Well, I decided to go ahead and put the new shaft in the passenger side today, since the knuckle came in yesterday. Cleaned up the knuckle and started putting everything back together again.

I couldn't seem to get the half shaft back in the way I took it out, however. When I took it out, I had the knuckle still attached to the lower control arm via the lower ball joint. So I mounted the knuckle w/hub to the ball joint, as without the shaft in there, I could actually torque down that ball joint stud nut. But, it just was NOT going back in that way easily, though. I was afraid to struggle with it too much, as I certainly didn't want to rip one or both of the boots. So I had to disconnect the knuckle at the lower ball joint again and pull the knuckle off completely. So much for that method of install...

So I inserted the half-shaft into the differential, which only gave me a little bit of trouble. Just had to push on it sharply enough for it to slide over the clip on the shaft in the differential. With the knuckle disconnected from everything, it was then simple to just slide the shaft through the hub and then bolt it back up to the lower ball joint on the lower control arm. I got that nut on the lower ball joint as tight as I could using an open end wrench. Spec is something like 54 ft/lbs, so I'm guessing I was pretty close..

Seems like I had to do things twice, as it was tough getting the bolts holding the hub to the knuckle torqued to spec (96 ft/lbs) without first anchoring down the knuckle to the control arms to keep it still. Of course, this had to be done before mounting the knuckle onto the lower control arm, as the stud for the lower ball joint sits right in the way of one of the bolts holding the hub to the knuckle. I guess there are better and more fluid ways to do this without so much back tracking, but I just struggled through trying to do it as best I could figure.

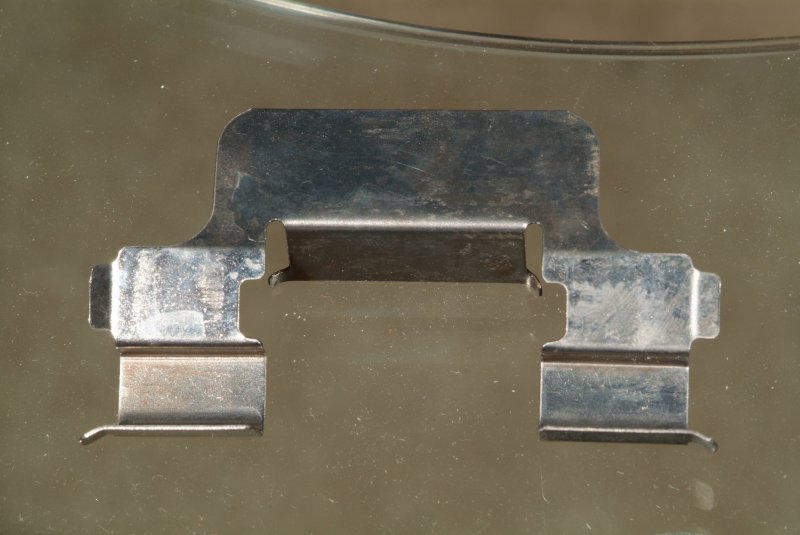

So I was feeling pretty good when I finally got the shaft installed into hub/knuckle and the differential, and bolted the knuckle down to the lower ball joint. That's when I noticed the emergency brake assembly laying on the floor near the old hub, and I thought, "Now how does that go back on there.....". Rats.... I had forgotten that the emergency brake assembly needs to go BETWEEN the hub and the knuckle. So that meant it all had to come back out again. Well, the half shaft could still stay in the differential, but since the other end of the shaft needed to come out of the hub, and the hub needed to come off of the knuckle, EVERYTHING else had to be undone...

But at least I hadn't put that end nut on the half shaft yet.

:ack2:

Oh well, I'll try that again tomorrow. I guess too much time passed between the days I took it apart and today when I wanted to put it back together, and I just plumb forgot a step. I checked the videos I took of the disassembly, and for some reason I didn't take any footage of the hub actually coming off of the knuckle and with that, the emergency brake assembly. Hopefully the orientation of everything will be easy to figure out tomorrow. Just have to make sure the wheel speed sensor cable is at the right place, as well as the cable connection for the emergency brake. Luckily I left the other side in place to look over....

I couldn't seem to get the half shaft back in the way I took it out, however. When I took it out, I had the knuckle still attached to the lower control arm via the lower ball joint. So I mounted the knuckle w/hub to the ball joint, as without the shaft in there, I could actually torque down that ball joint stud nut. But, it just was NOT going back in that way easily, though. I was afraid to struggle with it too much, as I certainly didn't want to rip one or both of the boots. So I had to disconnect the knuckle at the lower ball joint again and pull the knuckle off completely. So much for that method of install...

So I inserted the half-shaft into the differential, which only gave me a little bit of trouble. Just had to push on it sharply enough for it to slide over the clip on the shaft in the differential. With the knuckle disconnected from everything, it was then simple to just slide the shaft through the hub and then bolt it back up to the lower ball joint on the lower control arm. I got that nut on the lower ball joint as tight as I could using an open end wrench. Spec is something like 54 ft/lbs, so I'm guessing I was pretty close..

Seems like I had to do things twice, as it was tough getting the bolts holding the hub to the knuckle torqued to spec (96 ft/lbs) without first anchoring down the knuckle to the control arms to keep it still. Of course, this had to be done before mounting the knuckle onto the lower control arm, as the stud for the lower ball joint sits right in the way of one of the bolts holding the hub to the knuckle. I guess there are better and more fluid ways to do this without so much back tracking, but I just struggled through trying to do it as best I could figure.

So I was feeling pretty good when I finally got the shaft installed into hub/knuckle and the differential, and bolted the knuckle down to the lower ball joint. That's when I noticed the emergency brake assembly laying on the floor near the old hub, and I thought, "Now how does that go back on there.....". Rats.... I had forgotten that the emergency brake assembly needs to go BETWEEN the hub and the knuckle. So that meant it all had to come back out again. Well, the half shaft could still stay in the differential, but since the other end of the shaft needed to come out of the hub, and the hub needed to come off of the knuckle, EVERYTHING else had to be undone...

But at least I hadn't put that end nut on the half shaft yet.

:ack2:

Oh well, I'll try that again tomorrow. I guess too much time passed between the days I took it apart and today when I wanted to put it back together, and I just plumb forgot a step. I checked the videos I took of the disassembly, and for some reason I didn't take any footage of the hub actually coming off of the knuckle and with that, the emergency brake assembly. Hopefully the orientation of everything will be easy to figure out tomorrow. Just have to make sure the wheel speed sensor cable is at the right place, as well as the cable connection for the emergency brake. Luckily I left the other side in place to look over....