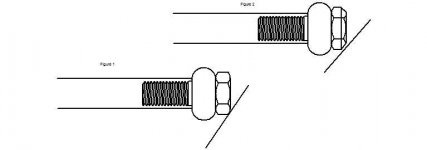

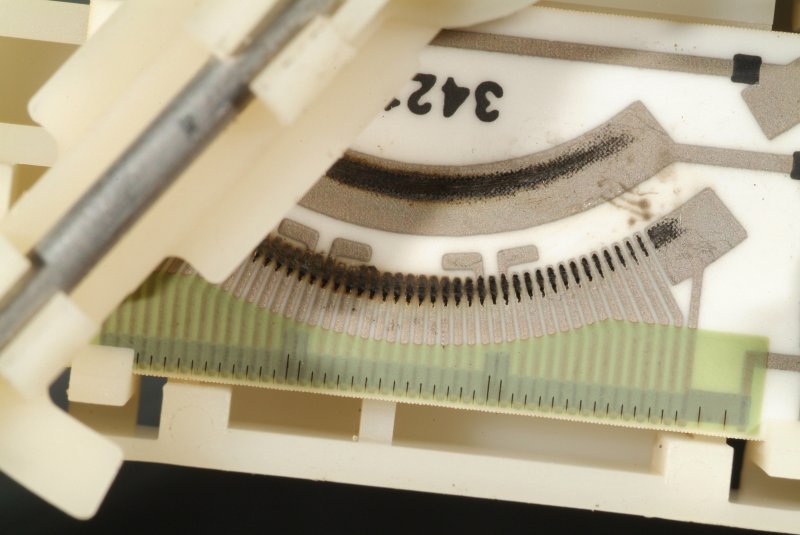

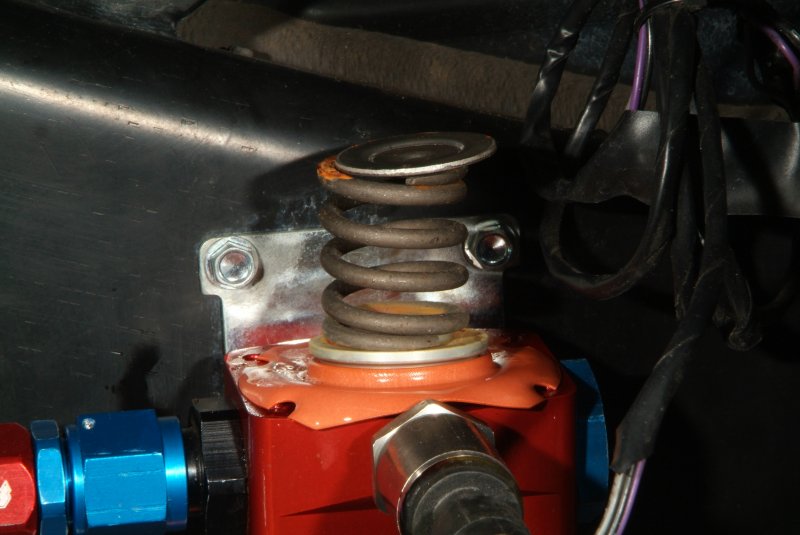

Monday was pretty much allocated to trying to figure out what to do about that fuel leak at the banjo fitting. I think the washers I have on order will fix that, though, as long as they aren't too thick and then cause an issue with clearance with the firewall. The guy at NukePerformance told me the copper washers will work, but I need to lube the threads on the bolt going into the end of the fuel rail and REALLY crank down on it to tighten it. He estimates around 120nm, which is 88.5 ft/lbs. So I guess it depends on what those new aluminum washers look like as to what method I will try first.

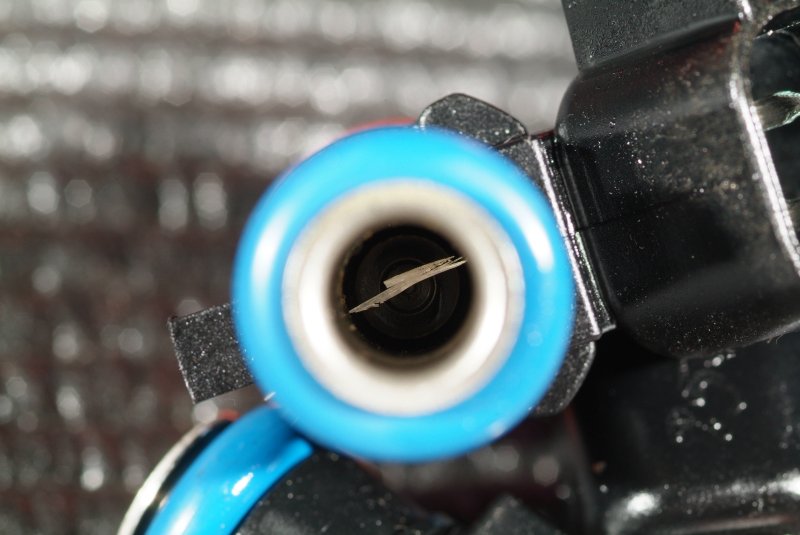

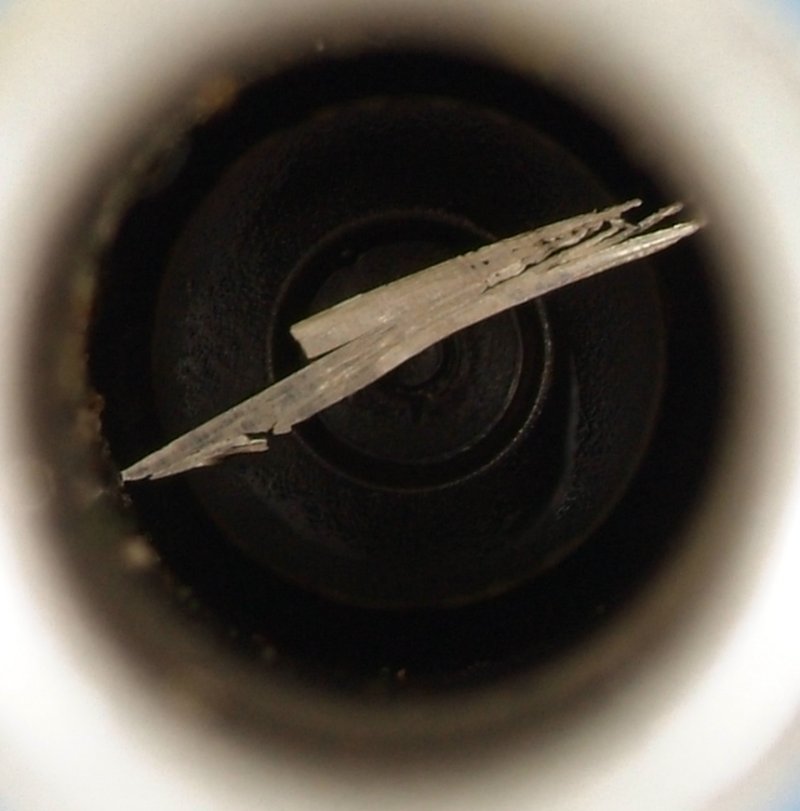

Since I was already slapped around with the fuel leak, I decided to go ahead and take a stab at that stuck brake bleeder screw. Figured I might as well get 100 percent pissed off today if it was going to be another problem........ I mounted the knuckle, hub, and the brake hardware so I would have the caliper solidly mounted before putting a wrench to the bleeder screw. Used a 10mm offset box wrench so I had as much purchase as possible on the screw, and gave it a tug. Loosened right up for me, with barely a whimper. I guess a couple of days soaking it with PB Blaster and tapping it with the hammer did the trick. So I was able to push the caliper pistons back and then install the new brake rotor and pads. So now I've just got the driver's side front hub and brakes to do. I may start on that on Tuesday even if those banjo washers come in. I'm not sure how long that banjo fitting will be leaking gasoline and how low the pressure needs to drop before it stops. I may have to crack open a hose fitting to relief the pressure completely so everything can dry out more quickly. I feel like I'm really bucking fate and skirting around just torching that car with this fuel line stuff.... All it would take is a little tiny spark at the wrong time. But I'm thinking (on the positive side) that those open fuel lines going to the passenger side fuel tank were pretty likely the cause of the gasoline smell all along. Excluding the leaking fuel injector early on, of course.

But now that has me thinking about the passenger side fuel tank. I doubt Aaron ever really filled up my gas tanks while he had my car, and certainly neither did Harwood, so I wonder if it's been dry all this time? When I had the fuel pumps running on Monday, the passenger side was gurgling like crazy, so I'm wondering what exactly would happen if the driver side was the only one with gasoline in it, and I then start up the pumps with the fuel lines set up correctly. I'm wondering if perhaps some fuel gets pumped over to the passenger side from the driver's side in a case like that to try to balance both tanks. I didn't think to look at the fuel gauge to see if it changed any.

Speaking of which, how in the world did my fuel gauge even work at all? I believe BOTH tanks have level sensors in them, and there is just no way that both tanks had the same amount of fuel in them. :thinkin: Guess I've still got lots more to learn about this stuff.

Since I was already slapped around with the fuel leak, I decided to go ahead and take a stab at that stuck brake bleeder screw. Figured I might as well get 100 percent pissed off today if it was going to be another problem........ I mounted the knuckle, hub, and the brake hardware so I would have the caliper solidly mounted before putting a wrench to the bleeder screw. Used a 10mm offset box wrench so I had as much purchase as possible on the screw, and gave it a tug. Loosened right up for me, with barely a whimper. I guess a couple of days soaking it with PB Blaster and tapping it with the hammer did the trick. So I was able to push the caliper pistons back and then install the new brake rotor and pads. So now I've just got the driver's side front hub and brakes to do. I may start on that on Tuesday even if those banjo washers come in. I'm not sure how long that banjo fitting will be leaking gasoline and how low the pressure needs to drop before it stops. I may have to crack open a hose fitting to relief the pressure completely so everything can dry out more quickly. I feel like I'm really bucking fate and skirting around just torching that car with this fuel line stuff.... All it would take is a little tiny spark at the wrong time. But I'm thinking (on the positive side) that those open fuel lines going to the passenger side fuel tank were pretty likely the cause of the gasoline smell all along. Excluding the leaking fuel injector early on, of course.

But now that has me thinking about the passenger side fuel tank. I doubt Aaron ever really filled up my gas tanks while he had my car, and certainly neither did Harwood, so I wonder if it's been dry all this time? When I had the fuel pumps running on Monday, the passenger side was gurgling like crazy, so I'm wondering what exactly would happen if the driver side was the only one with gasoline in it, and I then start up the pumps with the fuel lines set up correctly. I'm wondering if perhaps some fuel gets pumped over to the passenger side from the driver's side in a case like that to try to balance both tanks. I didn't think to look at the fuel gauge to see if it changed any.

Speaking of which, how in the world did my fuel gauge even work at all? I believe BOTH tanks have level sensors in them, and there is just no way that both tanks had the same amount of fuel in them. :thinkin: Guess I've still got lots more to learn about this stuff.