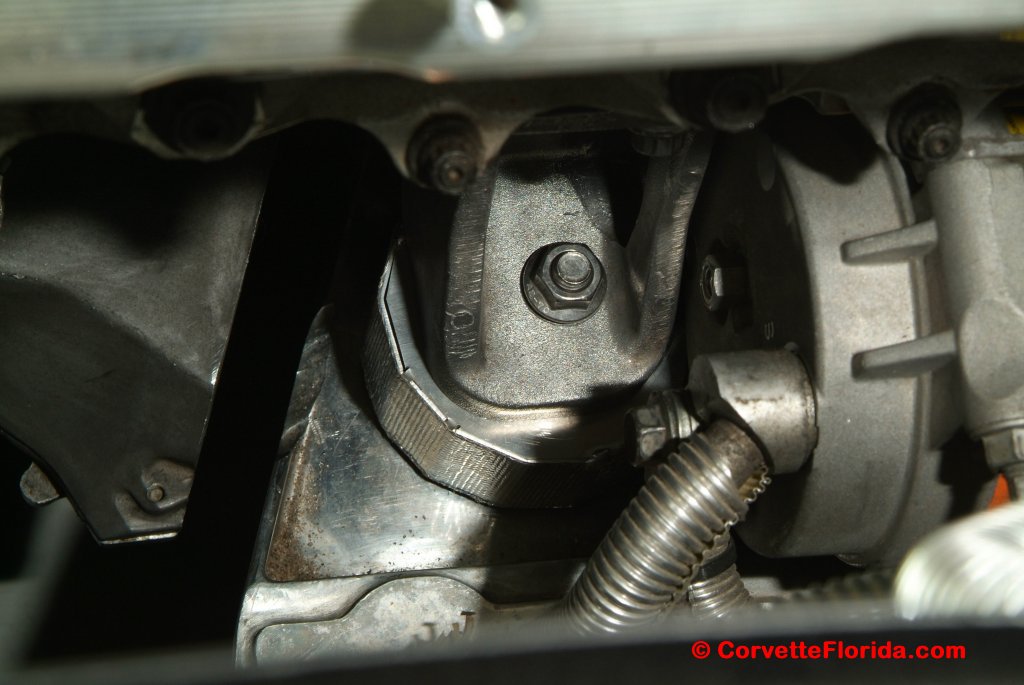

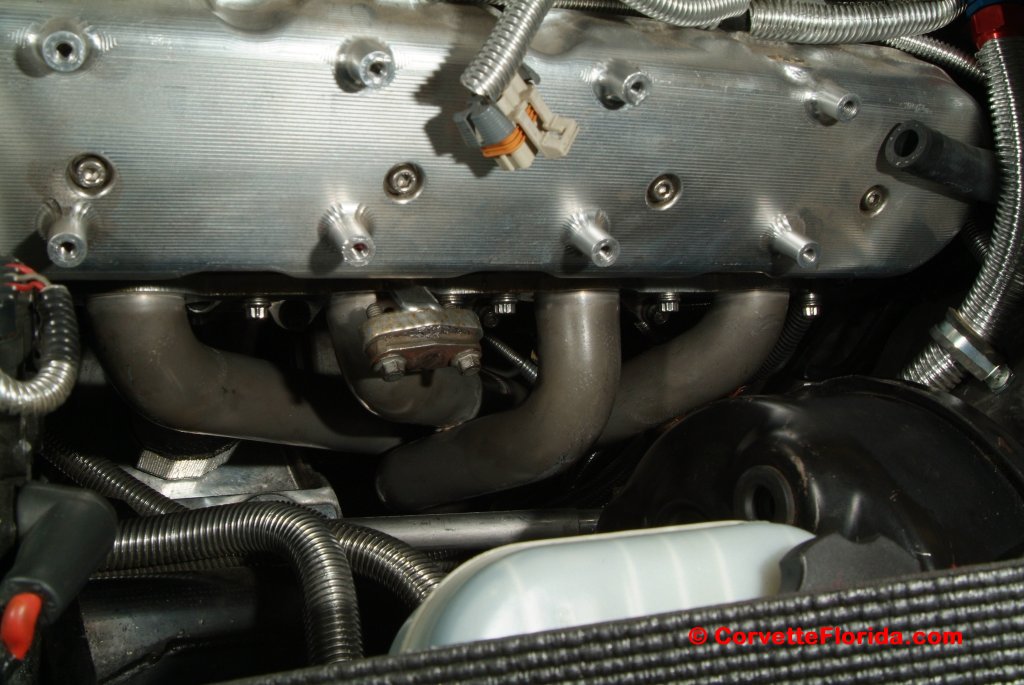

It was a struggled getting the bolts into the headers by myself, as it sure would have helped to have Connie maneuvering the lower end of the headers for me while I struggled getting the bolts in. But she is up in Delaware visiting family, so I was on my own with this. By using a jack to lift underneath while I worked from the top, I was able to get it done. Of course the most inaccessible bolt out of all of them was the most difficult. That's the one back near cylinder #7 at the very rear of the head. I was afraid I was cross threading it putting it in, but damn, that's the only way it was going in. It just felt harder to turn