In reference to the earlier posts about the vacuum line to the fuel pressure regulator, the guy who is going to be doing my tuning recommends that I DO have the vacuum line hooked up.

I've been doing some reading about this, and apparently there are two ways to control the issue of variable fuel amounts needed from idle to WOT. The problem is that there is MORE vacuum available at the fuel injectors at idle than at WOT, even to the point where at IDLE, the injectors themselves are actually subject to a suction effect that will draw out more fuel than injectors simply being opened at zero vacuum. I'm still trying to wrap my brain around some of this so bear with me.

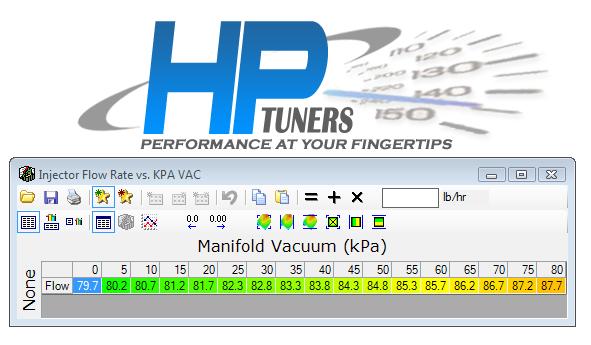

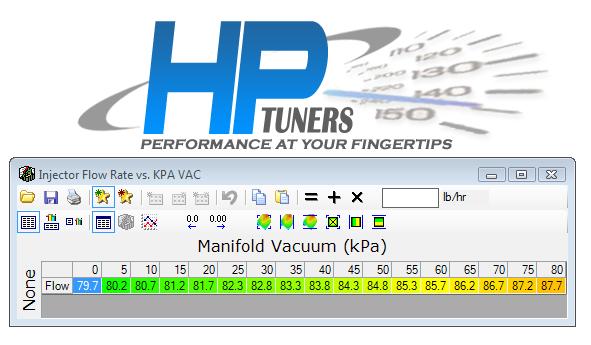

Anyway, there are two methods used to adjust the actual amount of fuel that the PCM calculates for the injectors to provide that will be variable depending on the vacuum inside the manifold and referenced via the MAP sensor. One method is via the vacuum line going to the fuel pressure regulator which will then mechanically control the amount of fuel pressure it provides to the fuel rails. In this case, the regulator provides less fuel pressure at high vacuum levels and increasingly more pressure as vacuum is reduced and even going into positive pressure (boost for forced induction). The other method, and the one that is used in the stock C5 Corvettes (probably other generations, too), is to do this programmatically via something called the Injector Flow Rate Table. Which looks something like this...

What this table does is programmatically act like what the vacuum line does that would go to the fuel pressure regulator. That is, it adjusts the amount of fuel referenced to the vacuum in the intake manifold that the PCM commands the fuel injectors to deliver to the cylinders. As you can see in the table above, the values are variable depending upon vacuum in the intake manifold. If the vacuum line were hooked up to the fuel pressure regulator, than those values would all be the same, which would be the actual flow rate of the injectors.

Now there is a lot of negative logic going on, that I am still trying to come to grips with, but basically kPa is actually PRESSURE, so 0 kPa means zero pressure, which means MAX vacuum (idle), and the value at 80 kPa means max pressure (up to sea level barometric pressure), which means zero vacuum (WOT - or pretty much ambient barometric pressure). Basically the amount of air coming into the engine has stabilized to where all the air needed is being provided.

Also note that the higher the values in the cells in the table, the LOWER amount of fuel being commanded to the fuel injectors. In effect, the table TELLS the PCM the flow rate of the injectors for a given amount of vacuum. The fuel injectors I have in that engine are rated at 72 lb, so it appears that this table is fooling the PCM in my car into thinking that the injectors are LARGER than they actually are, so that it will command a smaller duration opening of the injectors as the PCM tries to calculate how much fuel that the injector needs to deliver to the cylinder, and therefore run leaner than if the 72 lb values were being used. Since the PCM thinks the injectors are larger, it needs to hold the duration of the injector being opened a LESSER amount of time. So, in effect, the smaller the number in that table the longer the duration, and therefore MORE fuel, being commanded to the fuel injectors. Like I said, NEGATIVE logic here...

Now, looking at that IFR table above, it's really confusing, at least to me. 100 kpa is actually 14.5 psi, which is pretty close to sea level air pressure (14.7 psi). So the assumption must be that the furtherest right hand cell must be WOT, and the left most cell must be idle, IF we are really talking about kPa values for that table. But if this is true, the VALUES in those cells are the REVERSE of what they should be. At idle, the value in that cell is 79.7, and at WOT, that cell is 87.7. So what this means is that the PCM is being hoodwinked into believing that thru all levels of manifold vacuum, the injectors are LARGER than the 72 lbs injectors I actually have. And more to the point of my confusion, the injector values at idle will deliver MORE fuel than the injector values indicated at WOT. Remember, smaller values will deliver MORE fuel than the larger values in that table.

The only way this table does make sense to me is if those cell labels are NOT actually kPa, but instead a relative VACUUM level, meaning that the table actually is indicating WOT at the left most cell, and IDLE at the rightmost cell. Then the values in those cells DO make sense, with less fuel being provided at idle and MORE fuel being provided at WOT.

I know the above is probably a jumbled mess, but I'm just trying to figure this all out, and maybe trying to EXPLAIN it will help me UNDERSTAND it a little better.... So if anyone else can figure this out and explain it to me, PLEASE do.