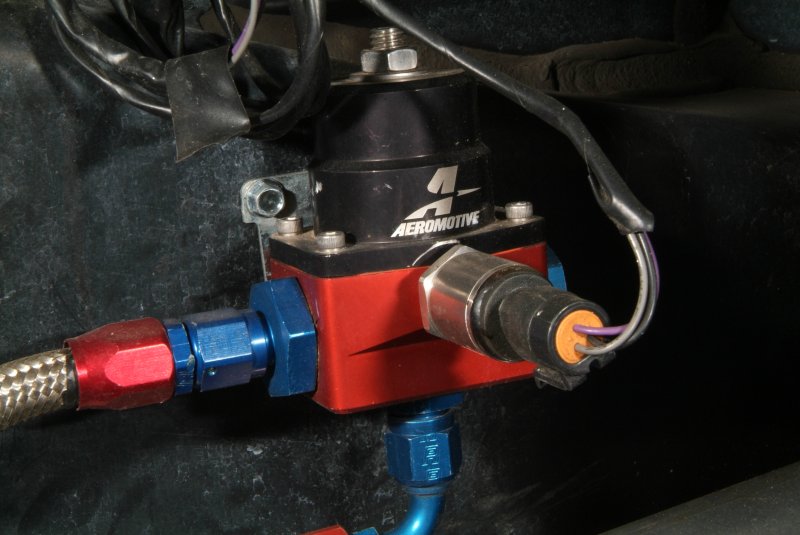

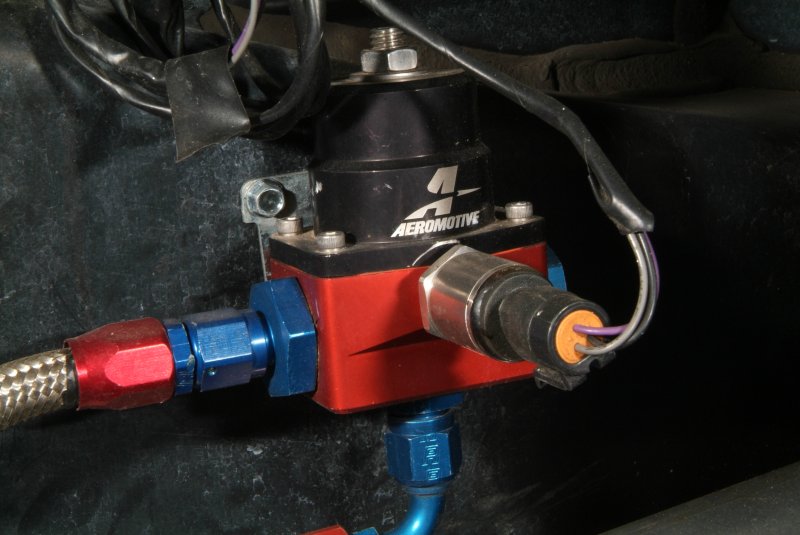

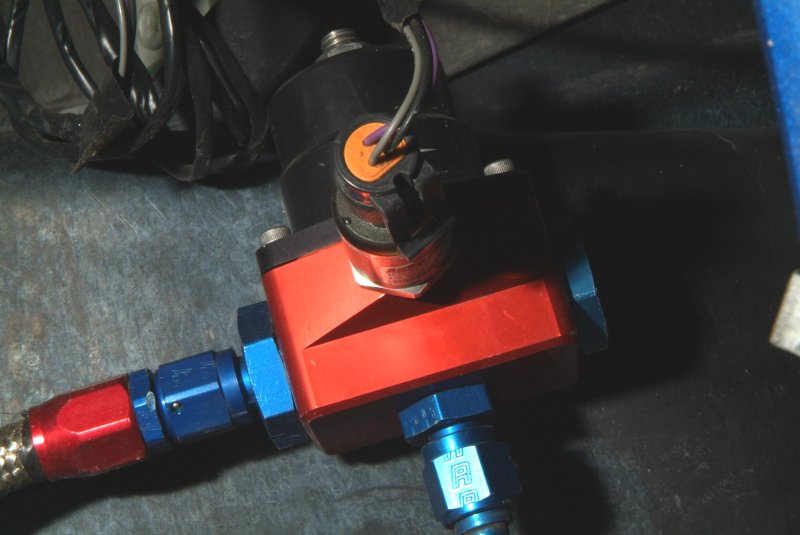

Here'e the Aeromotive fuel pressure regulator that is on my car:

Now here's a pic of what I believe is the same one from Aeromotive's website.

The obvious difference is that silver colored vacuum nipple coming off from the right hand side....