than the other ones. It's tightened down at 18 ft. lbs with Nord-Lock lock washers, so it should certainly be OK. I'll just check the torque on them later on, but those Nord-Locks are supposed to be THE things to use on stuff like this.

Oh yeah, and that Milwaukee battery powered ratchet is worth it's weight in gold in tight spots where you really can't turn a wrench very easily. :thumbsup:

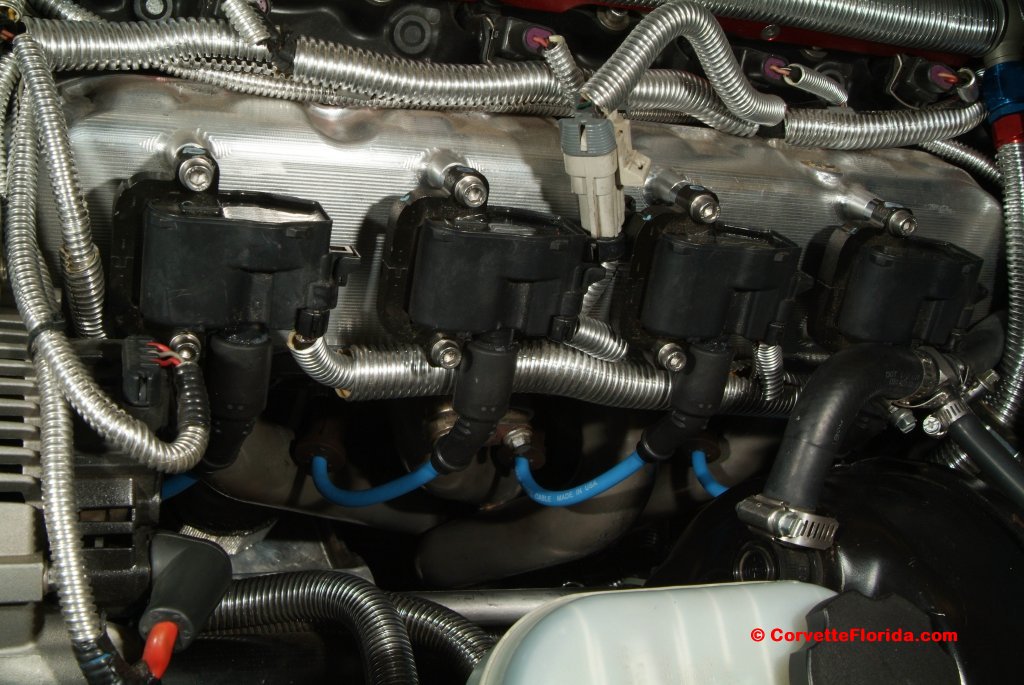

So anyway, tomorrow I'll either hook up the rest of the exhaust, or put the ignition stuff back in. Or maybe both if things go smoothly enough. So I'm thinking I'll be cranking it up maybe Sunday or Monday. Hopefully the smoke test won't actually produce any smoke and flames.... :ack2: