Well, today didn't go as well as I had hoped working on the car. The passenger side header came out without too much trouble. And I was able to get the starter out. Had to turn it around to get to the cables, though.

But the driver's side is really fighting me HARD. And I found out that the insulating wrap I put on the headers wants to just disintegrate and fall apart on me. Hope I didn't breath in too much of that stuff before deciding to put on a face mask. Already had goggles on, since I was figuring on getting sand falling out of nooks and crannies. So after tugging and twisting on the that driver's side header for a while, I decided it was time to just walk away from it for a bit....

So that's where it is now. I may have to re-evaluate how badly I want to replace that broken Pfadt motor mount on that side. I think I will be able to get the one on the passenger side replaced (

knock on wood) and surely get the new starter in there. But that driver's side might be beyond my patience level. No sure I want to have to do major surgery just to get that header out of there.

Damn, my arms itch like crazy from that disintegrating insulation. Yeah, I hope I didn't breath much of it......... :ack2: I removed nearly all of the insulation from that driver side header so I could see better what it was hanging up on, and I did have the face mask on at that time. But I guess I should have worn a long sleeved shirt too.

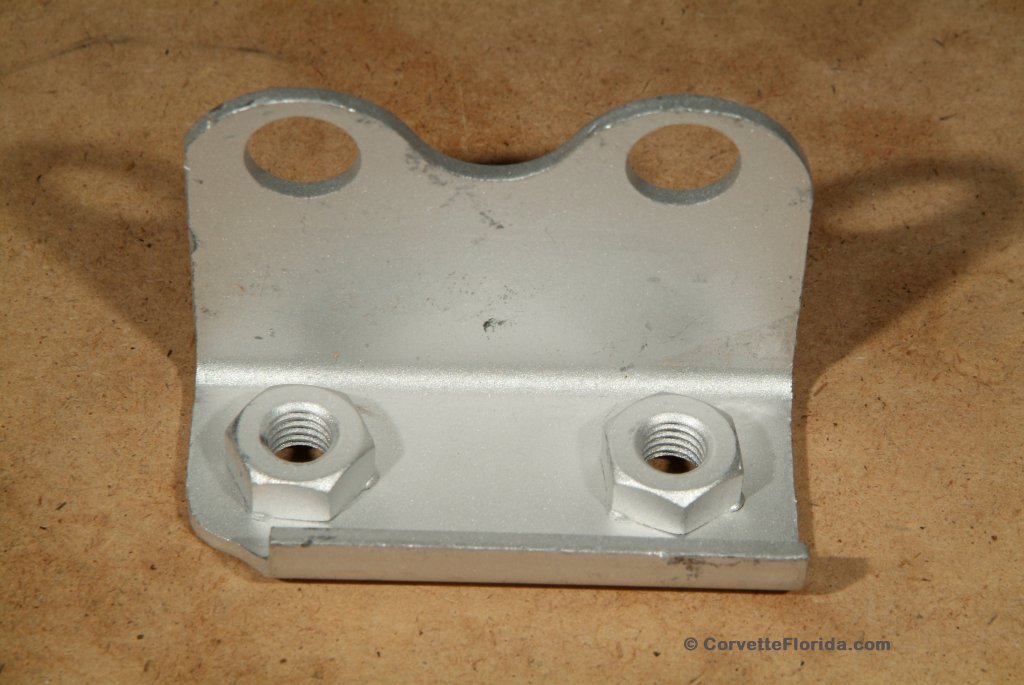

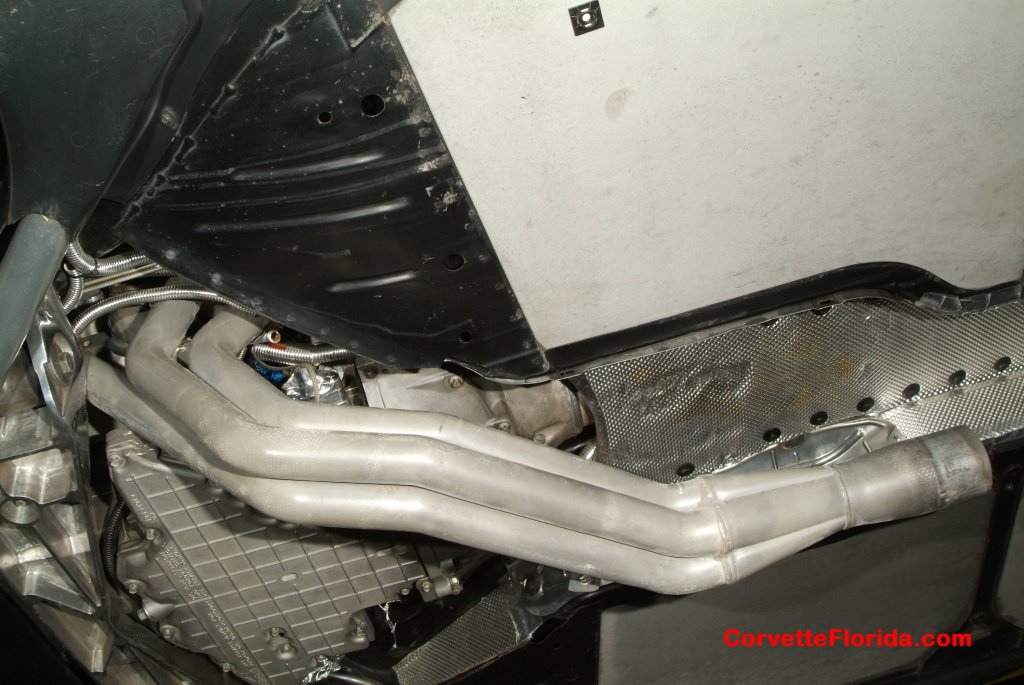

Oh yeah, when I was pulling the exhaust pipes off of the headers, I was a bit worried about dropping the pipes as I tugged and wiggled the back end of them to get them off of the headers. So I came up with a solution to support the pipes.....

Yeah, certainly an overkill use for a transmission jack, but it was just sitting there.............

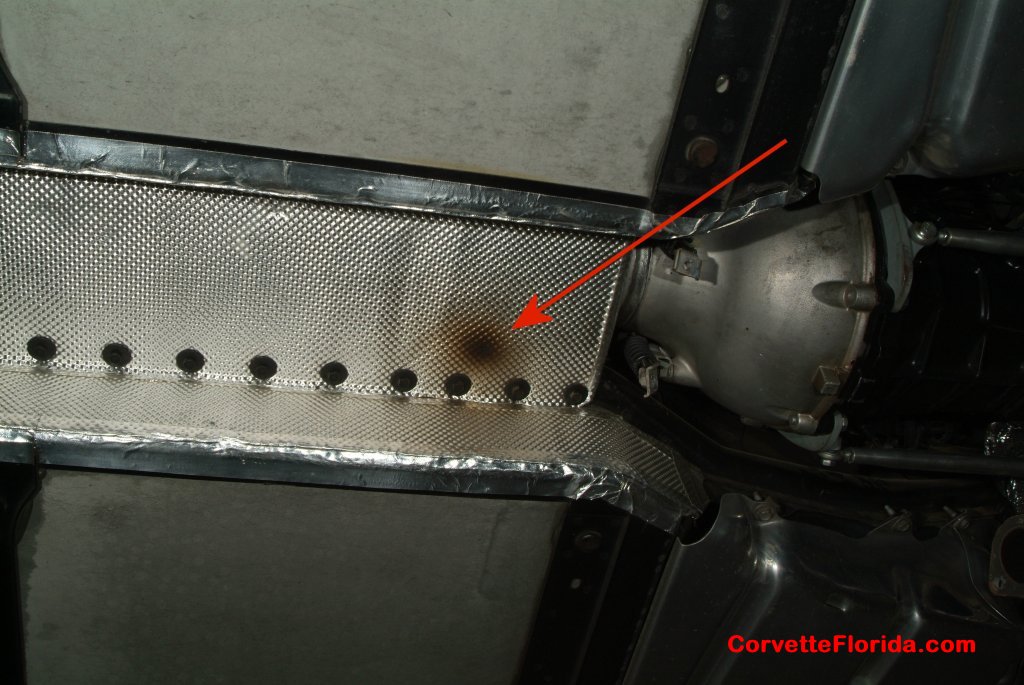

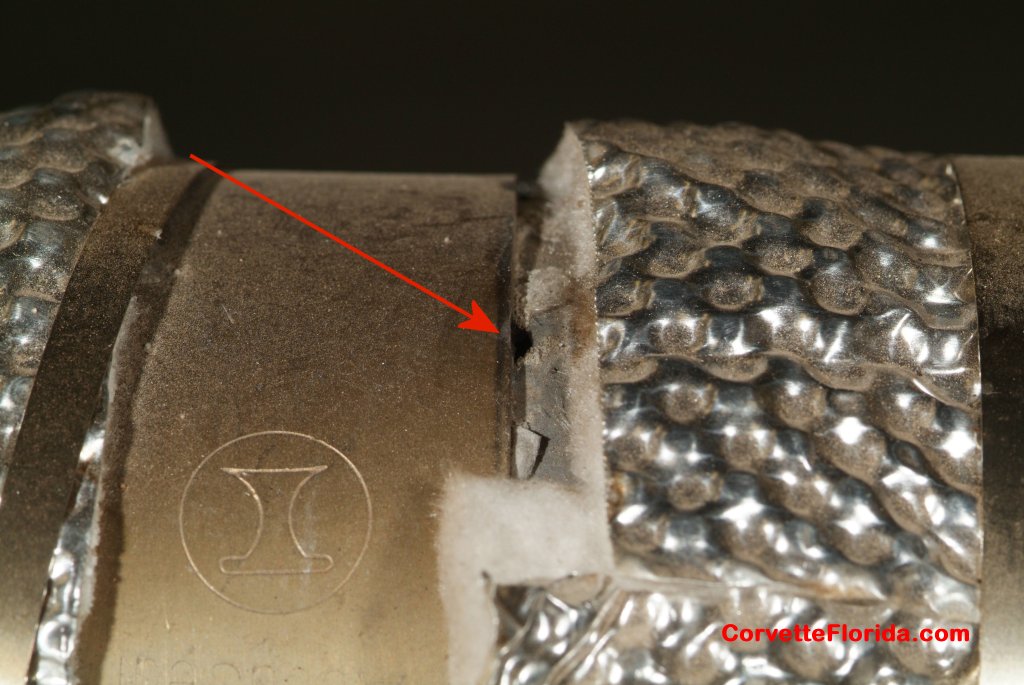

When the pipes were out, I noticed what looked like a burn mark on the underside of the tunnel plate...

Yeah, looks like I didn't have the clamp on right to cover that hole in the flange.....

THAT should be an easy enough fix when I put it all back together.