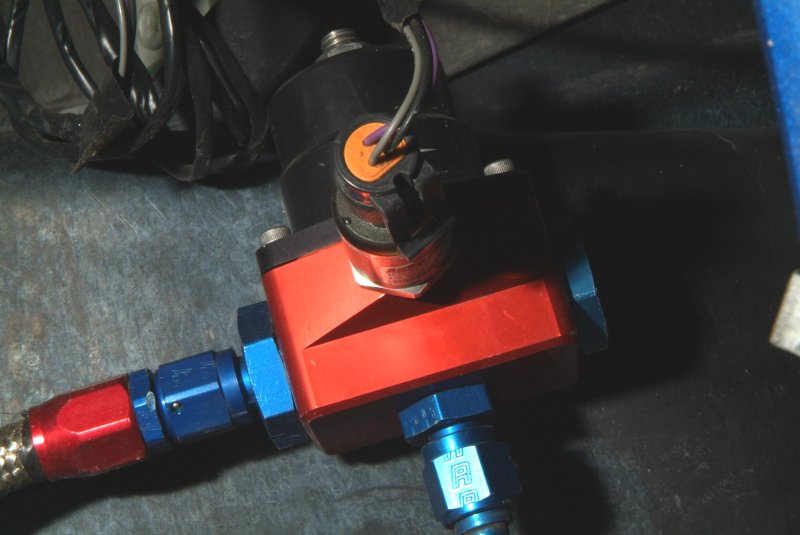

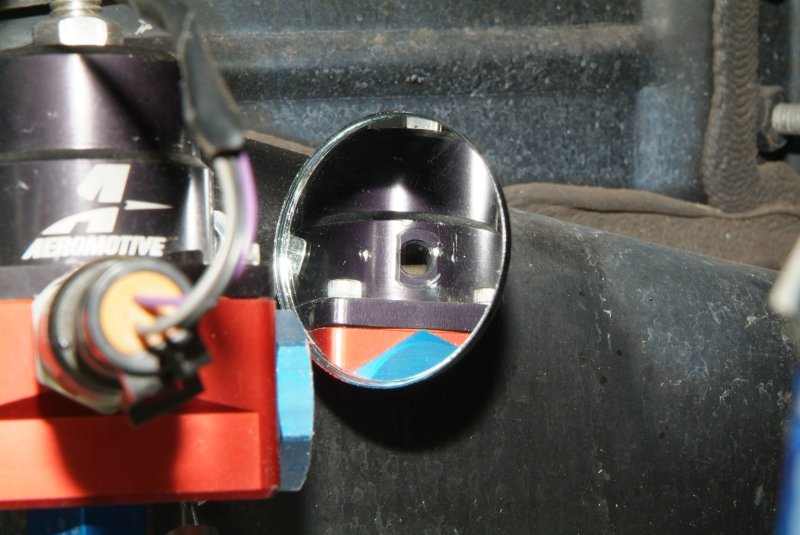

So I went and took a closer look at mine to see what I had there (or HADN'T there, in this case):

Hmm, not only is there nothing on the vacuum nipple, but the nipple itself is gone. Now I have to figure out if I NEED to have that vacuum line hooked up or not for the regulator to function properly.

While I was at it, I took some photos of the connectors on the fuel lines that I have to relocate.

Here's the bundle of lines at the stock fuel pump:

And here's the specific line that I need to change from the AN-06 line that is now on it to the AN-08 line that will come from the out side of the Aeromotive pump:

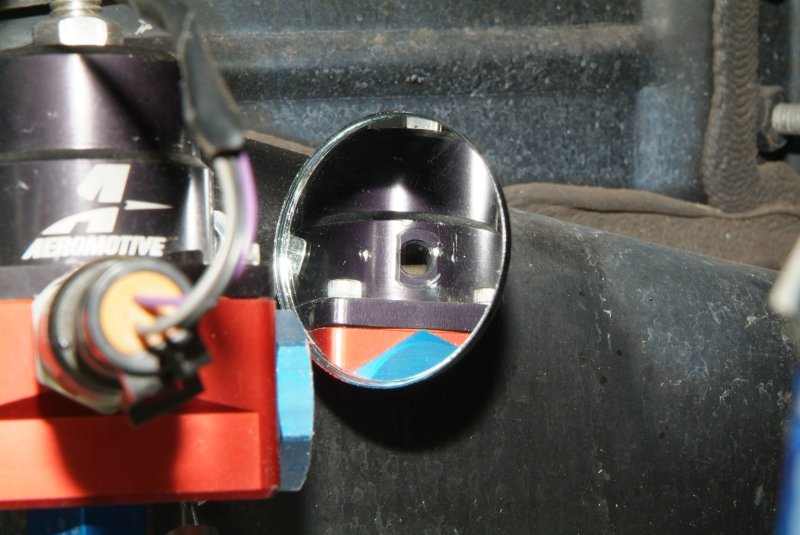

And here's that AN-08 out line that is on the Aeromotive pump:

Doesn't look like it will be too much of a chore, but I DO need to figure out what to do about the fuel filter issue, since no one apparently thought my car needed one......

Now here's a pic of what I believe is the same one from Aeromotive's website.

The obvious difference is that silver colored vacuum nipple coming off from the right hand side....

So I went and took a closer look at mine to see what I had there (or HADN'T there, in this case):

Hmm, not only is there nothing on the vacuum nipple, but the nipple itself is gone. Now I have to figure out if I NEED to have that vacuum line hooked up or not for the regulator to function properly.

While I was at it, I took some photos of the connectors on the fuel lines that I have to relocate.

Here's the bundle of lines at the stock fuel pump:

And here's the specific line that I need to change from the AN-06 line that is now on it to the AN-08 line that will come from the out side of the Aeromotive pump:

And here's that AN-08 out line that is on the Aeromotive pump:

Doesn't look like it will be too much of a chore, but I DO need to figure out what to do about the fuel filter issue, since no one apparently thought my car needed one......